RWP

1 kW

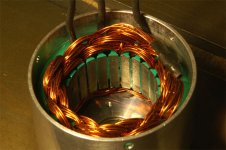

My Astro 3220 has goo inside and was measured at 230 degrees Fahrenheit  Anyone experience this kind of temperature with a 3220?

Anyone experience this kind of temperature with a 3220?

The HV 160 was measured at 205 degrees Fahrenheit

My temp measuring device is a cheap small hold in your hand type. But both the motor and controller are far too hot to touch.

Matt said: "when the laminations were epoxied in place, some epoxy chips remained at the bottom of the motor and eventually worked their way between the rotor and stator. Just clean (sand?) the epoxy off the stator and clean it out of the can and put it back together."

I took the 3220 apart once already and sanded as directed. Now it's happened again. The motor stator epoxied to the rotor. Anyone else have this problem and if so what did you do to fix it?

Is this a common issue with 3220's? Considering I am getting it ready for Willow Springs in a few days this is troubling for me.

I had some heat shrink that covered the connection shrunk to wire and loose at connector, kink of like a jacket that protected the joint that was loose and slipped over the joint. This heat shrink got so hot it closed over the joint so I have to cut it off.

Also my HV160 was measured at 205 degrees Fahrenheit and shuts down, at least I think when the HV160 gets too hot it automatically turns itself off - is this correct? What is the shut down temp for the HV160? Anything I should know about here? I was thinking of putting two 60mm 12v computer cooling fans blowin directly at the HV160 - do you think this will help?

I am wondering if the epoxy drag in the motor is causing the motor and thus the controller to run hot?

It's now geared to run at about 40 mph with a 24" rear wheel - so I don't think it's geared too high.

Any suggestions or observations are greatly appreciated.

The HV 160 was measured at 205 degrees Fahrenheit

My temp measuring device is a cheap small hold in your hand type. But both the motor and controller are far too hot to touch.

Matt said: "when the laminations were epoxied in place, some epoxy chips remained at the bottom of the motor and eventually worked their way between the rotor and stator. Just clean (sand?) the epoxy off the stator and clean it out of the can and put it back together."

I took the 3220 apart once already and sanded as directed. Now it's happened again. The motor stator epoxied to the rotor. Anyone else have this problem and if so what did you do to fix it?

Is this a common issue with 3220's? Considering I am getting it ready for Willow Springs in a few days this is troubling for me.

I had some heat shrink that covered the connection shrunk to wire and loose at connector, kink of like a jacket that protected the joint that was loose and slipped over the joint. This heat shrink got so hot it closed over the joint so I have to cut it off.

Also my HV160 was measured at 205 degrees Fahrenheit and shuts down, at least I think when the HV160 gets too hot it automatically turns itself off - is this correct? What is the shut down temp for the HV160? Anything I should know about here? I was thinking of putting two 60mm 12v computer cooling fans blowin directly at the HV160 - do you think this will help?

I am wondering if the epoxy drag in the motor is causing the motor and thus the controller to run hot?

It's now geared to run at about 40 mph with a 24" rear wheel - so I don't think it's geared too high.

Any suggestions or observations are greatly appreciated.