I'm not the guy to talk about Cromotor, hopefully some expert/user will put his 2 cents on the thread.

that's what I've quickly collected and then calculated around here (ES):

Cromotor V3 stock

Kv: 9.3 rpm/V

Kt: 1.0268 Nm/A

Rm: 0,084Ω (but there are also different reports from 0.090 to 0.075 :? )

Wt: 12.2 Kg

Km: 3.54 Nm/W^.5 (Kt/Rm^.5)

Specific Km: 0.29 Nm/W^.5/Kg

MAx Cont. Amps: ? (but you suppose 100A and anyway is easily limited there by the available controllers)

Specific torque: 8.41 Nm/Kg (Kt*Amax/Wt)

is that believable? how long?

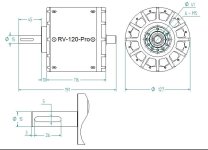

Revolt RV.120 stock

Kv: 45 rpm/V

Kt: 0,2122 Nm/A

Rm: ? Ω

Wt: 4.3Kg

Km:

Spec. Km:

Max Cont. Amps: ? (but again you suppose 100A)

Specific torque: working from Miles calculations http://endless-sphere.com/forums/viewtopic.php?f=28&t=64342#p964803 it is believable a 3.3(Nm/Kg) specific Torque to sustain 65mph (67Nm/4.72ratio => 14.19Nm/4.3Kg) supposedly on an approx. 2.1m wheel circumference, with 100Kg grand and "standard" vehicle/environment conditions)

Now, Assuming 100A continuous instead of the 67A on Miles example (14.2Nm/0.2122Nm/A=66.87A) the specific torque would rise up to 5 Nm/Kg, the question again is:

is it still believable....?

Having Rm and no loads from the manufacturer should be normal.....or :?

Looking at a close motor in weight and claimed performances from the "RC" world I found nothing really available and/or with a good datasheet. A bit over (in every field), and inrunner there's the

Astro 4535 @5.3Kg 4T Wye (160A @100V test)

Kv: 80 rpm/V

Kt: 0.119 Nm/A

Rm: 0.023 Ω

Wt: 5.3Kg

Km: 0.784 Nm/W^.5

Spec. Km: 0.148

Max Cont. Amps: 160 A (at least)

Specific torque: 3,59 Nm/Kg

Sorry to be that long It has been useful for me to remind me rules and formulas....

In COnclusion My feel is that both these motors (even if the cromo specs are a bit unbelievable from my unexpert point of view) Should deliver exciting ad Huge torque and power amounts, probably over even the insane "needs" of the superMotoBicycle Guys....

Limits are COntrollers and Handling, stability, and reliability of those Bikes. Saving probably 7kg or more, and mostly from the unsprung mass on the wheel, A mid-drive single stage setup with a motor like the RV could make sense for a Proper FS offroad bike Based on DH standards (well not for the speed at 100V

).

Otherwise, A Full suspension DH or MTB with such a second bike weight centered on the wheel (cromotors and similars) Would be simply, only, the best donor Bicycle in terms of strength, travel, forks and brakes for that crazy heavy and torquey motors, but not a well suited vehicle for that motor in absolute terms....at all, that's my feel.

Just my 1000 cents