DrkAngel

1 GW

Vetting the XYD-16 24V 450w DC Brush Motor

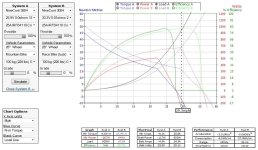

While hunting for a replacement, I found the manufactures specs of this motor.

View attachment 1

Most surprising was that this 450w "rated" motor is capable of 750w output!

No, not by over volting, simply by removing the current limitation.

Rated 450w with a 26A controller.

70A controller allows 750w output.

Why the 450w rating ... ?

Regulated to prevent damaging heat!

But also, it places maximum motor output right near top speed ... where it is needed, for continuous cruising.

Hunting with the ebike.ca /simulator, I found a motor that matches the XYD-16 motor, at 24V with 13T motor sprocket mod, nearly identically.

The Nine Continents 3004

Proven out by comparing to 25A controller

Much easier to do a direct comparison

At 20mph+, torque, acceleration, efficiency etc. are nearly identical.

Motor is designed for cruising = ideal commuter.

Not ideal for hills, stop and go traffic etc.

You could regear to match your hills ... ?

But I recommend as more of a cruiser than a climber.

Of course ... with pedal assist at lower speeds, performance can be surprisingly good!

Manufactures specs in PDF

http://www.cytron.com.my/usr_attachment/XYD-16 Drawings.pdf

http://donar.messe.de/exhibitor/hannovermesse/2014/M619072/xyd-16-series-eng-296356.pdf

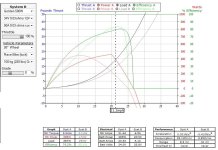

While hunting for a replacement, I found the manufactures specs of this motor.

View attachment 1

Most surprising was that this 450w "rated" motor is capable of 750w output!

No, not by over volting, simply by removing the current limitation.

Rated 450w with a 26A controller.

70A controller allows 750w output.

Why the 450w rating ... ?

Regulated to prevent damaging heat!

But also, it places maximum motor output right near top speed ... where it is needed, for continuous cruising.

Hunting with the ebike.ca /simulator, I found a motor that matches the XYD-16 motor, at 24V with 13T motor sprocket mod, nearly identically.

The Nine Continents 3004

Proven out by comparing to 25A controller

Much easier to do a direct comparison

At 20mph+, torque, acceleration, efficiency etc. are nearly identical.

Motor is designed for cruising = ideal commuter.

Not ideal for hills, stop and go traffic etc.

You could regear to match your hills ... ?

But I recommend as more of a cruiser than a climber.

Of course ... with pedal assist at lower speeds, performance can be surprisingly good!

Manufactures specs in PDF

http://www.cytron.com.my/usr_attachment/XYD-16 Drawings.pdf

http://donar.messe.de/exhibitor/hannovermesse/2014/M619072/xyd-16-series-eng-296356.pdf