The idea is not yet complete, but I was inspired to at least start physically putting stuff together after many weeks of trying to figure out what to do, when I knocked over a bunch of stuff in the back room trying to get the dogs out of there (they were playing around and not helping much...).

Anyhow, in picking it up and putting it away in a better order, I realized a few things that would fit together, starting with the Schwinn Sierra and Trek 930 frames I had gotten in the roadside find a few weeks back, I guess it was, plus a couple of rackmount cabinet rails.

Structural:

Basically, the rear wheel comes out of the Schwinn frame and goes into the rear triangle of the Trek frame. The Trek's headtube gets clamped to the seattube of the Schwinn, a bit above midway between stays. The rack rails screw into the accessory screwmounts on each triangle's dropouts, tying them together fairly stiffly (pretty much the same way I did it on CrazyBike2). Interestingly enough, not only do rackmount screws fit bike accessory mounts, the spacing between the mounts happens to line up perfectly with the rack screw holes, so I don't even have to drill new holes in them.

I will have to drill out some holes in the rails to clear a few things, and cut them to clear the cranks and whatnot; most likely I will cut just one rail in half and use it for both sides--it should be long enough to give me all the frame support and cargo pod mounting points I need.

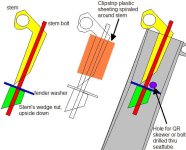

Hose clamps will not be sufficient for on-road operations, so I will end up using U-bolts most likely, to hold the headtube and seattube together. I may drill a hole in the toptube of the Trek lined up with the cross-bar of the Schwinn's seatstays to bolt them together there, too.

Theoretically it might be better to take the bearing races out of and cut the headtube of the Trek in half vertically, so I can clamp it around the seattube intead of just clamping up against it's backside. Doing that will change the positions of the dropout accessory points, so they might then require drilling holes in the rack rails. Oh well.

Seat:

The seat in the pictures is not what will be used, but it proved to me I can reach the pedals and can sit comfortably on it, reaching the handlebars in the seattube of the Schwinn, and that my knees will clear everything ok.

Steering:

For steering, the rear bars will be connected to the front by a tie rod (probably using skate bearings) just like i did for CrazyBike2, but this configuration will look more like Justin's cross-Canada bike's steering. I'll most likely leave the bars on there as mounting points for things like lights.

Motor:

Motor power will likely be provided by the Fusin front hubmotor, until I can come up with something more powerful to drive it thru the regular chain system, similar to CrazyBike2.

Drivetrain:

One difference is that I've got a rear hub and cassette in the Schwinn's dropouts, so I don't end up with either a long chainline, or a left-side pedal setup, and this means I can keep the pedal three chainrings shiftable, on the right.

There will be a chainring bolted to the hub itself on the righthand spoke flange, which is what the rear chain that goes to the rear wheel itself will mount to. The dropouts at the rear are barely big enough to hold a wheel at all, but the dropouts for the midhub are almost horizontal and can be used for chain length/tension adjustments if I use a single-speed setup at the rear.

I might leave the whole rear derailer and cassette on there, though, giving me even more gears if I need them for pedal-only helping using the front hubmotor, or gears specifically for the final motor/pedal drive stage once I add a motor into that drivetrain. Then I could put the motor input sprocket on the left spoke flange of the midhub, and that will give me a freewheel to keep pedals being driven by the motor (though it doesn't prevent pedalling from driving the motor).

A single speed would leave more symmetrical room at the rear, though, so I don't have to space out the rightside cargo pod/rail as I did on CrazyBike2 and would have to do on DayGlo Avenger if I ever put a rightside pod on it.

Suspension:

I will probably replace the front U-fork with a suspension fork, at least, after I change from hub to chain drive. Maybe before, if I use my steel fork off DGA or one of the others I have here is strong enough, or using torque arms if necessary.

More thoughts later, first some pics: