You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this Cromotor for real?

- Thread starter Boestin

- Start date

voicecoils

1 MW

Looks real to me.

I've seen several versions of the Cromotor doing wheelbuilds for people.

The hub is made in China, finished in Croatia as I understand.

The Chinese factory makes this size motor for scooters and the Cromotor company gets a version produced that is spec'd to suit bicycle brakes and gears. It's also spec'd for higher power with thin stator laminations, thick phase wires etc.

I've seen several versions of the Cromotor doing wheelbuilds for people.

The hub is made in China, finished in Croatia as I understand.

The Chinese factory makes this size motor for scooters and the Cromotor company gets a version produced that is spec'd to suit bicycle brakes and gears. It's also spec'd for higher power with thin stator laminations, thick phase wires etc.

The Cromotor guys market their website from their home in Croatia. You can get whatever you want from China, just pay up front and order 100 units. They took a bold risk and correctly discerned that there was a market for a scooter motor with the width and axle made to fit a bicycle frame. The second version (V2) had thinner lams ( and thicker phase wires, plus temp sensor) to help efficiency and lower motor heat per amps applied (effectively raising the amount of peak and continuous amps possible without overheating).

However...it has always been manufactured in China. They will even engrave "manufactured in our state of the art factory on the moon" onto the sideplates if that's what you pay for. Here's a brain-twister for you...the same exact factory that makes the Cro, might also be making the counterfeits. Looks exactly like like a Cro on the outside, but cheaper insides. The real question for you: is this a good motor?

Take it apart and count the laminations, divide by the width of the stator to determine if it has the common 0.50mm lams, or the thinner 0.35mm lams, measure the diameter of a bare section of phase wire copper, look for a temp sensor inside...

However...it has always been manufactured in China. They will even engrave "manufactured in our state of the art factory on the moon" onto the sideplates if that's what you pay for. Here's a brain-twister for you...the same exact factory that makes the Cro, might also be making the counterfeits. Looks exactly like like a Cro on the outside, but cheaper insides. The real question for you: is this a good motor?

Take it apart and count the laminations, divide by the width of the stator to determine if it has the common 0.50mm lams, or the thinner 0.35mm lams, measure the diameter of a bare section of phase wire copper, look for a temp sensor inside...

Boestin

100 W

Thanks for the information!

I don't want to take it apart (yet ) cause the lack of proper tools around here. Visually it looks like a genuine one except for the isolation around the wires.

) cause the lack of proper tools around here. Visually it looks like a genuine one except for the isolation around the wires.

Almost every cromotor has a cotton-like isolation, with a whitish end when entering the hub.. I'll look those pictures up in a sec and compare it with the plastic-like on mine.

I don't want to take it apart (yet

Almost every cromotor has a cotton-like isolation, with a whitish end when entering the hub.. I'll look those pictures up in a sec and compare it with the plastic-like on mine.

Boestin

100 W

The hub is doing strange, I am getting Halls errors on the Adaptto. I think I have cut some hallwires.

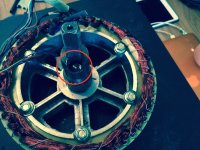

So.. I decided to open up the "Cromotor" and took some pictures while I was at it.

So.. I decided to open up the "Cromotor" and took some pictures while I was at it.

Attachments

Boestin

100 W

I removed the bearings, which I'm going to replace with better quality. The thickness of the lamination is 0,36mm, so that seems to be OK.

All wires seem to be in order, no isolation defect or what so ever.. How can I measure the windings? Oh and I cut myself trying to get the hall sensor out, any tips how to get that out?

Thanks..

Below some pictures for general interest:

All wires seem to be in order, no isolation defect or what so ever.. How can I measure the windings? Oh and I cut myself trying to get the hall sensor out, any tips how to get that out?

Thanks..

Below some pictures for general interest:

Attachments

zombiess

10 MW

Looks like the same core as a Cromotor, but the axle is all wrong. Ergo it is not a Cromotor.

Why are you tearing it apart if there is nothing wrong? Doesn't seem worth while to rip out the hall sensors. I don't think I've ever removed one without complete destroying it and then having to clean out the mess with a tiny screw drivers. Not exactly a fun job.

Why are you tearing it apart if there is nothing wrong? Doesn't seem worth while to rip out the hall sensors. I don't think I've ever removed one without complete destroying it and then having to clean out the mess with a tiny screw drivers. Not exactly a fun job.

Boestin

100 W

zombiess said:Looks like the same core as a Cromotor, but the axle is all wrong. Ergo it is not a Cromotor.

Why are you tearing it apart if there is nothing wrong? Doesn't seem worth while to rip out the hall sensors. I don't think I've ever removed one without complete destroying it and then having to clean out the mess with a tiny screw drivers. Not exactly a fun job.

Hi zombiess!

Well I got halls errors and the motor stuttered.. I thought there was a shortcut somewhere or maybe some wires/hall sensors damaged. I think 1 sensor is broken, but it doesn't explain the other one failing. So my plan is to upgrade the phase wires to 10awg and put 2 sets of Honeywell ss41 in there. That's basically the plan for now. :?

Could it be that the windings have some damage? Can I measure this?

Boestin

100 W

Holidaytime I guess..

Voltron

1 MW

An easy winding test is to short two of the phases together.. the motor should be really hard to spin suddenly as one phase winding fights the other. Then repeat until the three combos have been tried.

edit.. just realized that might not be so easy with the one cover off....

edit.. just realized that might not be so easy with the one cover off....

Boestin

100 W

I upgraded the phase wires to awg10 and put new hallwires in there. I broke one set of hall sensors, so I didn't bother to wire them up.

When I put it all together, there is still a hall malfunction. So there is one hall sensor that is broken for sure, because the wires are ok. In the Adaptto display there are 3 numbers which have to go from 0 to 1 and back again, each of them. The last number sticks on 1. So thats broken, have to replace that.

Meanwhile I have encountered another problem. I hope someone here on this forum can help me out. When I run sensorless on the Adaptto it runs. But only for 30% of the power. If I accelerate harder then the motor start cogging. I don't know if that is the right word for it, maybe stuttering. The speed is not the problem, I can easy go to about 75kph.

What could it be?

Is this Adaptto behaviour? (hence I am crossposting this issue on the Adaptto thread)

Edit: Adaptto behaviour confirmed.

When I put it all together, there is still a hall malfunction. So there is one hall sensor that is broken for sure, because the wires are ok. In the Adaptto display there are 3 numbers which have to go from 0 to 1 and back again, each of them. The last number sticks on 1. So thats broken, have to replace that.

Meanwhile I have encountered another problem. I hope someone here on this forum can help me out. When I run sensorless on the Adaptto it runs. But only for 30% of the power. If I accelerate harder then the motor start cogging. I don't know if that is the right word for it, maybe stuttering. The speed is not the problem, I can easy go to about 75kph.

What could it be?

Is this Adaptto behaviour? (hence I am crossposting this issue on the Adaptto thread)

Edit: Adaptto behaviour confirmed.

Boestin

100 W

The cogging from the motor lies with the controller, since it is intented to run with sensors... Guess I have to pince out the halls now

kiwiev

100 kW

Boestin

100 W

Sorry mate for replying so late.

The transparent wire is for the temp.

The transparent wire is for the temp.

kiwiev

100 kW

No worries mate all goodBoestin said:Sorry mate for replying so late.

The transparent wire is for the temp.

Cheers Kiwi

Boestin

100 W

1 hall sensor was not working so I decided to replace them all with Honeywell SS41 halls. Result: what a monster! 16,5KW with a stock adaptto max!!

Attachments

kiwiev

100 kW

Nice build what's the frame?

Cheers Kiwi

Cheers Kiwi

Due to the way the axle is cut, I now believe this is a QS motor, very similar to Cro, but I believe it is a little better.

https://www.electricbike.com/large-hot-rod-hubmotors

https://www.electricbike.com/large-hot-rod-hubmotors

DasDouble

100 kW

Dude haha  You hav two wire cables. So if on is not working correct just plug in the whole thing into the other one. Should work

You hav two wire cables. So if on is not working correct just plug in the whole thing into the other one. Should work  But hey, what a nice bike and what nice streetrace tires!

But hey, what a nice bike and what nice streetrace tires!

Accountant

10 W

Hello,

This is not a Cromotor.

Original Cromotors are designed in Croatia. Some parts are manufactured in China and some are manufactured in Croatia.

Assembly and quality control are done in Croatia.

Nope QS motors are not better than original Cromotor.

You can buy Cromotors here =

www.zelenavozila.com

This is not a Cromotor.

Original Cromotors are designed in Croatia. Some parts are manufactured in China and some are manufactured in Croatia.

Assembly and quality control are done in Croatia.

Nope QS motors are not better than original Cromotor.

You can buy Cromotors here =

www.zelenavozila.com

ridethelightning

1 MW

- Joined

- Jul 21, 2013

- Messages

- 2,010

subscribe

ridethelightning

1 MW

- Joined

- Jul 21, 2013

- Messages

- 2,010

Accountant said:Hello,

This is not a Cromotor.

Original Cromotors are designed in Croatia. Some parts are manufactured in China and some are manufactured in Croatia.

Assembly and quality control are done in Croatia.

Nope QS motors are not better than original Cromotor.

You can buy Cromotors here =

http://www.zelenavozila.com

As owner of several of both cromotor and qs205 v3, i would be very interested in any quantitative information to support this claim, as I am of course always looking for the best quality motor,as I beleive any warm blooded E.S. member would be, and would like to know any techniques to measure/compare their quality.

so far I know to look for:

1, thinner stator laminations

2,thicker phase conductors

3, silicone steel in the stator lams

4,quality/design of axle material

5,production quality(halls intallation etc.)

6,quality of magnets

7, quality of winding insulating varnish, resistance to temperature.

things i would like to learn more about are:

1, how number of stator tooth and number of magnets affects the motor performance.

2, how to measure quality of magnets

3, how to measure quality of stator steel with regard to silicone content

regards

RTL

ridethelightning

1 MW

- Joined

- Jul 21, 2013

- Messages

- 2,010

Boestin said:Hi guys,

How can I tell this Cromotor is real? I bought this from a endless-sphere user and I see chinese marks on the box. The true Cro comes from Slovinia or Russia I believe?

Thanks.

id say its actually not a QS or cromotor, but one of these-

http://www.enduroebike.com/sale-6123529-190n-m-850rpm-single-speed-electric-motorcycle-hub-motor-70-120km-h.html

they use those rhino lite rims as stock also..very nice motors also id say.

Similar threads

- Replies

- 8

- Views

- 372

- Replies

- 0

- Views

- 111

- Replies

- 29

- Views

- 1,536

- Replies

- 2

- Views

- 257