Hello all -

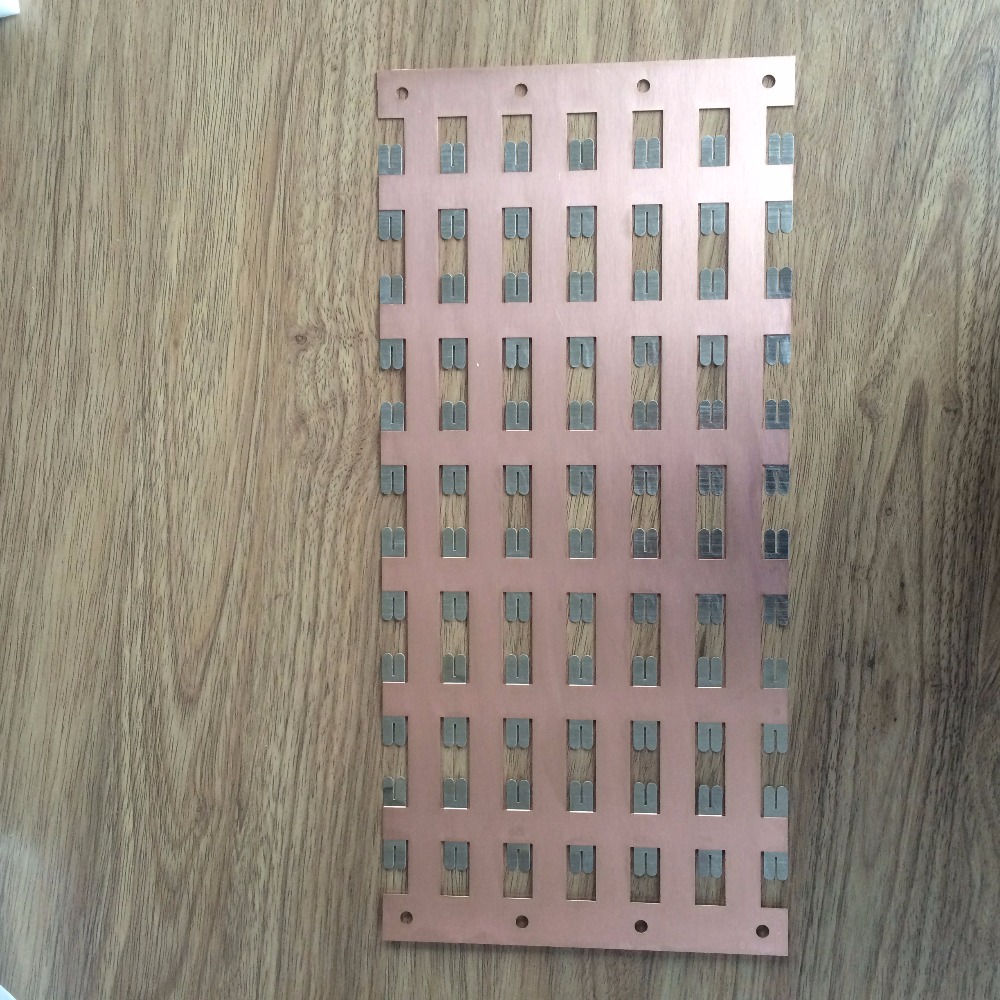

I’m having trouble connecting my 24 LifePo4 cells in Series. These are 3.2v, 50ah. Now, the terminals do not have screws/holes for me to connect nickel or copper plates for connecting purposes. Therefore I must solder or spot weld these (assuming no other options). Since my controller is drawing 100a continuous, I need a piece of nickel or copper that contains enough volume to allow my batteries to discharge with the least amount of resistance. The nickel strips for 18650’s seem to be not enough. Anything larger however, whether a big piece of nickel or even copper, I feel spot welding will damage my cells potentially. I understand soldering isn’t ideal due to the duration of the heat supplied on the pad. What do you guys do in situations like this?

Thanks,

Joe

I’m having trouble connecting my 24 LifePo4 cells in Series. These are 3.2v, 50ah. Now, the terminals do not have screws/holes for me to connect nickel or copper plates for connecting purposes. Therefore I must solder or spot weld these (assuming no other options). Since my controller is drawing 100a continuous, I need a piece of nickel or copper that contains enough volume to allow my batteries to discharge with the least amount of resistance. The nickel strips for 18650’s seem to be not enough. Anything larger however, whether a big piece of nickel or even copper, I feel spot welding will damage my cells potentially. I understand soldering isn’t ideal due to the duration of the heat supplied on the pad. What do you guys do in situations like this?

Thanks,

Joe