thunderheart

100 W

Original article: https://www.thunderheartreviews.com/2019/08/samsung-29e-version-7-29e7-2900mah-review.html

Less than a month ago i tested Samsung 29E v.6 which many people say is a better cell than the v.7. This time i've tested the v.7 cell and compared them to find out where is the truth. Just to remind, Samsung 29E is a 2900mAh 18650-size cell which supports discharge at up to 5.5A.

The battery was bought from my reliable supplier (Queen Battery) and tested with ZKETECH EBC-A20 and a self-made battery holder. It's a PC-connected battery tester supporting 4-wire measuring and discharging at up to 20A.

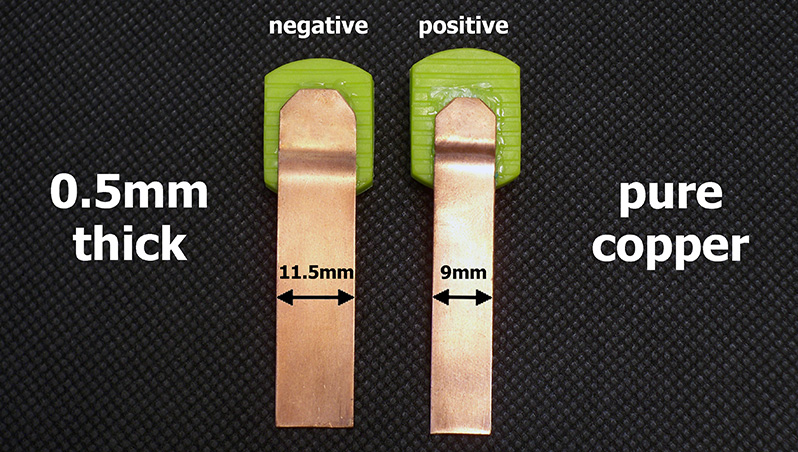

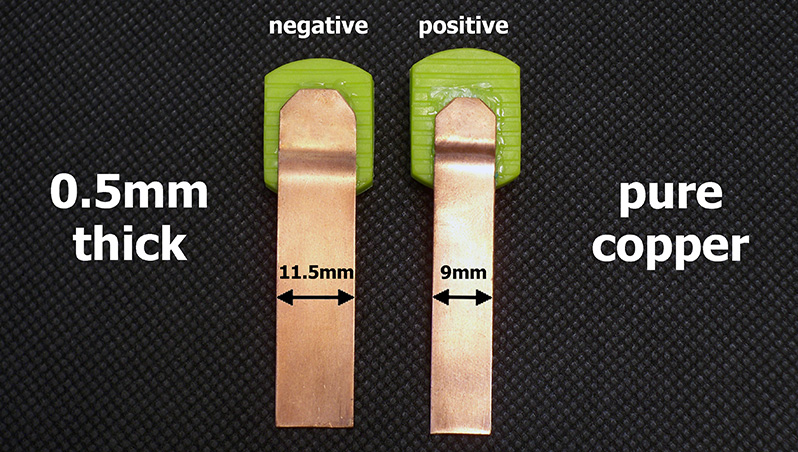

I've used version 3.0 of my battery holder based on 0.5mm thick pure copper terminals

I've followed all the prescriptions of the IEC61960-2003 standard concerning battery's capacity measurement. Before each discharging cycle each battery was charged at standard charge current mentioned in its datasheet to charge end voltage. Before each discharging or charging i've held a 1-1.5hrs pause. The environment temperature was 25±2°C. To be sure in results i've done each test minimum twice (usually 3-7 times).

Samsung INR18650-29E v.7

The cell is marked as INR18650-29E SAMSUNG SDI 7 HJ4T - number 7 stands for the version. This cell has also a 2D barcode on its back which has this code BRHA9E7Q50508297H7TT143509210000000000000 encoded.

The main specs from Samsung 29E datasheet:

Typical capacity: 2850mAh

Minimum capacity: 2750mAh

Nominal voltage: 3.65V

Standard charge current: 1.375A (0.5C)

Maximum charge current: 2.75A (1C)

Charge cut-off current: 55mA (0.02C) (100mA used)

Charge end voltage: 4.20V

Max. continuous discharge current: 5.5A (2C)

Discharge cut-off voltage: 2.5V

AC impedance at 1KHz: ≤35 (45) mΩ

Max weight: 48g

Cycle life:

Using 1.375A (0.5C) charge with 137.5mA (0.05C) cut-off and 2.75A (1C) discharge with 2.5V cut-off after 500 cycles the capacity should be ≥1868mAh (70% of rated capacity).

DC IR at 2.75A in fully charged condition was 26±1.6mΩ (measured using EB Tester Software's Resistance test feature).

Measured dimensions: 18.2mm (diameter) × 64.9mm (length).

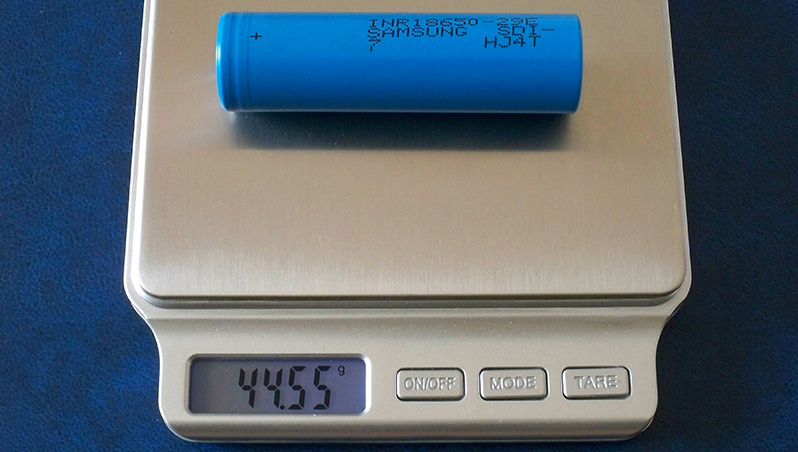

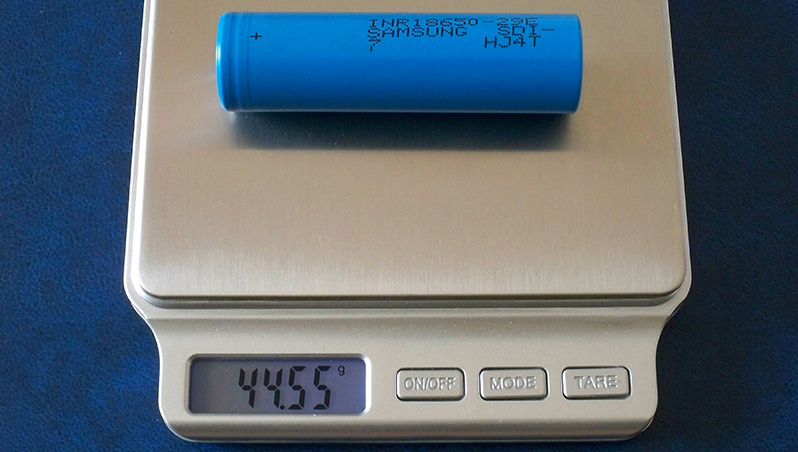

Measured weight: 44.55g.

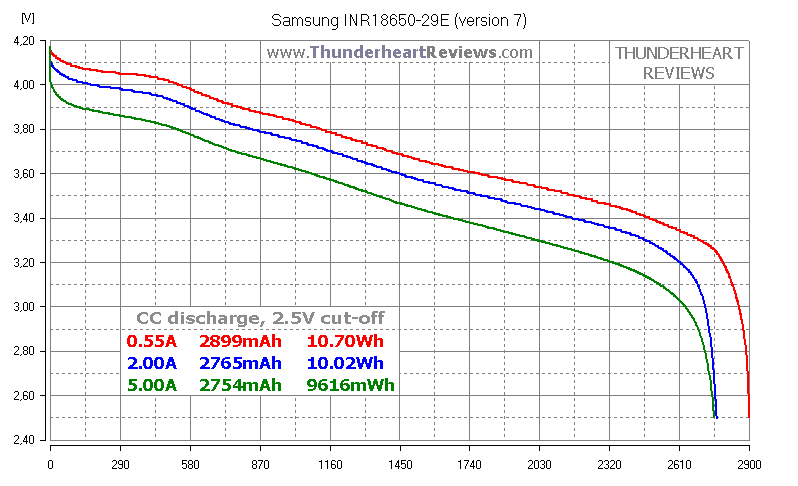

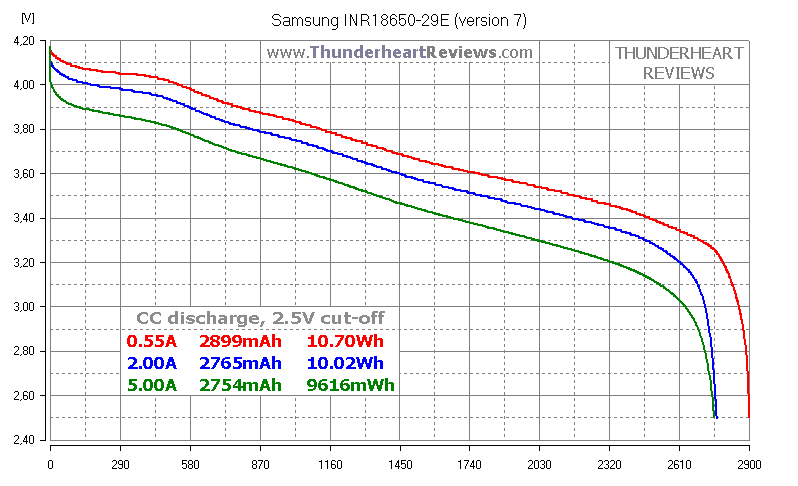

Samsung 29E version 7 capacity test results:

First i need to mention the beauty of curves and that they are as linear as possible! Even the 5A curve! The results are much like those of v.6 but a bit better, so let's compare them step by step.

Comparison

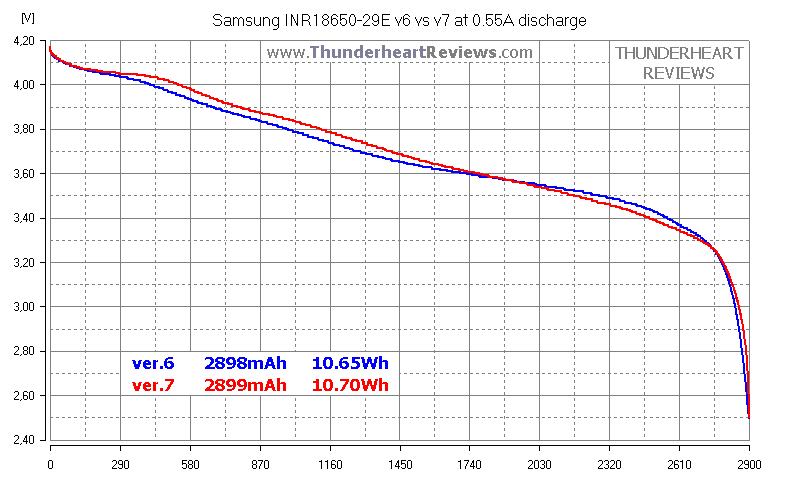

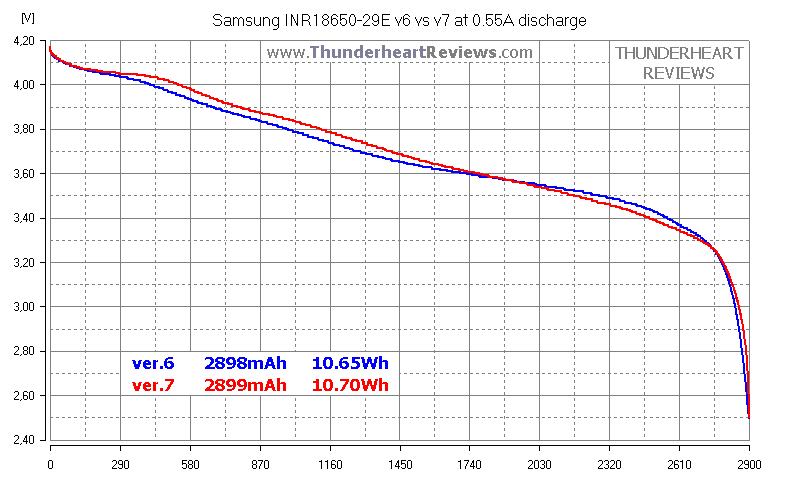

At 0.2C/0.55A discharge:

Only 1mAh difference in capacity and 0.05Wh in energy!!! But the curves are what's important - 29E7 curve looks more linear than that of 29E6 though they are very close.

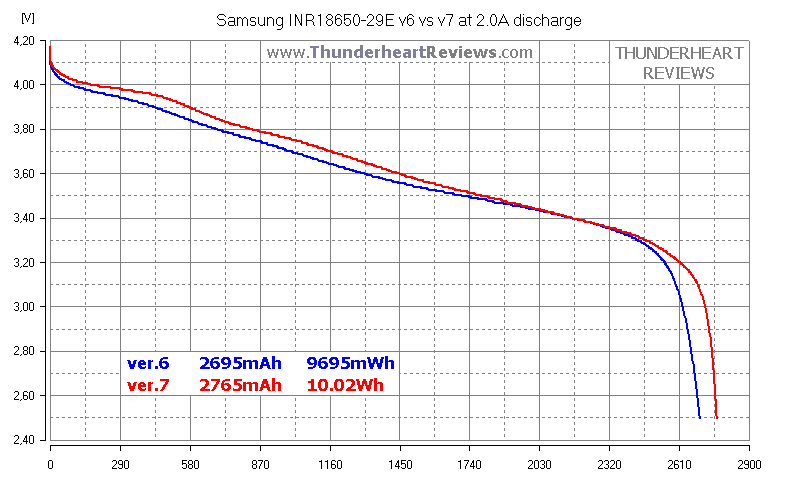

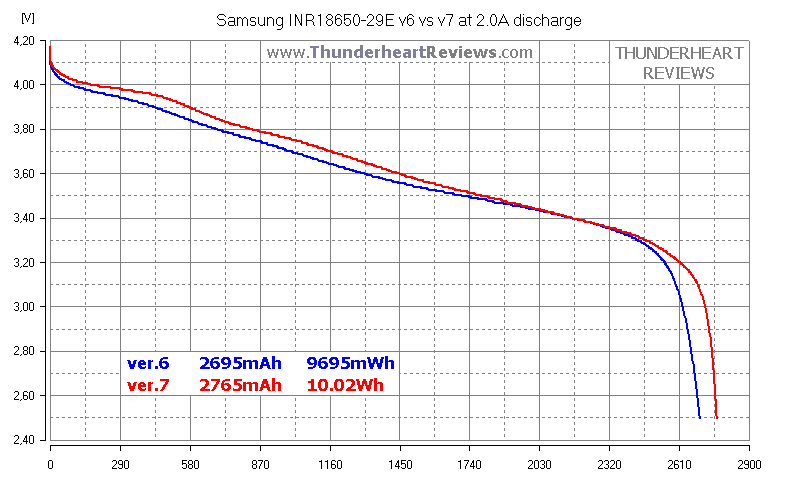

At 2A discharge:

The difference stars to rise and 29E7 shows 70mAh higher capacity and 325mWh in energy. Again, 29E6 curve doesn't look as linear as 29E7's.

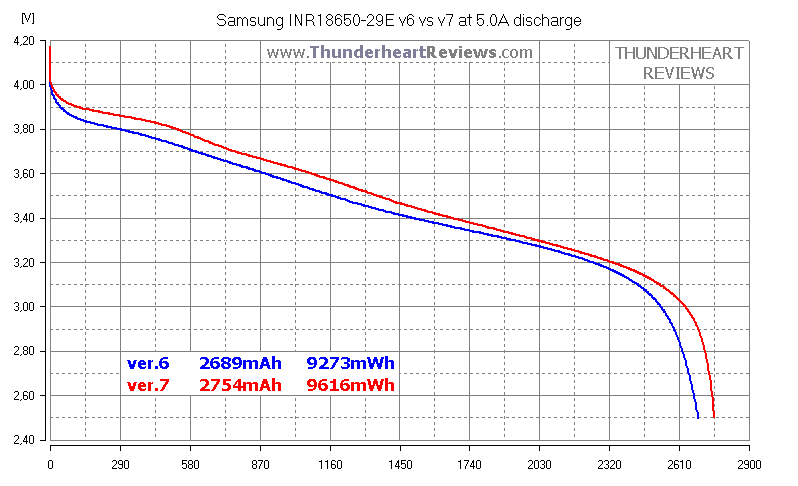

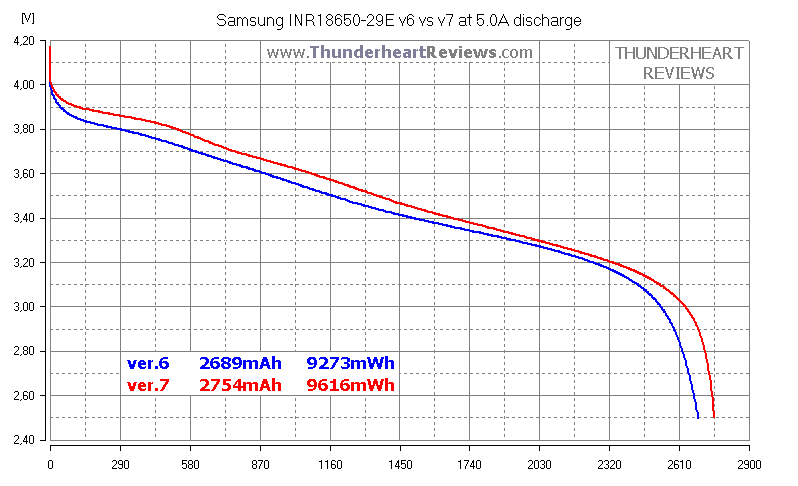

At 5A discharge:

29E7 proves that it's the better cell. 65mAh in capacity and 343mWh in energy is not a huge difference but it exists. Both curves look good and it's not easy to tell which one is better...

Verdict

So, there was no big leap ahead but it's clear that Samsung 29E7 is a better cell than 29E6. Version 6 has slightly lower capacity and energy and nice curves, but version 7 has even nicer ones, almost ideal i'd say. If i had to choose between two versions i'd take v.7 of course.

Here is the video version of this review:

Check out my YouTube channel for batteries, chargers and other stuff reviews.

I've launched my blog where you can find all my reviews in one place. Every new test/review will be first published on YouTube and in the blog. I'll be happy to see new subscribers, comments, suggestions and just your thoughts.

Less than a month ago i tested Samsung 29E v.6 which many people say is a better cell than the v.7. This time i've tested the v.7 cell and compared them to find out where is the truth. Just to remind, Samsung 29E is a 2900mAh 18650-size cell which supports discharge at up to 5.5A.

The battery was bought from my reliable supplier (Queen Battery) and tested with ZKETECH EBC-A20 and a self-made battery holder. It's a PC-connected battery tester supporting 4-wire measuring and discharging at up to 20A.

I've used version 3.0 of my battery holder based on 0.5mm thick pure copper terminals

I've followed all the prescriptions of the IEC61960-2003 standard concerning battery's capacity measurement. Before each discharging cycle each battery was charged at standard charge current mentioned in its datasheet to charge end voltage. Before each discharging or charging i've held a 1-1.5hrs pause. The environment temperature was 25±2°C. To be sure in results i've done each test minimum twice (usually 3-7 times).

Samsung INR18650-29E v.7

The cell is marked as INR18650-29E SAMSUNG SDI 7 HJ4T - number 7 stands for the version. This cell has also a 2D barcode on its back which has this code BRHA9E7Q50508297H7TT143509210000000000000 encoded.

The main specs from Samsung 29E datasheet:

Typical capacity: 2850mAh

Minimum capacity: 2750mAh

Nominal voltage: 3.65V

Standard charge current: 1.375A (0.5C)

Maximum charge current: 2.75A (1C)

Charge cut-off current: 55mA (0.02C) (100mA used)

Charge end voltage: 4.20V

Max. continuous discharge current: 5.5A (2C)

Discharge cut-off voltage: 2.5V

AC impedance at 1KHz: ≤35 (45) mΩ

Max weight: 48g

Cycle life:

Using 1.375A (0.5C) charge with 137.5mA (0.05C) cut-off and 2.75A (1C) discharge with 2.5V cut-off after 500 cycles the capacity should be ≥1868mAh (70% of rated capacity).

DC IR at 2.75A in fully charged condition was 26±1.6mΩ (measured using EB Tester Software's Resistance test feature).

Measured dimensions: 18.2mm (diameter) × 64.9mm (length).

Measured weight: 44.55g.

Samsung 29E version 7 capacity test results:

First i need to mention the beauty of curves and that they are as linear as possible! Even the 5A curve! The results are much like those of v.6 but a bit better, so let's compare them step by step.

Comparison

At 0.2C/0.55A discharge:

Only 1mAh difference in capacity and 0.05Wh in energy!!! But the curves are what's important - 29E7 curve looks more linear than that of 29E6 though they are very close.

At 2A discharge:

The difference stars to rise and 29E7 shows 70mAh higher capacity and 325mWh in energy. Again, 29E6 curve doesn't look as linear as 29E7's.

At 5A discharge:

29E7 proves that it's the better cell. 65mAh in capacity and 343mWh in energy is not a huge difference but it exists. Both curves look good and it's not easy to tell which one is better...

Verdict

So, there was no big leap ahead but it's clear that Samsung 29E7 is a better cell than 29E6. Version 6 has slightly lower capacity and energy and nice curves, but version 7 has even nicer ones, almost ideal i'd say. If i had to choose between two versions i'd take v.7 of course.

Here is the video version of this review:

Check out my YouTube channel for batteries, chargers and other stuff reviews.

I've launched my blog where you can find all my reviews in one place. Every new test/review will be first published on YouTube and in the blog. I'll be happy to see new subscribers, comments, suggestions and just your thoughts.