Hey all,

Planning on building a battery pack for trolling motor, I will be using LG hg2 chem.

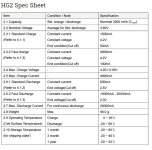

Battery model: LG HG2

Build: 7S15P or 3*7s5p

I would like to break the pack to 3 small packs to allow for fast charging, I would rather have a 3 charger to charge 7s5P instead of charging 7s15P it will take forever 45amp

Thinking of having 3 BMS for each pack separately and then connect the packs in parallel.

Would this be double without separating the pack every time I need to charge the 3 packs, my question can I attach the 3*7s5p together and have a break point in between when I charge them?

Is what Im thinking is crazy? Or double.

Sorry I’m not that guru but been building small packs of 3s for fish finder, and they work like a charm.

Many thanks

Planning on building a battery pack for trolling motor, I will be using LG hg2 chem.

Battery model: LG HG2

Build: 7S15P or 3*7s5p

I would like to break the pack to 3 small packs to allow for fast charging, I would rather have a 3 charger to charge 7s5P instead of charging 7s15P it will take forever 45amp

Thinking of having 3 BMS for each pack separately and then connect the packs in parallel.

Would this be double without separating the pack every time I need to charge the 3 packs, my question can I attach the 3*7s5p together and have a break point in between when I charge them?

Is what Im thinking is crazy? Or double.

Sorry I’m not that guru but been building small packs of 3s for fish finder, and they work like a charm.

Many thanks