SpeedRacer93 said:

I have been working on a project and we are looking for cells that we need a high C rate.

The electric motor will be running for about 90 second but be at full load (ie 1000 AMPS). Current pack design is 400 Volt 109S4P of 5 Ah pouch cells. We are still working on motor/controller development so the end voltage is not set yet.

Weight is a concern so the lighter the better.

Using a RC pack of 50C or 100C would be an option but the power leads are a limiting factor. We are looking for bare cells. Opposite end tabs would be the best for packaging and buss bar connections.

Yes I am aware of the LoneStar Sleeper Cells which is at the top of the list but looking for other sources.

I have heard YGS Lipo talked about but I unable to fine info about them. Looks like the web site is down/coming soon.

I know battery companies/suppliers come and go but looking for leads that we may be able to use once the world settles down.

Thanks!!

I haven't used these guys, but I have heard good things about them, and they have been around for a while. I looked at their products a while back when designing an electric motorcycle, but decided upon a different chemistry (LTO):

http://www.herewin.com/en/index.asp

Shenzhen Herewin Battery. There was talk on an RC forum that they are actually the parent company for one or more of the most common mid-range RC batteries out there. Might have been Turnigy? So they aren't going to be best on market, but you won't be paying best on market price either.

They do make cells with tabs on opposing sides, but from my experience, that only starts when you start hitting 20Ah size and above, so you might not get exactly what you need.

I hope you excuse me if you see this as rude... But I'm seeing an odd dichotomy here. Nobody takes a project of this challenge on without a shit tonne of knowledge behind them, so I reckon you're pretty cluey about all this stuff. But even as an amateur, a few things stick out to me:

1. 1000A for 90 seconds = 1000/3600 x 90 = 25Ah. 4P of 5Ah packs = 20Ah. Whatever you're building is going to be cruising on momentum for the last 18 seconds or so...

2. Draining a battery from full to flat is a not only a good way to make sure you only get a few cycles out of them, you're going to get an inconsistent speed as the internal resistance changes at the top and bottom of the pack.

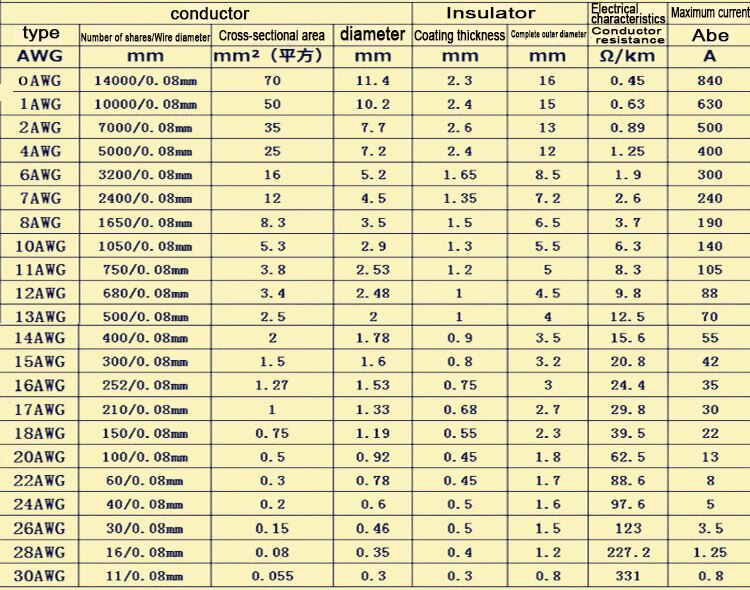

3. If the power leads are the only thing stopping you from using RC Lipo... What's stopping you from putting your own power leads on them? One thing to remember is that Ampacity tables are assuming long runs (i.e. some of the cable will have nothing to sink heat into except the insulation) and indefinite time frames (I.e. will eventually reach thermal equilibrium above the rated temp of your insulation).

In your case, extremely short runs could use bus bars or other large metal bits as de-facto heat sinks, and after 90 seconds, if you're not yet at thermal equilibrium, it doesn't matter if you were over spec because you're not getting any hotter. Add to this some silicone insulation at 200*C instead of PVC, and while it might be hotter than you'd like, it's not hot enough to damage anything.

I'm not saying leave the standard 12AWG leads with XT90s on there (I've never understood how they can sell a battery capable of 250A, with wires capable of 88A, and a connector capable of 90A... But hey, I've seen worse come out of China), but 6 AWG will withstand 300A, Put some oversized copper bus bars at each end to sink some heat, and maybe a duplicated 0 awg run to the controller, keep the runs as short as you physically can and introduce some cooling from wind, and I think you'd be pretty safe.

We're all enthusiasts here, so would you mind sharing more about your project? Advice might also be able to be more tailored.