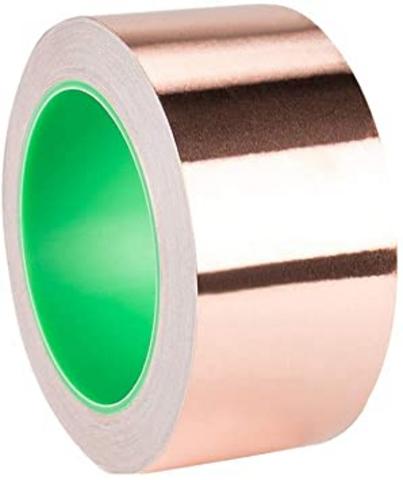

I tried the adhesive backed copper tape and it’s very bad at conducting through the adhesive. Welding it it explodes.

This will be far from a stationary battery. It’s designed to flex on a relatively stiff longboard. In my mind when it sits in the box on bottom of the board, cells down with Velcro holding the cells, and that’s the only contact the battery has, just the Velcro to the cells..it’s good. I don’t know about the tape connections surviving this environment long term but the batteries I’ve made like this, welded, are still working.

If the resistance of the connections doesn’t increase in use, as I imagine they will, it would be great to see.

So far I haven’t got one of these cells to go to fire with a continuous short at least.

How many welds or weld spots is good? I use .2x8mm strip. I’ve never seen conductance tests of welds