Allex

100 MW

[this thread was split off from another thread where a poster described issues with their DIY spot-weld pack, pics revealed a few poorly-chosen amp-flow paths]

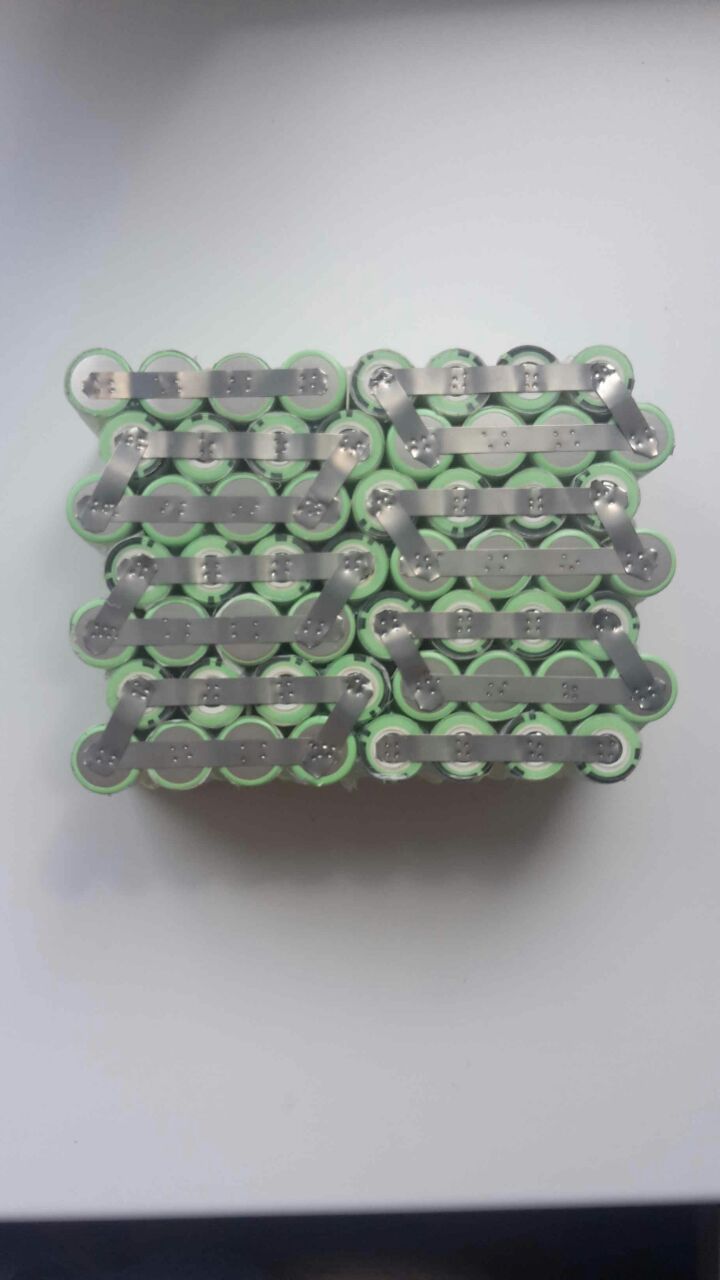

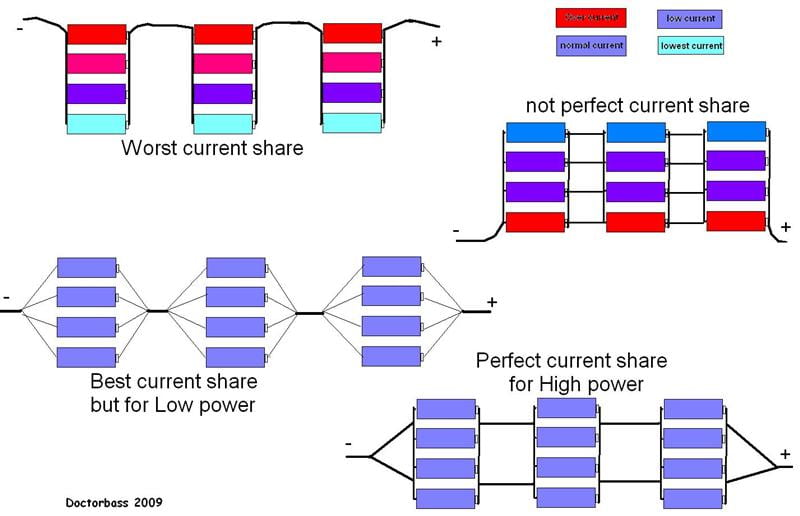

Boy, we should really have a thread on how to not build a battery. We have a great one on spot welding(https://endless-sphere.com/forums/viewtopic.php?f=14&t=68005) but we don't have Ultimate thread on how to actually design a pack so you can get the best current flow and avoid burned nickel, getting unnecessary voltage sag (unbalanced under load because of the wrong design) and dead cells as a result like in the below pictures. Everybody can build batteries but only 5% of the guys actually doing it right.

xxxxxxxxxxxxxxxx

moderator edit to add tip from this thread: hot-glued cells can be separated by using isopropyl alcohol on a cotton-tipped swab. https://endless-sphere.com/forums/viewtopic.php?f=14&t=84412&start=25#p1237470

also: nickel-plated copper bus bars are a good option to make the series connections between paralleled sub-packs. https://endless-sphere.com/forums/viewtopic.php?f=14&t=60364&start=25#p1235640

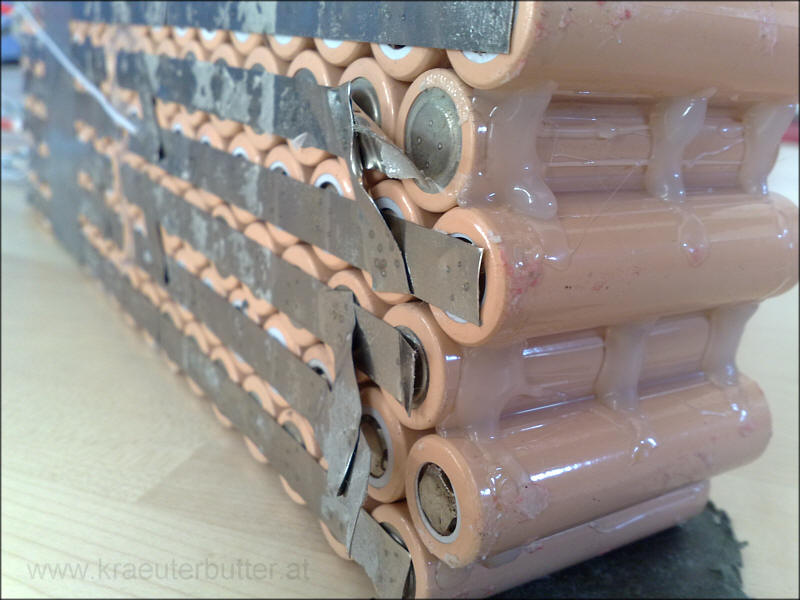

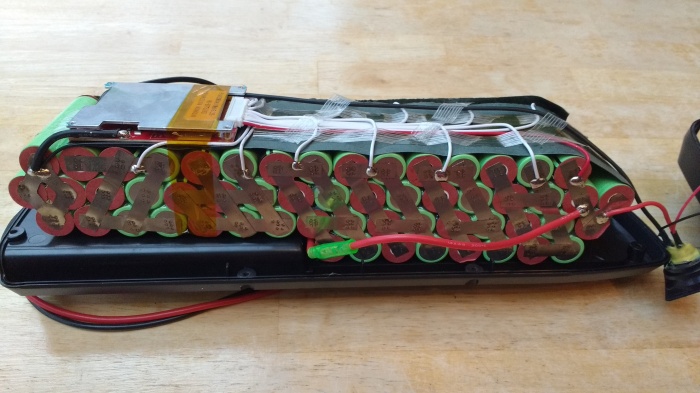

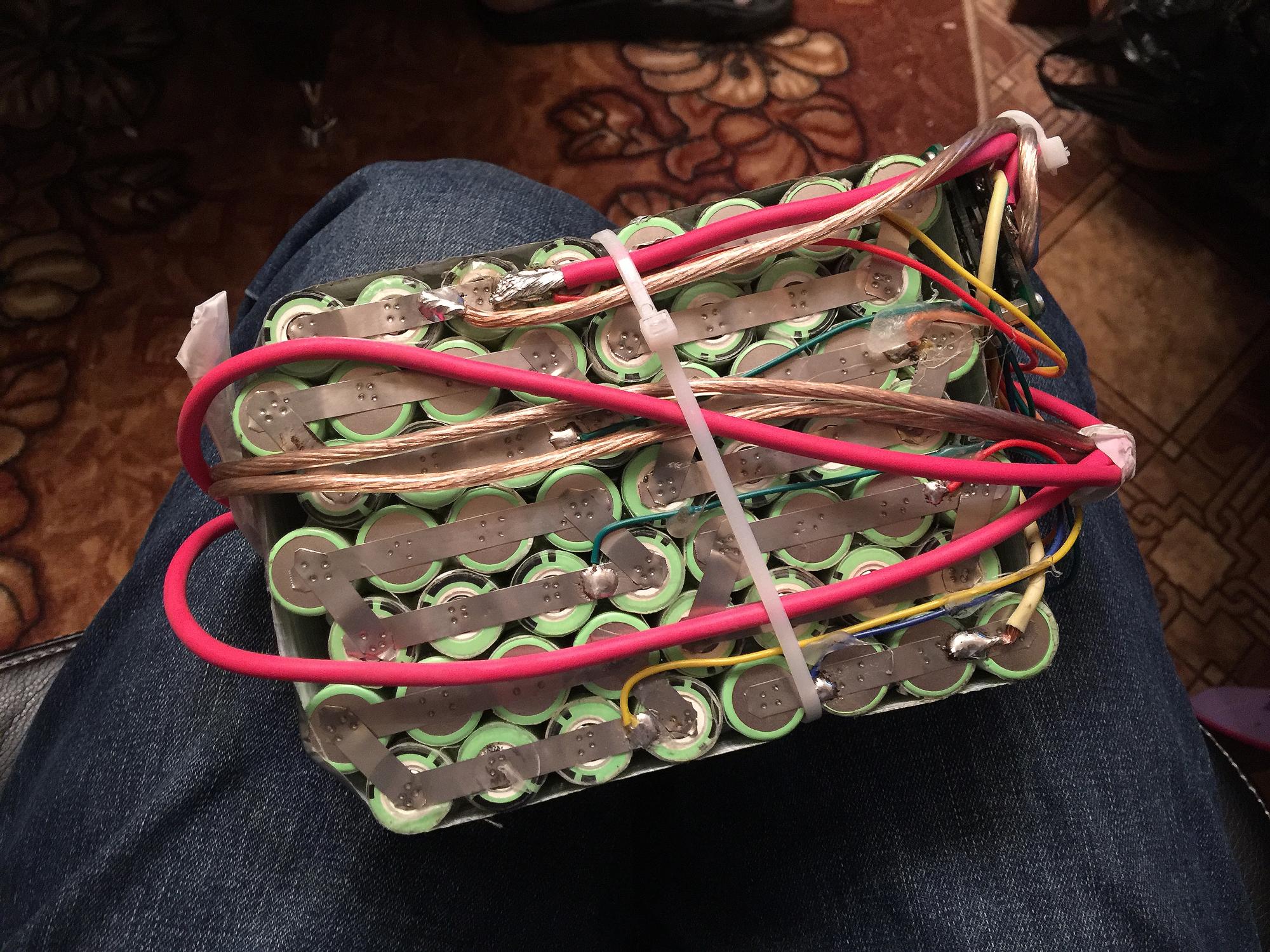

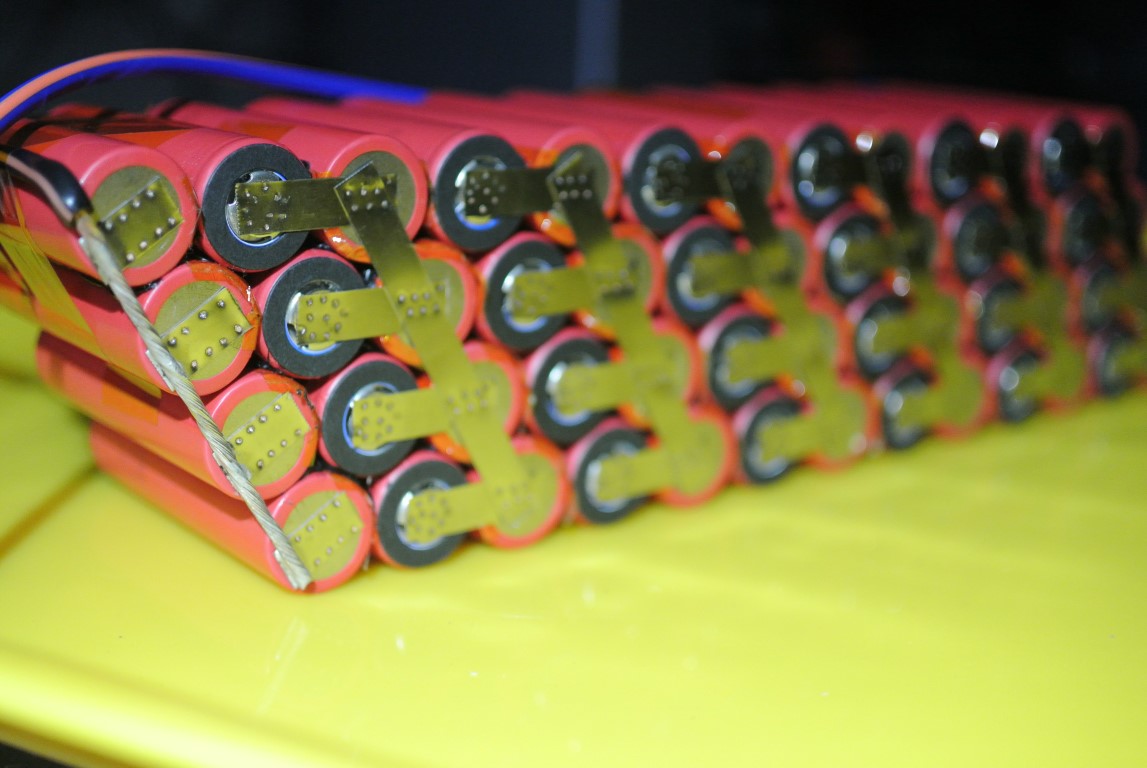

Here is an example of badly designed pack from china:

"The serial nickel conductors amount are not enough, but the main lead points are even worse.

Where the main battery wires are soldered, it that spots the nickel are completely in overcurrent. I don't see if they soldered more layers, in case that no, that points will heat the most in the battery, just check it."

Read more on why:

https://endless-sphere.com/forums/viewtopic.php?f=14&t=57291&start=550#p1034920

Boy, we should really have a thread on how to not build a battery. We have a great one on spot welding(https://endless-sphere.com/forums/viewtopic.php?f=14&t=68005) but we don't have Ultimate thread on how to actually design a pack so you can get the best current flow and avoid burned nickel, getting unnecessary voltage sag (unbalanced under load because of the wrong design) and dead cells as a result like in the below pictures. Everybody can build batteries but only 5% of the guys actually doing it right.

xxxxxxxxxxxxxxxx

moderator edit to add tip from this thread: hot-glued cells can be separated by using isopropyl alcohol on a cotton-tipped swab. https://endless-sphere.com/forums/viewtopic.php?f=14&t=84412&start=25#p1237470

also: nickel-plated copper bus bars are a good option to make the series connections between paralleled sub-packs. https://endless-sphere.com/forums/viewtopic.php?f=14&t=60364&start=25#p1235640

Here is an example of badly designed pack from china:

"The serial nickel conductors amount are not enough, but the main lead points are even worse.

Where the main battery wires are soldered, it that spots the nickel are completely in overcurrent. I don't see if they soldered more layers, in case that no, that points will heat the most in the battery, just check it."

Read more on why:

https://endless-sphere.com/forums/viewtopic.php?f=14&t=57291&start=550#p1034920