Hugh-Jassman

1 kW

- Joined

- Jun 20, 2015

- Messages

- 407

Continued from: Best motor and Voltage for large Cycletruck?

https://endless-sphere.com/forums/viewtopic.php?f=1&t=99337

I have an ammo box measured 11” x 6 3/4” x 5 5/8th inch inside leaving plenty room for the BMS on the top. 120 cells could fit into the box 10 x 6 x 2 = this will leave room between the 18650 cells for forced air from a pair of one inch thick fans. But maybe forcing air over the cells is not actually needed. I maybe could fit 132 cells without fans that I maynot need any how.

I am using a 52volt battery but the 13.5Ah [14s 4p = 56 cells 704watt hours] is half of what I really need. My motor sucks up to around 1800 watts on reasonably hard acceleration then drops back to around 1400 watts.

All I really need is more amp-hours. My worst hauling job yet was using an average of 53Wh per mile for about 500 total combined pounds over about 6.44 miles at 10.8 mph average. I usually use between 40 and 46Wh per mile over 9.6 to 11 miles round trip. At an average of 10.7 to 11.8 mph. And I do not use my legs; I developed severe arthritis in my knees by pedaling this kind of weight [400 to 500lbs] without a motor for way too many years.

I charge my battery to 80% the night before my trip to town, then up to 90% just before I leave about [45 minutes]. The last 10% takes too long.

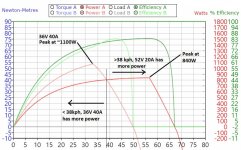

So how would this Cyclone3000 behave at a lower voltage verses a higher voltage?

Low voltage hill climbing would be slower, and make the motor hotter.

Drawing 1800 watts from the battery would give me faster RPM, but does higher voltage give less torque thrust?

A smaller capacity battery pack you are also reducing it's capability to supply current under high loads without a lot of voltage sag (and stressing the cells). As well as it being easier to accidentally hit the turn off voltage.

Now my brain is fried, and I still don't know if this is correct:

Using 3400mAh GA cells:

96 cells in 8 packs of 12 in series = 40.8 Ah? at 48v?? [12 x 4.2v= 50.4v]

120 cells in 10 packs of 12 in series= 48.96 Ah 48volts? [12 x 4.2= 50.4v] would this give me the same average speeds of 11mph?

112 cells in 8 packs of 14 in series = 27.2Ah 52volts nominal. [14x 4.2v=58.8v]

112 cells in 7 packs of 16 in series = 23.8 Ah 60v nominal? [16 x 4.2v = 67.2v]

114 cells in 6 packs of 19 in series = 20.4 Ah 72v nominal? [19 x4.2=79.8v] ? or:

120 cells in 6 packs of 20 in series = 20.4Ah 72v? [20 x4.2v = 84v] but would 20Ah be enough at that voltage?

https://endless-sphere.com/forums/viewtopic.php?f=1&t=99337

I have an ammo box measured 11” x 6 3/4” x 5 5/8th inch inside leaving plenty room for the BMS on the top. 120 cells could fit into the box 10 x 6 x 2 = this will leave room between the 18650 cells for forced air from a pair of one inch thick fans. But maybe forcing air over the cells is not actually needed. I maybe could fit 132 cells without fans that I maynot need any how.

I am using a 52volt battery but the 13.5Ah [14s 4p = 56 cells 704watt hours] is half of what I really need. My motor sucks up to around 1800 watts on reasonably hard acceleration then drops back to around 1400 watts.

All I really need is more amp-hours. My worst hauling job yet was using an average of 53Wh per mile for about 500 total combined pounds over about 6.44 miles at 10.8 mph average. I usually use between 40 and 46Wh per mile over 9.6 to 11 miles round trip. At an average of 10.7 to 11.8 mph. And I do not use my legs; I developed severe arthritis in my knees by pedaling this kind of weight [400 to 500lbs] without a motor for way too many years.

I charge my battery to 80% the night before my trip to town, then up to 90% just before I leave about [45 minutes]. The last 10% takes too long.

So how would this Cyclone3000 behave at a lower voltage verses a higher voltage?

Low voltage hill climbing would be slower, and make the motor hotter.

Drawing 1800 watts from the battery would give me faster RPM, but does higher voltage give less torque thrust?

A smaller capacity battery pack you are also reducing it's capability to supply current under high loads without a lot of voltage sag (and stressing the cells). As well as it being easier to accidentally hit the turn off voltage.

Now my brain is fried, and I still don't know if this is correct:

Using 3400mAh GA cells:

96 cells in 8 packs of 12 in series = 40.8 Ah? at 48v?? [12 x 4.2v= 50.4v]

120 cells in 10 packs of 12 in series= 48.96 Ah 48volts? [12 x 4.2= 50.4v] would this give me the same average speeds of 11mph?

112 cells in 8 packs of 14 in series = 27.2Ah 52volts nominal. [14x 4.2v=58.8v]

112 cells in 7 packs of 16 in series = 23.8 Ah 60v nominal? [16 x 4.2v = 67.2v]

114 cells in 6 packs of 19 in series = 20.4 Ah 72v nominal? [19 x4.2=79.8v] ? or:

120 cells in 6 packs of 20 in series = 20.4Ah 72v? [20 x4.2v = 84v] but would 20Ah be enough at that voltage?