Hi guys

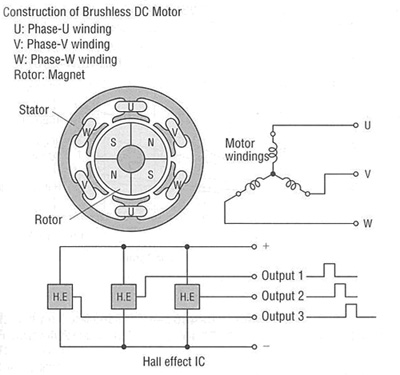

I have a question about hall sensors. I have an MXUS 3000w turbo motor and I used one of those white ebike testers on it to find out why the motor isnt working. The phase wires seem to work properly as the lights on the tester light up..but when I connect either set of hall sensors to the tester (the MXUS has 2 sets of halls), the lights on the tester dont light up.

Is it possible to use a sensorless controller on the motor and just only use the phase wires? Or would I need to replace the halls? Ive never done that before so thats why Im wondering if a sensorless controller will work.

Thanks in advance!

I have a question about hall sensors. I have an MXUS 3000w turbo motor and I used one of those white ebike testers on it to find out why the motor isnt working. The phase wires seem to work properly as the lights on the tester light up..but when I connect either set of hall sensors to the tester (the MXUS has 2 sets of halls), the lights on the tester dont light up.

Is it possible to use a sensorless controller on the motor and just only use the phase wires? Or would I need to replace the halls? Ive never done that before so thats why Im wondering if a sensorless controller will work.

Thanks in advance!