maarten_almighty

100 mW

- Joined

- Jan 10, 2020

- Messages

- 47

I am using a BLDC 3 phase hub motor and recently installed a motor controller rated for 3000watt (I originally had a 1200Watt controller installed).

The motor is rated for 500w nominal 800w peak but is currently probably producing approx 1000w power at the wheel (with the 3000watt controller installed).

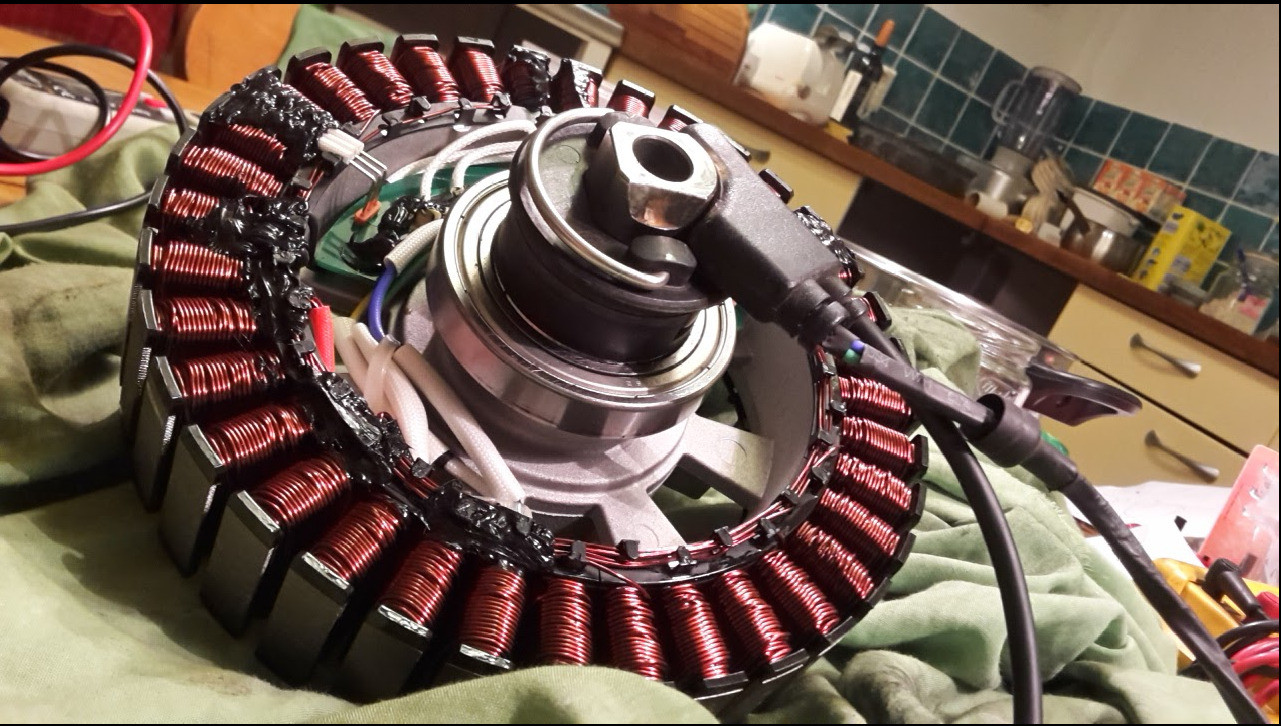

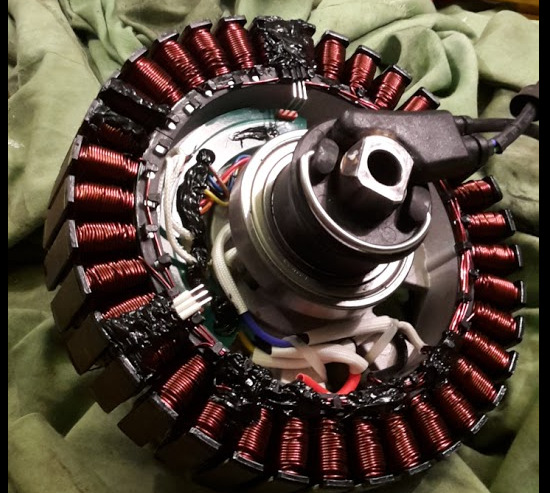

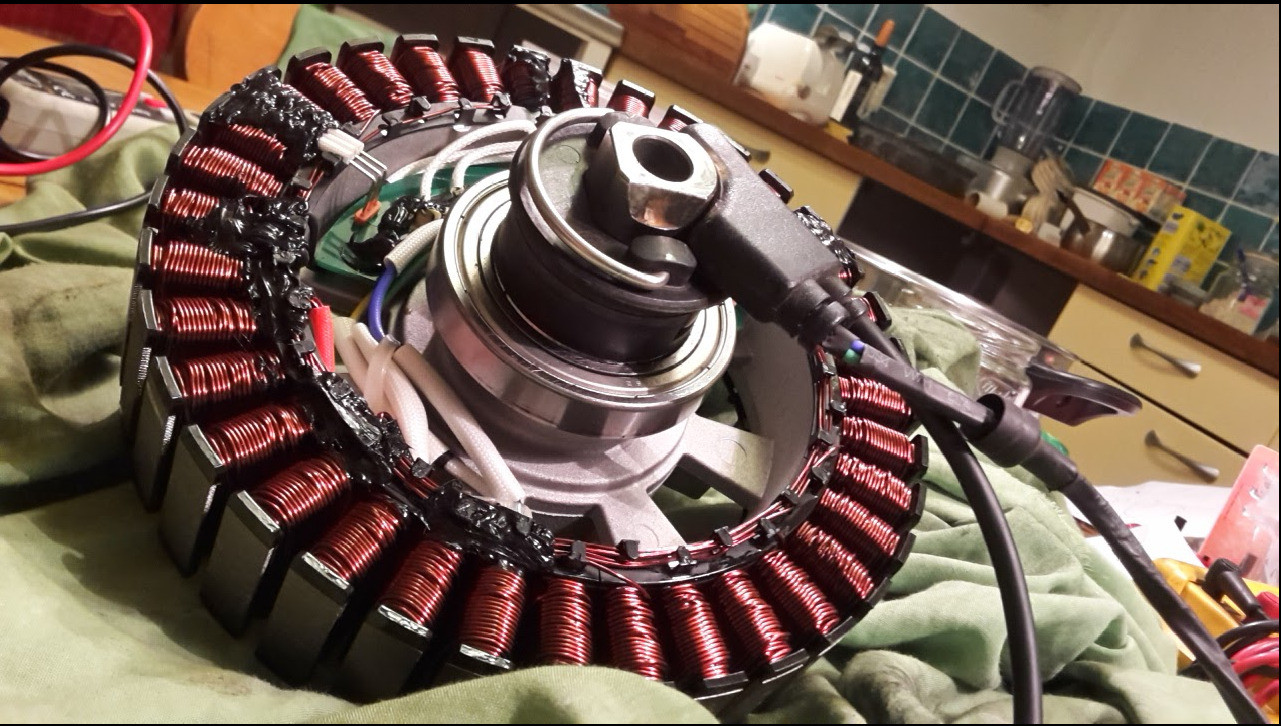

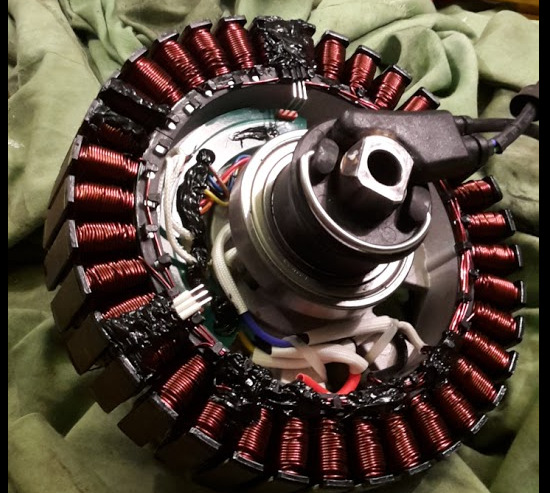

Photos:

( Note: currently used wires are much thicker than the ones in the photos, it's an old photo )

I'm running the motor at 72v (84v when battery fully charged), originally was intended for 36v/42v .

The power output/torque produced by the motor did increase after switching to the 3kW controller but not by a lot. It appears most of the extra watts going to the motor are going into heating up the motor.

The motor gets significantly hotter (gets hot in shorter amount of time) than with the previous controller.

The motor is running with hall sensors connected to controller (motor controller supports hall sensors)

I was wondering what design aspects of my BLDC motor would be the limiting factor (in terms of max useful output wattage).

Wires from controller to hub motor (3 phase wires) are 16mm2 each so probably not a limiting factor.

The performance appears a tiny bit better when the motor is cold but the output is still quite comparable to the 1200watt controller..

I think it's one of the following things:

- Stator magnetic core is saturated (I need a wider or bigger diameter stator?)**

- winding diameter too small *

- permanent magnets need to be bigger? (not sure if this would do much)

- motor needs better cooling *

*(probably not a big factor since motor performance when motor is cold is not far off from the wattage output (useful) I got with 1200watt controller))

**What design changes (for example more layers, other shape of magnetic core) would positively influence the magnetic saturation point (make it so that this point is reached later/at a higher amount of magnetic flux produced)?

Does the number of windings have any influence on the efficiency of the motor? I'd think longer overall path length of windings within motor would result in more voltage loss thus less efficiency.

The winding wire diameter is approx 1.5-2mm. I'm not sure how many layers of windings there are unfortunately (have not rewound this motor yet).

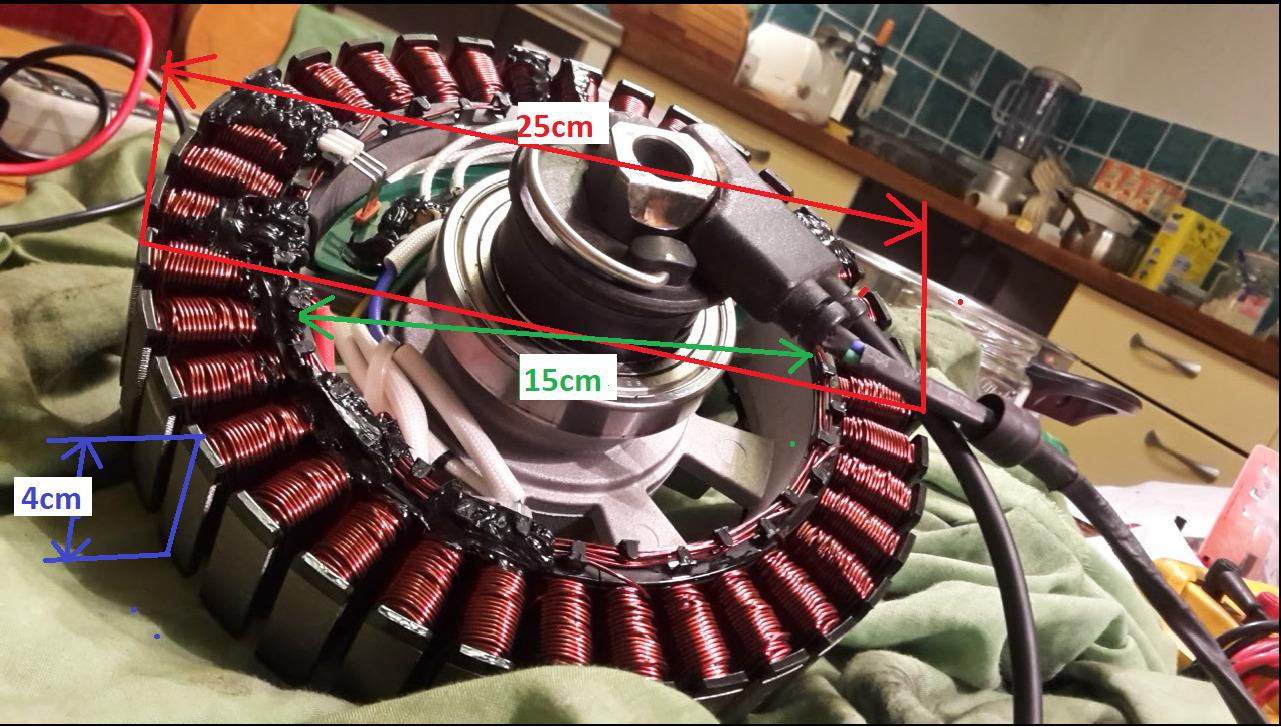

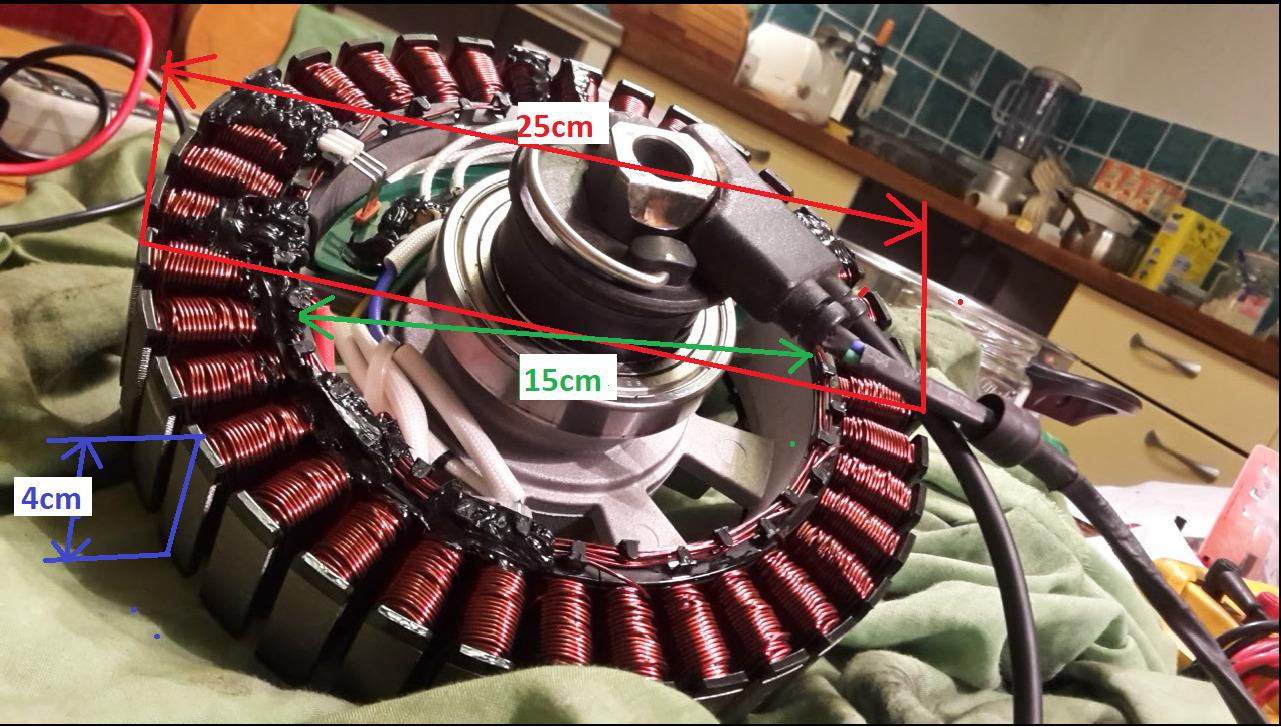

Stator's magnetic core outer diameter is approx 25cm, stator's magnetic core inner diameter is approx 15cm. See image:

( Note: currently used wires are much thicker than the ones in the photos, it's an old photo )

I've read that some people can get 10 times rated output power out of their hub motors but perhaps this is way too positive or my hub motor just isn't suited for that. Anyway I would love to know what the issue might be.

What changes could I theoretically make to my motor to get more power output at the wheel? Thank you!

The motor is rated for 500w nominal 800w peak but is currently probably producing approx 1000w power at the wheel (with the 3000watt controller installed).

Photos:

( Note: currently used wires are much thicker than the ones in the photos, it's an old photo )

I'm running the motor at 72v (84v when battery fully charged), originally was intended for 36v/42v .

The power output/torque produced by the motor did increase after switching to the 3kW controller but not by a lot. It appears most of the extra watts going to the motor are going into heating up the motor.

The motor gets significantly hotter (gets hot in shorter amount of time) than with the previous controller.

The motor is running with hall sensors connected to controller (motor controller supports hall sensors)

I was wondering what design aspects of my BLDC motor would be the limiting factor (in terms of max useful output wattage).

Wires from controller to hub motor (3 phase wires) are 16mm2 each so probably not a limiting factor.

The performance appears a tiny bit better when the motor is cold but the output is still quite comparable to the 1200watt controller..

I think it's one of the following things:

- Stator magnetic core is saturated (I need a wider or bigger diameter stator?)**

- winding diameter too small *

- permanent magnets need to be bigger? (not sure if this would do much)

- motor needs better cooling *

*(probably not a big factor since motor performance when motor is cold is not far off from the wattage output (useful) I got with 1200watt controller))

**What design changes (for example more layers, other shape of magnetic core) would positively influence the magnetic saturation point (make it so that this point is reached later/at a higher amount of magnetic flux produced)?

Does the number of windings have any influence on the efficiency of the motor? I'd think longer overall path length of windings within motor would result in more voltage loss thus less efficiency.

The winding wire diameter is approx 1.5-2mm. I'm not sure how many layers of windings there are unfortunately (have not rewound this motor yet).

Stator's magnetic core outer diameter is approx 25cm, stator's magnetic core inner diameter is approx 15cm. See image:

( Note: currently used wires are much thicker than the ones in the photos, it's an old photo )

I've read that some people can get 10 times rated output power out of their hub motors but perhaps this is way too positive or my hub motor just isn't suited for that. Anyway I would love to know what the issue might be.

What changes could I theoretically make to my motor to get more power output at the wheel? Thank you!