Good question! I doubt that statorade has been measured in W/mK, Justin has probably saved many hubs from overheating by popularizing stator cooling fluid, here are some related info:

Mercury 8.4

Hydrofluoric acid 2.33

Water, Fresh 0.609

Alcohol 0.204

Transformer oil 0.177

Oil, cylinder 0.152

Engine Oil 0.145

air 0.025

Copper : 400

Alumium : 200

quote:

the thermal conductivity coefficients for 5 Fe3O4‐S and 20 Fe3O4‐S ferrofluid also increased for ΔT = 35 K. At the highest magnetic field, the thermal conductivity coefficient, k, is measured as 0.51 and 0.47 W/mK for 20 and 5 vol%, respectively.

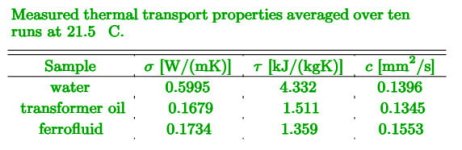

Another research saysthat ferrofluid designed for thermal transfer is about 20% more efficient than transformer oil.

https://www.researchgate.net/public...ristics_of_a_Transformer_Oil_Based_Ferrofluid

Another science thesis for ferrofluid cooling gave 2.05 W/mk for Ferrofluid compared to 1.77 for transformer oil.

Does the iron just stick to the neodynium magnets? does it bounce around between the coils and the magnets? does the iron jump from the side of the coils to the neodynium? Does the iron bounce from one coil to the other as the magnetic field changes? I think a lot will glue to the magnets. What do you think?

transformer oil is also used for datacenters so it's pretty gentle to the epoxy and glue in the stator apparently.

https://www.researchgate.net/public...rations_for_Oil_Immersion-Cooled_Data_Centers

The most accurate thing is to do a test with a thermal camera on three motors with air/oil/statorade, and see which goes red the fastest.

If you decide that machine oil is 5 times more performant than air, and 80% as good as Ferrofluid, then you have to get low viscosity oils... 0w8 is for hybrid toyotas, but it's pretty viscous still... sewing machine oil in the industry is used for light machine parts... viscous oil will reduce your range. You need sewing machine oil which protects from rust and doesn't turn acidic over time.

Either way, if you want to have green/blue/violet transformer oil in the engine it's the coolest.

https://www.ebay.fr/itm/152675837549?hash=item238c30666d:g:cYcAAOSw5cNYQHLv