Hello, and apologies if this is the wrong place to ask!

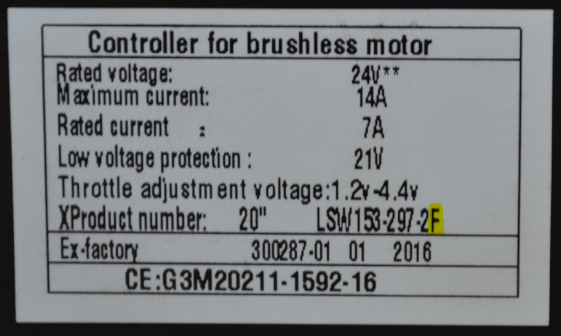

I am looking at two similar cargo bikes -- one has a Bafang 250w rear hub motor and a Lishui controller (I don't know the exact model numbers), the other a Bafang M400 mid-drive motor. I like the idea of the rear hub because it seems easier to maintain/replace down the road, but it does not have a torque sensor. The rear hub bike is also significantly less expensive.

This would be my first ebike, and I am definitely looking for a torque sensor ride -- I love biking but for car replacement I need more reliability and endurance than my legs can provide alone. I see that I can get aftermarket torque sensors, but I'm not sure what I need to connect it up. The Cycle Analyst method adds another device, meaning more money and more wires to deal with.

My questions: Is it possible to program the torque sensor into the existing controller, or a replacement controller? Am I right to be concerned about a built-in mid drive frame becoming obsolete in a few years?

I should add that I am not experienced with this kind of DIY electronic project, but I'm ok at following instructions.

Thanks for any advice!

I am looking at two similar cargo bikes -- one has a Bafang 250w rear hub motor and a Lishui controller (I don't know the exact model numbers), the other a Bafang M400 mid-drive motor. I like the idea of the rear hub because it seems easier to maintain/replace down the road, but it does not have a torque sensor. The rear hub bike is also significantly less expensive.

This would be my first ebike, and I am definitely looking for a torque sensor ride -- I love biking but for car replacement I need more reliability and endurance than my legs can provide alone. I see that I can get aftermarket torque sensors, but I'm not sure what I need to connect it up. The Cycle Analyst method adds another device, meaning more money and more wires to deal with.

My questions: Is it possible to program the torque sensor into the existing controller, or a replacement controller? Am I right to be concerned about a built-in mid drive frame becoming obsolete in a few years?

I should add that I am not experienced with this kind of DIY electronic project, but I'm ok at following instructions.

Thanks for any advice!