auraslip

10 MW

- Joined

- Mar 5, 2010

- Messages

- 3,535

So this is probably my fault

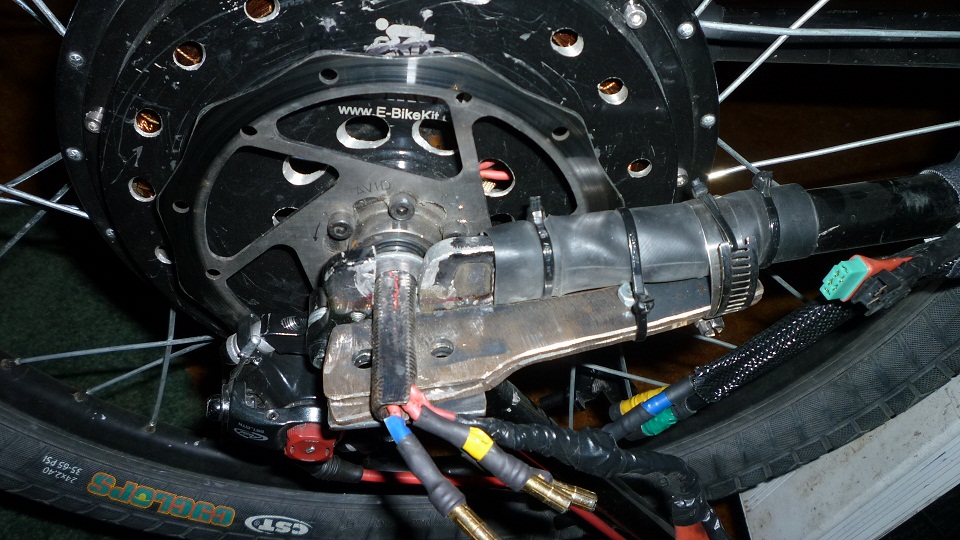

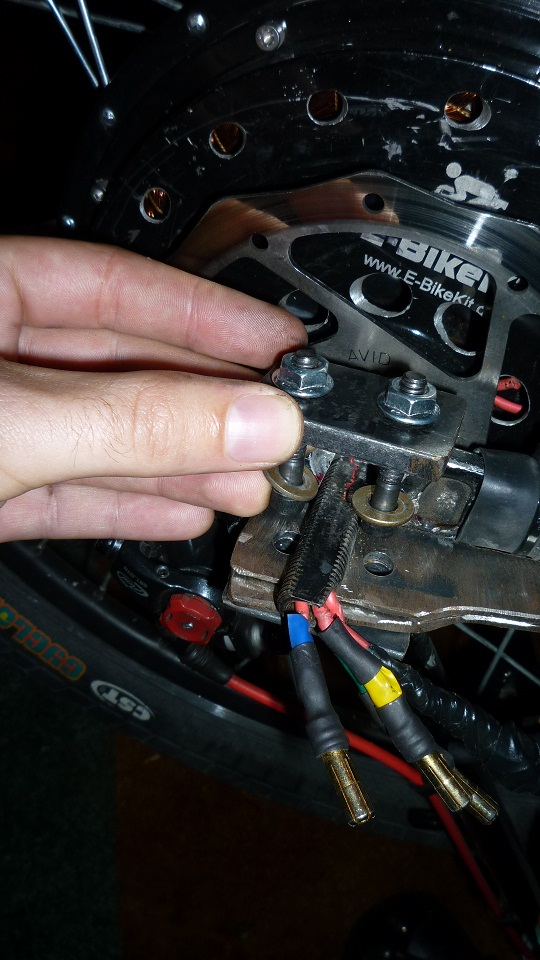

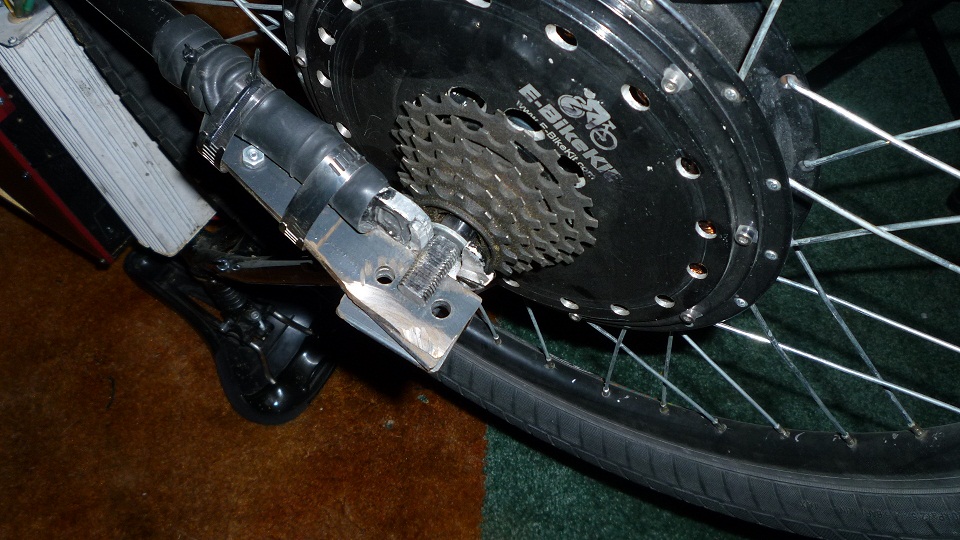

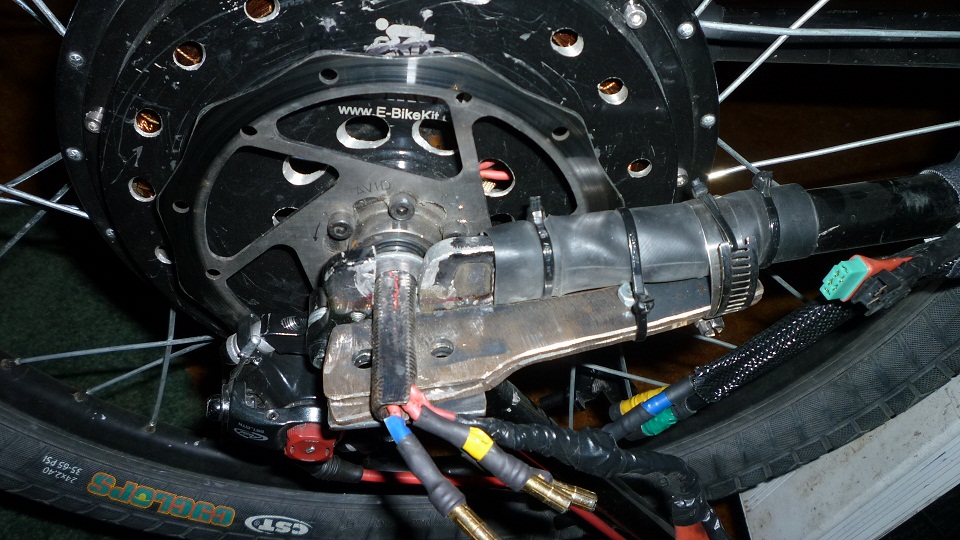

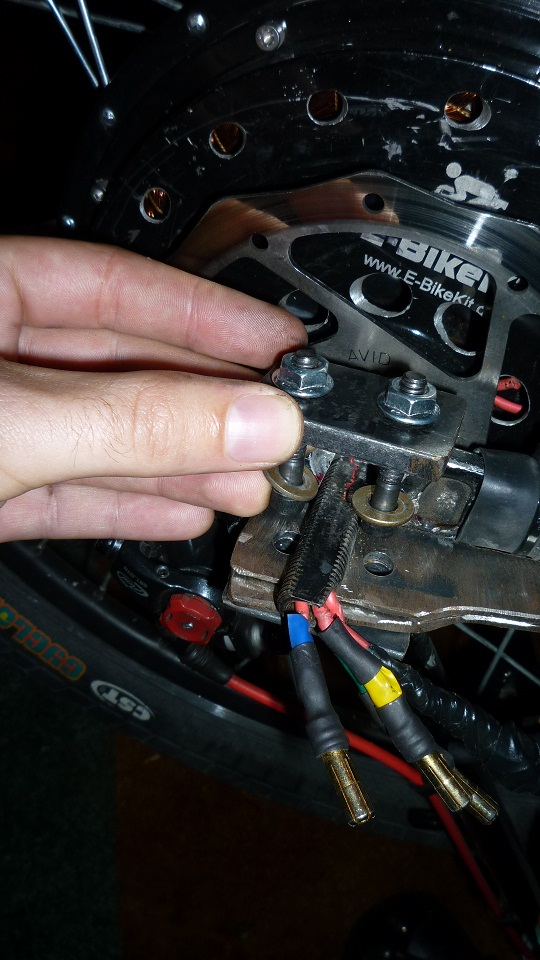

Axle is drilled out to accommodate bigger wires, and the drive side was shortened last year (when I was an idiot) to keep it from rubbing the derailleur. Bike was running 22s with an 18 fet lyen.... probably maxing 8kw bursts....

Possibly, the clamping drop outs were overtightened too.

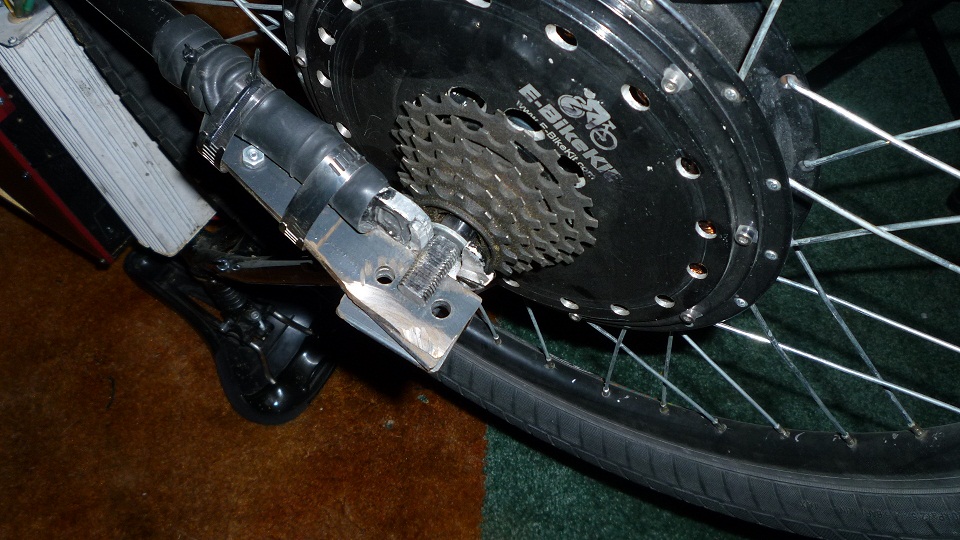

On the flip side, this proves how well clamping drop outs work..... cause I rode like this daily for a month.

It just sucks for a lot of reasons. Ya'll probably noticed I haven't been posting for the last month. I had a bit of a mental breakdown about school, money, finishing this damn bike, and of course a girl. I've spent the last month trying to work my self out of a pretty deep depression. I guess you can call it burn out syndrome. And now my finally finished bike is dead in the water, with no chance for repair, and no money for a new motor. Also I spent like HOURS modding that god damn motor. $T@#$%@%@

It's kinda funny actually. I hate that bike now. So much frustration. Want to set it on fire. Most of you would probably love that bike though. It maxes at 50mph, does wheelies, and handles like a dream. And it's rain proof with the batteries in a box in the triangle. Any one in the DFW metroplex wanna buy it? :lol:

Oh, and yesterday, the kickstand on my other bike broke

But the crowecycles people said they'd send me a new one (steel not AL this time)

Axle is drilled out to accommodate bigger wires, and the drive side was shortened last year (when I was an idiot) to keep it from rubbing the derailleur. Bike was running 22s with an 18 fet lyen.... probably maxing 8kw bursts....

Possibly, the clamping drop outs were overtightened too.

On the flip side, this proves how well clamping drop outs work..... cause I rode like this daily for a month.

It just sucks for a lot of reasons. Ya'll probably noticed I haven't been posting for the last month. I had a bit of a mental breakdown about school, money, finishing this damn bike, and of course a girl. I've spent the last month trying to work my self out of a pretty deep depression. I guess you can call it burn out syndrome. And now my finally finished bike is dead in the water, with no chance for repair, and no money for a new motor. Also I spent like HOURS modding that god damn motor. $T@#$%@%@

It's kinda funny actually. I hate that bike now. So much frustration. Want to set it on fire. Most of you would probably love that bike though. It maxes at 50mph, does wheelies, and handles like a dream. And it's rain proof with the batteries in a box in the triangle. Any one in the DFW metroplex wanna buy it? :lol:

Oh, and yesterday, the kickstand on my other bike broke

But the crowecycles people said they'd send me a new one (steel not AL this time)