Raged

1 kW

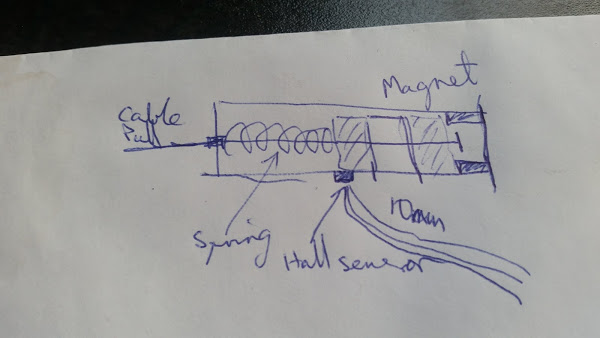

I'm building a cable operated linear throttle for my new build where I will use the front deraileur adjustment on a STI (dropbar) arrangement on a custom 29er setup.

Am I right in thinking this is pretty much how a hall sensor throttle can be set up?

Is there anything more complicated I'm not taking into account?

Am I right in thinking this is pretty much how a hall sensor throttle can be set up?

Is there anything more complicated I'm not taking into account?