zukster

1 kW

When I tried to setup my Q100C CST with Grin's Phaserunner(PR), I quickly destroyed the stock freewheel clutch springs while dialing in the motor after doing the PR software's autotune.

I think a lot of other people like this light rear hub motor, so I thought I'd post this info in case anyone else want to run it with a PR. Once its tuned up properly, you can squeeze a lot of torque and speed out of it with the PR. I will cover this in another thread as I am still fine tuning it.

Until the motor is tuned fairly well, the PR can cause some kind of feedback pulsing while trying to synchronize with the motor upon hitting the throttle. This can happen at reasonable power levels, without trying higher than recommend power or voltage levels.

Before I could continue dialing in my PR motor config, I had to upgrade the clutch springs.

This requires opening up the motor. I showed this here:

https://endless-sphere.com/forums/viewtopic.php?f=2&t=86991

I don't show it above but to get to the springs you remove axle nuts on the cassette side, then tap the freehub and cap off. You don't need a lot of force. I bang the end of the axle lightly on the work bench and the cap pops of the motor internals.

Pictures of the clutch and spring are at the end of this.

To be clear on which motor I have, it is the Q100C CST Cassette 201RPM motor sold by BMSBattery:

https://bmsbattery.com/ebike-kit/651-q100c-cst-36v350w-32-hole-rear-driving-hub-motor-ebike-kit.html

Some people think this is the same as the Aikema

http://www.aikema.com.cn/En_ArticleShow.asp?ArticleID=294

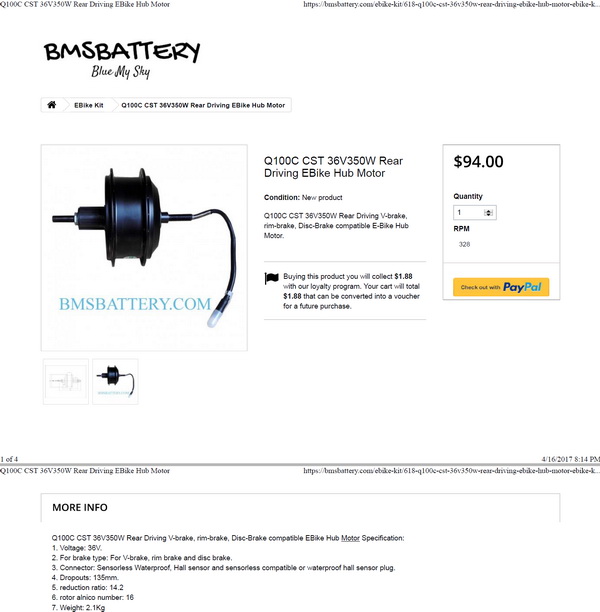

motor but someone in another ES thread met Jack Xie of BMSBattery at a trade show and he said they are not made by Aikema. Also, if you dig into the Aikema specs in more detail, you will find that the flange to flange width is speced at 47mm. I measured my Q100C CST from BMSBattery and the flange to flange width is 42mm, measured from the center of one flange to the other (not the edge). The Aikema ZYJZ-100SX reduction ratio is listed at 14.2, which is the same as what BMSBasttery had list on one of their pages on April 27, 2017. I can't find the page now but I snagged a pdf of it at the time for future reference:

A few years ago, the BMSBattery Q100C CST being sold was a bit different. It was 47mm and about 5 pounds. Also, the freehub was a bit different and you could pop it off simply by undoing the axle nuts. Also, it was silver colored or polished aluminum in color. The newer Q100C CST is black, 42mm flange to flange and weighs about 4.5 pounds. Perhaps BMSbattery made their own slightly different, smaller, lighter version of it. I don't really know. I like the new BMSBattery Q100C CST as it is pretty much the smallest lightest rear cassette hub motor you can find.

To start with, I measured the springs as best I could from an undamaged spare motor: 3.8mm x 16mm. In another ES thread, which I can't find now, someone measured the diameter as 3.85 and the thickness of the spring wire at 0.35mm. They guessed or measured the hole diameter as 4mm. So what I wanted was new stronger springs that are:

Outer Diameter: 3.5 - 3.8mm or 0.14 - 0.15"

Wire Diameter: 0.5 - 0.8mm or 0.0197 - 0.0315"

Loose Length: 16 - 18mm or 0.630 - 0.709"

Solid Length: 10mm or 0.39"

Outer Diameter: 0.14 - 0.15 "

Wire Diameter: 0.0197 - 0.0315 "

Loose Length: 0.630 - 0.709 "

Solid Length: 0.39 "

The thicker the spring wire the better so that when the clutch is rapidly engaged and disengaged by PR pulsing, the srings will not get pinched and damaged.

The online shop that had the closest to what I wanted is Century Spring:

http://www.centuryspring.com/compression/compression-springs.html?od_inches=0.14%2C0.15&freelength_inches=0.63%2C0.71&wire_dia_inches=0.02%2C0.04

Stock# OD(in) Ln(in) lbs/in SL(in) WD(in)

Q-95 0.140 0.630 65.000 0.470 0.030

MM-5 0.140 0.660 90.000 0.430 0.032

70232S 0.148 0.690 14.000 0.340 0.023

70231S 0.148 0.630 15.000 0.310 0.023

OD=Outer Diameter, Ln=Length uncompressed

lbs/in=rate(strength), SL=compressed Solid Length

WD=Wire Diameter

Shipping was half my cost so I ordered all of these to try.

The Q-95's are too strong and long. The 70231S's fit perfectly.

At first it seems impossible to get the springs in while trying to compress them and get the little steel cylinder in place. With persistence it can be done with jewelers screwdrivers to compress the springs while inserting the cylinder. But there is a trick I learned where you first take the clutch cap off and then get the springs in place with the cylinders at their ends. Then you put the cap back on, rotate clockwise while pushing down hard on the cap. This will push the cylinders toward the springs and compress them, and then the cap will snap down to hold everything in place. Pictures to come as soon as I get one opened again.

I tried the 70231S first but for ride tests I could still hear what I though was a spring pinch grind noise when testing PR settings.

So for testing I decided to go with the MM-5's. They fit was a bit too tight/strong at their stock length, so I cut exactly 1 circular coil wind off each spring, ie. a 360 degree loop. This is still hard to freewheel but the wheel spinning easily breaks the clutch free. It is hard to break free by hand. And since these are the thickest springs available, they will be very pinch damage resistant.

So far these feel better as I went through more PR testing. There was a lot of resistance to rolling the wheel forward at first. This has loosened up a bit after a few hours of testing and riding and the wheel spins more freely now.

Once I am fully satisfied with the PR dialed in to the motor, I might switch back to the 70231S's and see if they work okay once the PR throttle feedback pulsing has been eliminated. Or perhaps the 70232S's, which are the same as the 70231S's, but a bit longer, so will be a bit stronger.

I'm not really sure if you need the strongest spring possible once the PR is dialed in. If not, the thinner wire diameter 70231S/70232S springs will provide less wheel rolling resistance, which will be possibly less boggy (like driving your car with the ebrake accidentally on a bit), and more efficient.

But I may find that the stronger MM-5's really are needed when running the Q100C CST at higher power levels. I'll update this post when I know more certainly.

.

.

.

.

.

.

.

When reassembling the clutch and sliding parts, I wanted some lubrication and rust protection, but not too slippery as to slip the clutch too easily.

I used a light coating of high temp silicone disk brake quite. Its is not too thick when heated up and not quite as slippery as synthetic or Teflon gear lubes. I think a light bike based bike lube like Tri-Flow would be too slippery as it has Teflon. 3-in-1 machine oil would probably be okay.

Whatever you use, you don't want too much. I made the mistake of using a liberal dose of Fluid-Film, and I was getting clutch slippage after.

I think a lot of other people like this light rear hub motor, so I thought I'd post this info in case anyone else want to run it with a PR. Once its tuned up properly, you can squeeze a lot of torque and speed out of it with the PR. I will cover this in another thread as I am still fine tuning it.

Until the motor is tuned fairly well, the PR can cause some kind of feedback pulsing while trying to synchronize with the motor upon hitting the throttle. This can happen at reasonable power levels, without trying higher than recommend power or voltage levels.

Before I could continue dialing in my PR motor config, I had to upgrade the clutch springs.

This requires opening up the motor. I showed this here:

https://endless-sphere.com/forums/viewtopic.php?f=2&t=86991

I don't show it above but to get to the springs you remove axle nuts on the cassette side, then tap the freehub and cap off. You don't need a lot of force. I bang the end of the axle lightly on the work bench and the cap pops of the motor internals.

Pictures of the clutch and spring are at the end of this.

To be clear on which motor I have, it is the Q100C CST Cassette 201RPM motor sold by BMSBattery:

https://bmsbattery.com/ebike-kit/651-q100c-cst-36v350w-32-hole-rear-driving-hub-motor-ebike-kit.html

Some people think this is the same as the Aikema

http://www.aikema.com.cn/En_ArticleShow.asp?ArticleID=294

motor but someone in another ES thread met Jack Xie of BMSBattery at a trade show and he said they are not made by Aikema. Also, if you dig into the Aikema specs in more detail, you will find that the flange to flange width is speced at 47mm. I measured my Q100C CST from BMSBattery and the flange to flange width is 42mm, measured from the center of one flange to the other (not the edge). The Aikema ZYJZ-100SX reduction ratio is listed at 14.2, which is the same as what BMSBasttery had list on one of their pages on April 27, 2017. I can't find the page now but I snagged a pdf of it at the time for future reference:

A few years ago, the BMSBattery Q100C CST being sold was a bit different. It was 47mm and about 5 pounds. Also, the freehub was a bit different and you could pop it off simply by undoing the axle nuts. Also, it was silver colored or polished aluminum in color. The newer Q100C CST is black, 42mm flange to flange and weighs about 4.5 pounds. Perhaps BMSbattery made their own slightly different, smaller, lighter version of it. I don't really know. I like the new BMSBattery Q100C CST as it is pretty much the smallest lightest rear cassette hub motor you can find.

To start with, I measured the springs as best I could from an undamaged spare motor: 3.8mm x 16mm. In another ES thread, which I can't find now, someone measured the diameter as 3.85 and the thickness of the spring wire at 0.35mm. They guessed or measured the hole diameter as 4mm. So what I wanted was new stronger springs that are:

Outer Diameter: 3.5 - 3.8mm or 0.14 - 0.15"

Wire Diameter: 0.5 - 0.8mm or 0.0197 - 0.0315"

Loose Length: 16 - 18mm or 0.630 - 0.709"

Solid Length: 10mm or 0.39"

Outer Diameter: 0.14 - 0.15 "

Wire Diameter: 0.0197 - 0.0315 "

Loose Length: 0.630 - 0.709 "

Solid Length: 0.39 "

The thicker the spring wire the better so that when the clutch is rapidly engaged and disengaged by PR pulsing, the srings will not get pinched and damaged.

The online shop that had the closest to what I wanted is Century Spring:

http://www.centuryspring.com/compression/compression-springs.html?od_inches=0.14%2C0.15&freelength_inches=0.63%2C0.71&wire_dia_inches=0.02%2C0.04

Stock# OD(in) Ln(in) lbs/in SL(in) WD(in)

Q-95 0.140 0.630 65.000 0.470 0.030

MM-5 0.140 0.660 90.000 0.430 0.032

70232S 0.148 0.690 14.000 0.340 0.023

70231S 0.148 0.630 15.000 0.310 0.023

OD=Outer Diameter, Ln=Length uncompressed

lbs/in=rate(strength), SL=compressed Solid Length

WD=Wire Diameter

Shipping was half my cost so I ordered all of these to try.

The Q-95's are too strong and long. The 70231S's fit perfectly.

At first it seems impossible to get the springs in while trying to compress them and get the little steel cylinder in place. With persistence it can be done with jewelers screwdrivers to compress the springs while inserting the cylinder. But there is a trick I learned where you first take the clutch cap off and then get the springs in place with the cylinders at their ends. Then you put the cap back on, rotate clockwise while pushing down hard on the cap. This will push the cylinders toward the springs and compress them, and then the cap will snap down to hold everything in place. Pictures to come as soon as I get one opened again.

I tried the 70231S first but for ride tests I could still hear what I though was a spring pinch grind noise when testing PR settings.

So for testing I decided to go with the MM-5's. They fit was a bit too tight/strong at their stock length, so I cut exactly 1 circular coil wind off each spring, ie. a 360 degree loop. This is still hard to freewheel but the wheel spinning easily breaks the clutch free. It is hard to break free by hand. And since these are the thickest springs available, they will be very pinch damage resistant.

So far these feel better as I went through more PR testing. There was a lot of resistance to rolling the wheel forward at first. This has loosened up a bit after a few hours of testing and riding and the wheel spins more freely now.

Once I am fully satisfied with the PR dialed in to the motor, I might switch back to the 70231S's and see if they work okay once the PR throttle feedback pulsing has been eliminated. Or perhaps the 70232S's, which are the same as the 70231S's, but a bit longer, so will be a bit stronger.

I'm not really sure if you need the strongest spring possible once the PR is dialed in. If not, the thinner wire diameter 70231S/70232S springs will provide less wheel rolling resistance, which will be possibly less boggy (like driving your car with the ebrake accidentally on a bit), and more efficient.

But I may find that the stronger MM-5's really are needed when running the Q100C CST at higher power levels. I'll update this post when I know more certainly.

.

.

.

.

.

.

.

When reassembling the clutch and sliding parts, I wanted some lubrication and rust protection, but not too slippery as to slip the clutch too easily.

I used a light coating of high temp silicone disk brake quite. Its is not too thick when heated up and not quite as slippery as synthetic or Teflon gear lubes. I think a light bike based bike lube like Tri-Flow would be too slippery as it has Teflon. 3-in-1 machine oil would probably be okay.

Whatever you use, you don't want too much. I made the mistake of using a liberal dose of Fluid-Film, and I was getting clutch slippage after.