wil

10 W

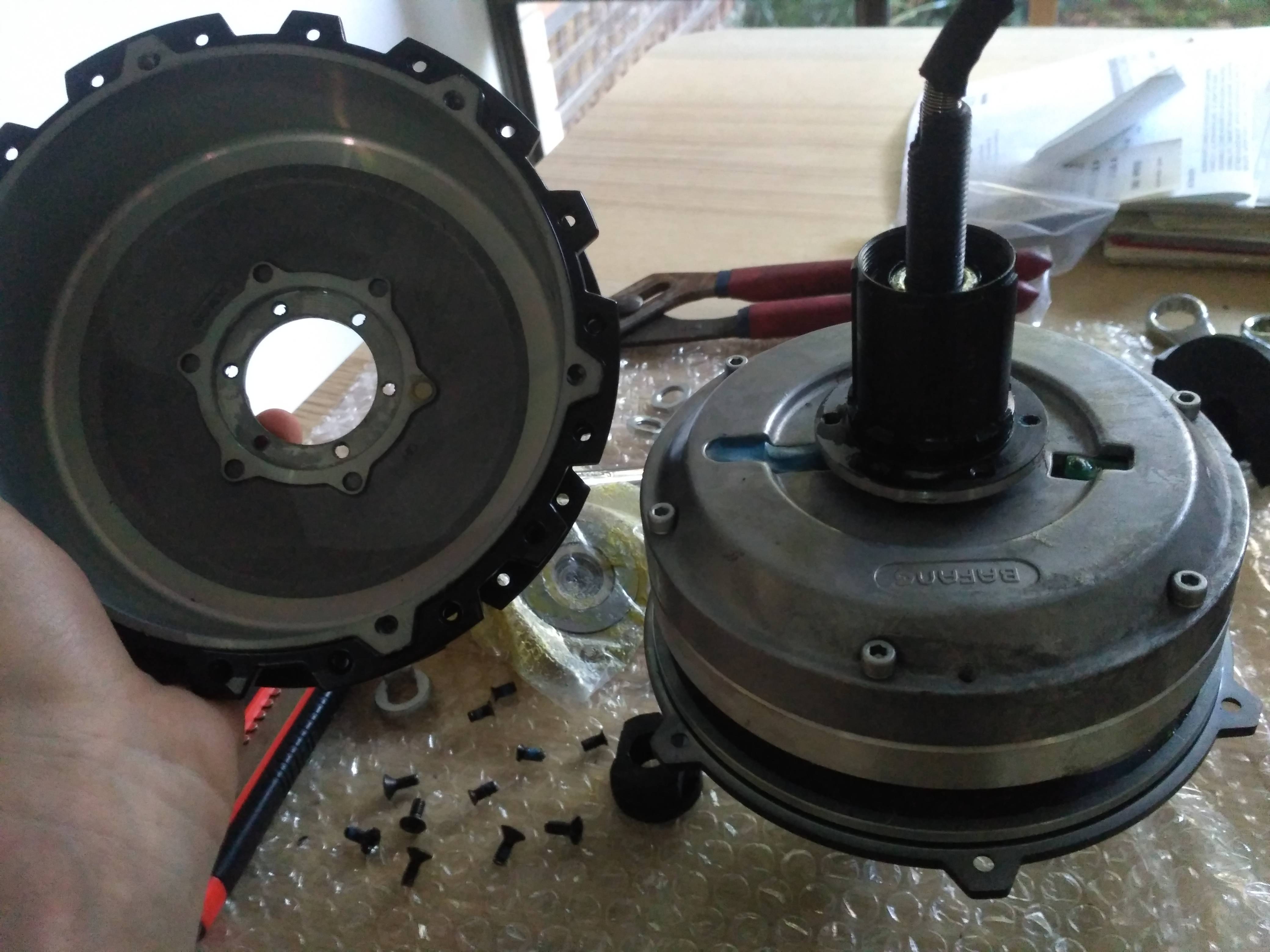

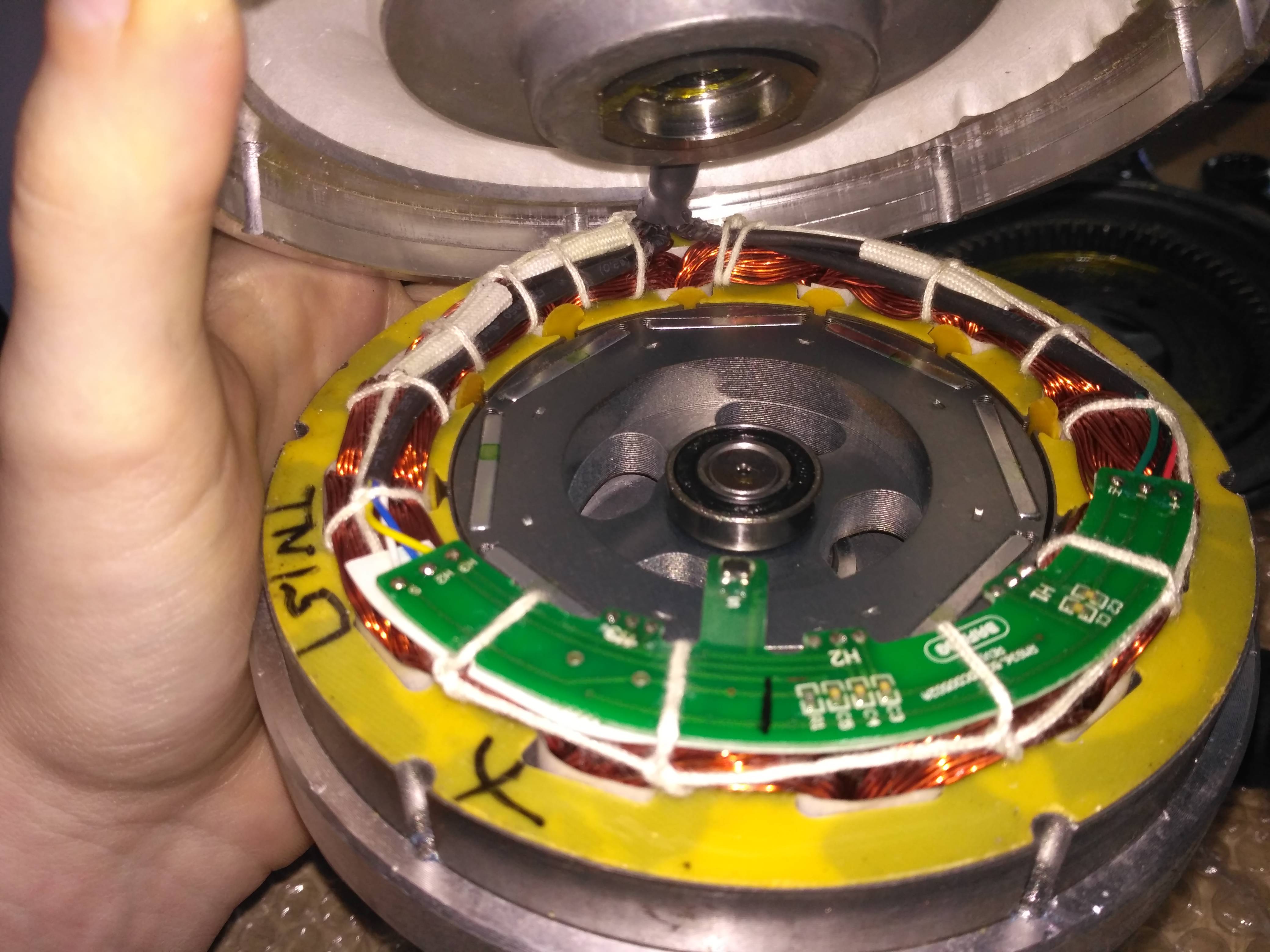

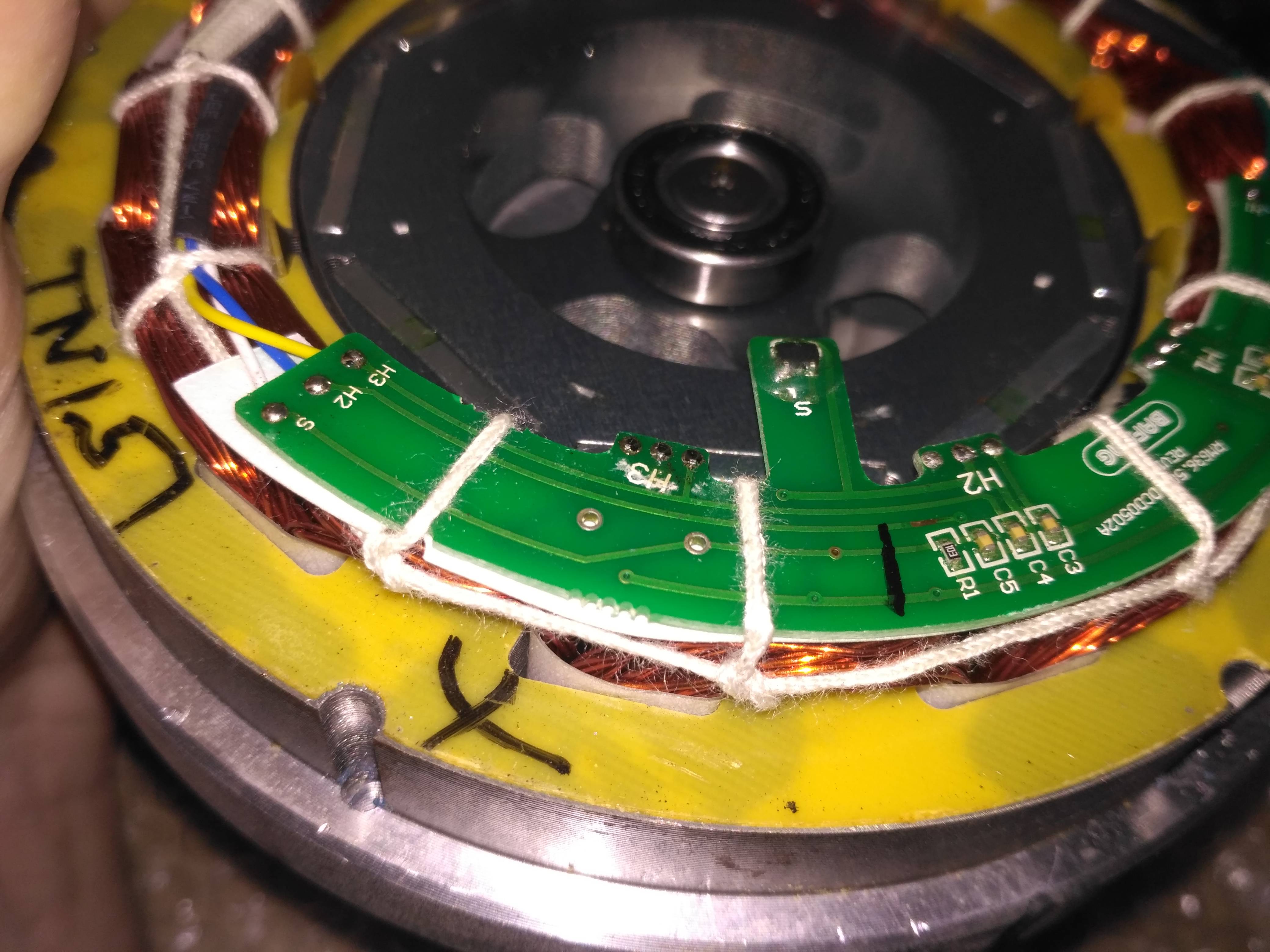

The Bafang G3xx series seem to offer some interesting motors that fit standard dropout spacing with disk brake compatibility - There is already a thread for the G310/G311 https://endless-sphere.com/forums/viewtopic.php?f=2&t=92124 so I won't mention those here aside from listing it's specs for comparison sake: 11:1 reduction ratio, 135mm diameter, 138mm width, Inrunner with 16 poles, 30nm max torque, 2.7kg. https://www.bafang-e.com/cn/components/component/motor/rm-g310250dc.html. (I'll call this Mini size). Read other thread for details but it looks like it has ridiculous power density, especially with oil cooling.

One of the other high reduction ratio motors in this series that seems interesting is the

FM G370.250.D/V https://www.bafang-e.com/en/components/component/motor/fm-g370250dv.html.

Similar to the G310, 16 pole count inrunner, in a smaller 100mm diameter motor (I'll call Micro size), the front motor version is standard 100mm width. Why is this motor interesting? It has a 12.5:1 reduction ratio and despite weighing just 1.7kg can output 42nm of torque! (Supposedly...). Like the G3xx it's rated for 250watt

Unfortunately the rear version RM G370.250.DC https://www.bafang-e.com/en/components/component/motor/rm-g370250dc.htmlis a wider 145mm, more than I would comfortable stretch a standard rear dropout.

The other motor of interest is the RM G360.500.DC https://www.bafang-e.com/en/components/component/motor/rm-g360500dc.html.

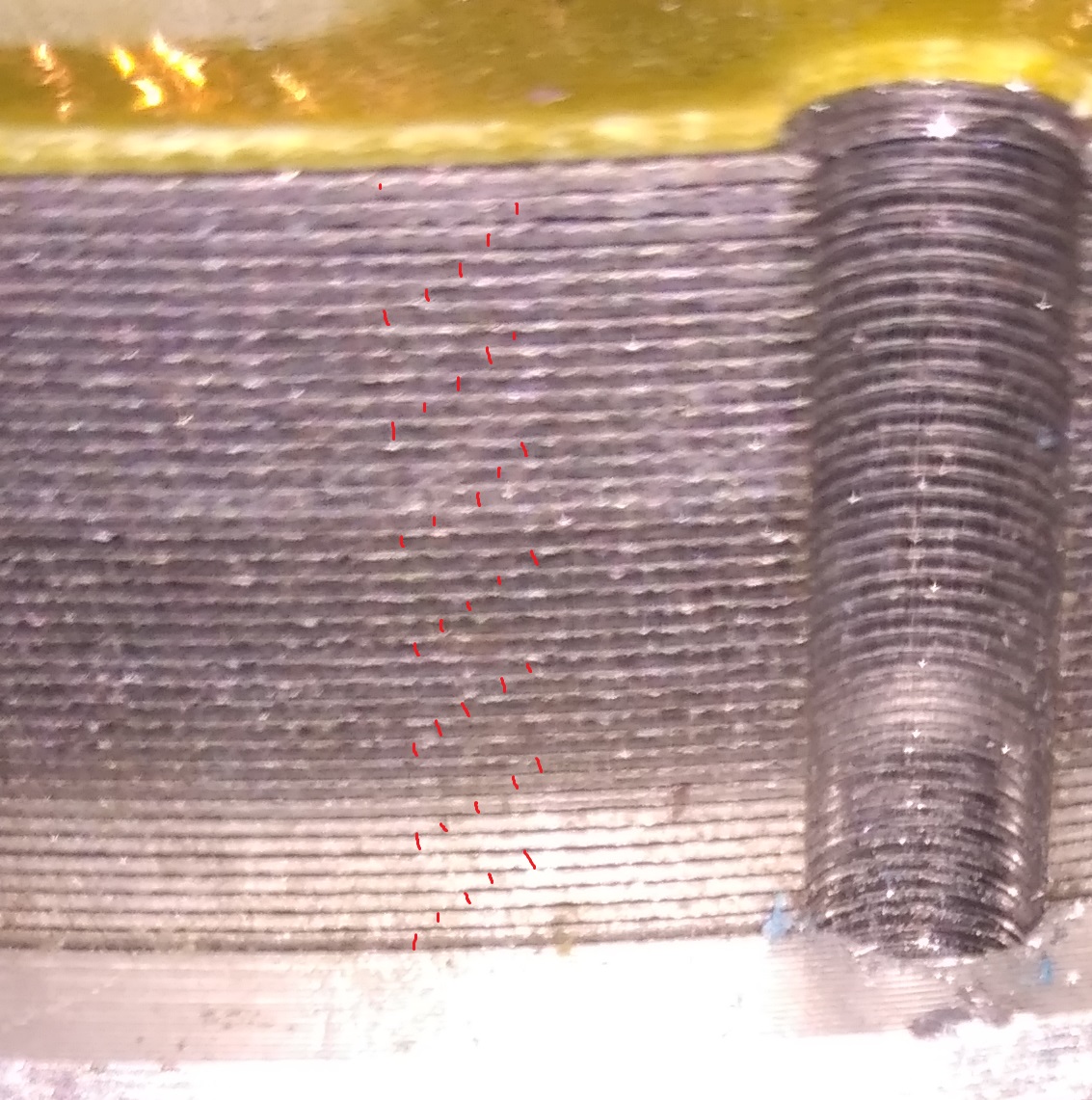

This is a larger 170mm diameter (I'll call standard) motor, ie similar in size to a mac. This one has a 12.8:1 reduction ratio, weight of 4.1kg. Standard (with stretch) dropout width of 138mm. Rated for 500 watts and 50nm of torque this seems to be the bigger brother of the G310. The pole count for this one is very low, just 8 poles. I THINK this one is an inrunner too (it's described as "having an Inner rotor" on the Bafang website). If the magnets don't get thrown off at high RPM like the G310 this one may be able to put out some decent power/speeds for it's size without hitting super high eRPM. I think this may be an issue with this one though due to the increased diameter causing more force + a higher reduction ratio meaning higher RPM.

These motors seem to be quite new (2018?) so I can't find much information about them apart from on the official bafang website and 1 short thread on 1 russian forum https://electrotransport.ru/ussr/index.php?topic=56542.0. (Interestingly after a google translate they mention the G370 as possibly running hot, although this could have been an early design)

I also cannot find any suppliers aside from 1 Alibaba supplier, Yongkang Gomax who lists all their motors as "2018 Bafang" (why bother actually putting the model name in the title where it is searchable? :x ).

Anyway to save others going through every single one of their product pages working out which is which I think its as follows

Front G370 (micro) https://cngomax.en.alibaba.com/prod...08/2018_Gomax_Bafang_Brushless_Hub_Motor.htmlNote, there is no model number, this is purely based on the torque figure and weight or https://cngomax.en.alibaba.com/prod...ang_Mid_Drive_Brushless_Geared_Hub_Motor.html

Rear G370 (micro) https://www.alibaba.com/product-detail/2018-Bafang-Hub-Motor-48V-500W_60777932423.html

Rear G360 (standard) https://www.alibaba.com/product-detail/2018-New-Brushless-Geared-Bafang-8Fun_60775162265.html

They also seem to supply the G310 (the only supplier I've found other than Grin).

Front G310/G311 (mini) https://cngomax.en.alibaba.com/prod...Use_For_Electric_Bicycle_Motor_Brushless.html

Rear G310 (mini) I don't think they supply, at least I can't find it on any of their listings.

If anyone finds any more information on these motors feel free to share, they look very interesting with their high reduction ratios. If they are anything like the G310 they should also be able to put out some decent power, especially with oil.

One of the other high reduction ratio motors in this series that seems interesting is the

FM G370.250.D/V https://www.bafang-e.com/en/components/component/motor/fm-g370250dv.html.

Similar to the G310, 16 pole count inrunner, in a smaller 100mm diameter motor (I'll call Micro size), the front motor version is standard 100mm width. Why is this motor interesting? It has a 12.5:1 reduction ratio and despite weighing just 1.7kg can output 42nm of torque! (Supposedly...). Like the G3xx it's rated for 250watt

Unfortunately the rear version RM G370.250.DC https://www.bafang-e.com/en/components/component/motor/rm-g370250dc.htmlis a wider 145mm, more than I would comfortable stretch a standard rear dropout.

The other motor of interest is the RM G360.500.DC https://www.bafang-e.com/en/components/component/motor/rm-g360500dc.html.

This is a larger 170mm diameter (I'll call standard) motor, ie similar in size to a mac. This one has a 12.8:1 reduction ratio, weight of 4.1kg. Standard (with stretch) dropout width of 138mm. Rated for 500 watts and 50nm of torque this seems to be the bigger brother of the G310. The pole count for this one is very low, just 8 poles. I THINK this one is an inrunner too (it's described as "having an Inner rotor" on the Bafang website). If the magnets don't get thrown off at high RPM like the G310 this one may be able to put out some decent power/speeds for it's size without hitting super high eRPM. I think this may be an issue with this one though due to the increased diameter causing more force + a higher reduction ratio meaning higher RPM.

These motors seem to be quite new (2018?) so I can't find much information about them apart from on the official bafang website and 1 short thread on 1 russian forum https://electrotransport.ru/ussr/index.php?topic=56542.0. (Interestingly after a google translate they mention the G370 as possibly running hot, although this could have been an early design)

I also cannot find any suppliers aside from 1 Alibaba supplier, Yongkang Gomax who lists all their motors as "2018 Bafang" (why bother actually putting the model name in the title where it is searchable? :x ).

Anyway to save others going through every single one of their product pages working out which is which I think its as follows

Front G370 (micro) https://cngomax.en.alibaba.com/prod...08/2018_Gomax_Bafang_Brushless_Hub_Motor.htmlNote, there is no model number, this is purely based on the torque figure and weight or https://cngomax.en.alibaba.com/prod...ang_Mid_Drive_Brushless_Geared_Hub_Motor.html

Rear G370 (micro) https://www.alibaba.com/product-detail/2018-Bafang-Hub-Motor-48V-500W_60777932423.html

Rear G360 (standard) https://www.alibaba.com/product-detail/2018-New-Brushless-Geared-Bafang-8Fun_60775162265.html

They also seem to supply the G310 (the only supplier I've found other than Grin).

Front G310/G311 (mini) https://cngomax.en.alibaba.com/prod...Use_For_Electric_Bicycle_Motor_Brushless.html

Rear G310 (mini) I don't think they supply, at least I can't find it on any of their listings.

If anyone finds any more information on these motors feel free to share, they look very interesting with their high reduction ratios. If they are anything like the G310 they should also be able to put out some decent power, especially with oil.