Yesterday I went to the mountains and I did cycle 140kms and it was hard. That gave me the opportunity to real test my EBike with M500 and I would like to share what I found:

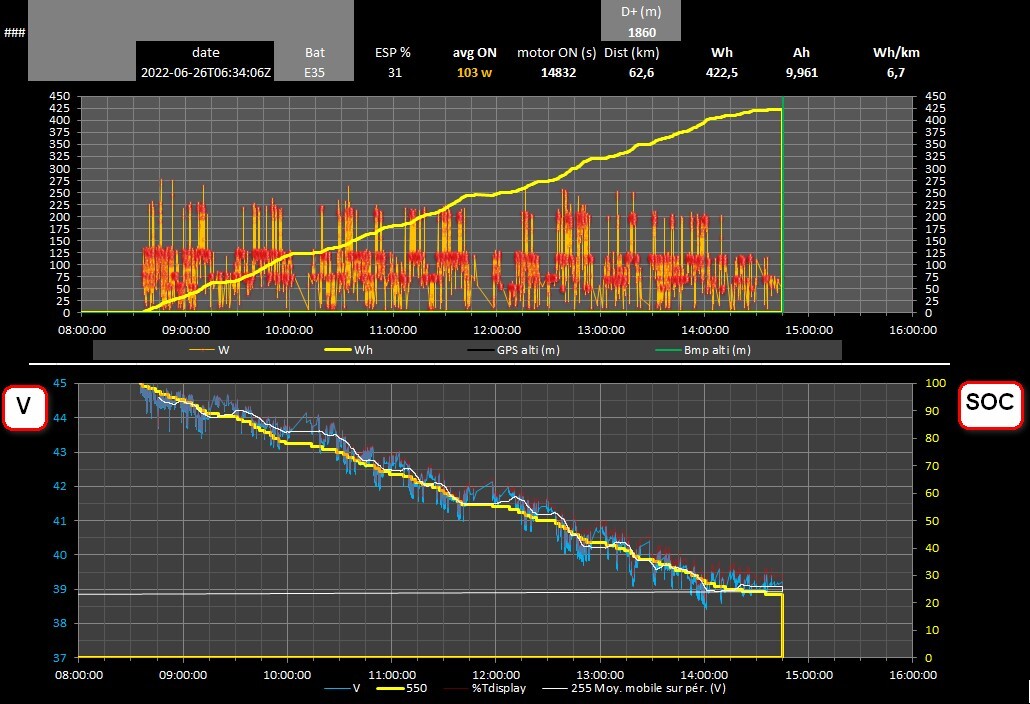

1. 52V battery with a M500 48V motor: My M500 was bought as a 48V battery but soon I found it would start to limit the motor power very soon when the battery was like at 50% SOC. Since I built my own battery, I decided to add more 1 series from 48V 13 to 52V 14S, as recommended by one user, so the motor power limitation would start later. And this worked very well!! The SOC on the display was 99% for a long time, because the M500 was calculation the SOC for a 48V battery. I also could see that at 40% SOC, the motor was limiting my motor power at up like 220W, which is not bad since now the 40% SOC it is for sure a real lower SOC than 40%.

Now I need to fully implement the SOC Coulomb counting on our EasyDIY display, because the original SOC of M500 is totally wrong.

2. Walk assist does not work: I mean the motor rotates but at very slow speed like 2 km/h and has very low torque meaning that it even can not push at all the ebike on the hills, the motor just stops on the hills that is when I really need walk assist.

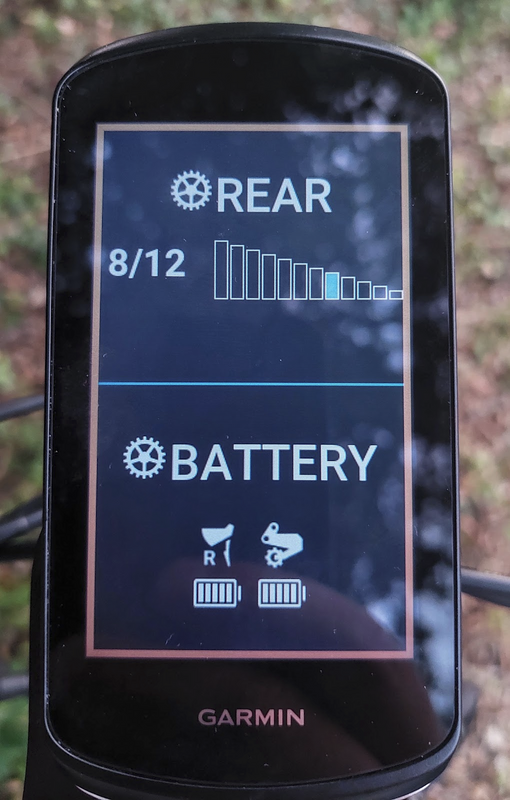

3. Electronics gears are perfect not related to this motors because they are modular (unlike the electronic gears just released by Shimano that only works for their electric motors), the SRAM AXS, worked flawlessly, perfectly, while my previous mechanical gears would always missing some gear and that was frustrating because I want to pedal as smooth as possible. The M500 works very well, so the external gears need to be on pair with the motor.