Hello girls and boys women and man.

I'm James Kapteijn and I live in the Netherlands at the moment. I'm following a bachelours degree in automotive engineering in Rotterdam.

Sinds I started my degree, electric bikes got my attention and have been planning for a first build for a long time now, but as a student the budget is small but I have a big passion to be succesfull in the first build. So I have been looking at this forum for a long time to learn stuff and creating idea's for my own build.

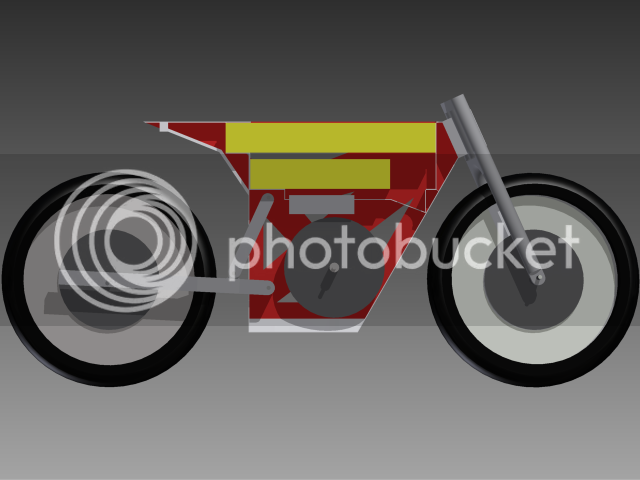

At the moment I'm designing a frame from scratch to house the following components:

- batterie (6s4p) 66.6 v 32 Ah pack

- 2 or 3 speed gearbox or hub from a mtb or nexus hub.

- Mid drive setup like cyclone,recumpence's system of a rc setup.

- Controller

- All the electronics for the the controller, handlebars and lights.

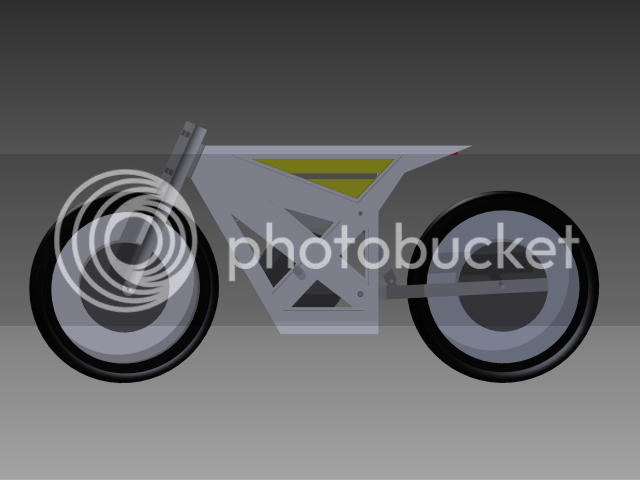

The base of the build will be the geometry of my current bike. This is a beone aspire 1.0. The frame size is precise wat I need to sit comfortable. 6 foot 6 is not the smallest of people. When I have the geometry in the computer I'll design it further. I dont like sketching because i like to work out the ideas straight away.

This weekend I'll measure the frame up and base my design from it.

Update 4/7/2013 New route continues from post 12.

continues from post 12.

I want to DIY because it's a good learning experience. And I know I'm al over the place and it's hard for u guys to keep track but by your comments I look in to things and having new ideas straight away. So my head is buzzing al the time and trying out new things and searching what I m looking for.

I have decided that I'll go the easy route with the drive train. I like the idea of the RC motor because it's easy to test and in the basics very easy I think (or could be wrong).Well the principals of every electric engine is the same but I hope you guys know what I mean. I read this http://endless-sphere.com/forums/viewtopic.php?f=28&t=28424 of fellow dutch person that made a friction drive on his bike. So that is a good indication what reduction is needed for this type of engine.

Well I think every body has it's own approach to his or her build so I ll go with a belt drive that attaches to the crank and from the crank to rear wheel with a rear derailleur 3 speed. I'll put it in the computer

Frame wise I'm still wanting to build my own but with a geometry with the pointers of Willow. and based on something existing.

Best regards,

James kapteijn

I'm James Kapteijn and I live in the Netherlands at the moment. I'm following a bachelours degree in automotive engineering in Rotterdam.

Sinds I started my degree, electric bikes got my attention and have been planning for a first build for a long time now, but as a student the budget is small but I have a big passion to be succesfull in the first build. So I have been looking at this forum for a long time to learn stuff and creating idea's for my own build.

At the moment I'm designing a frame from scratch to house the following components:

- batterie (6s4p) 66.6 v 32 Ah pack

- 2 or 3 speed gearbox or hub from a mtb or nexus hub.

- Mid drive setup like cyclone,recumpence's system of a rc setup.

- Controller

- All the electronics for the the controller, handlebars and lights.

The base of the build will be the geometry of my current bike. This is a beone aspire 1.0. The frame size is precise wat I need to sit comfortable. 6 foot 6 is not the smallest of people. When I have the geometry in the computer I'll design it further. I dont like sketching because i like to work out the ideas straight away.

This weekend I'll measure the frame up and base my design from it.

Update 4/7/2013 New route

I want to DIY because it's a good learning experience. And I know I'm al over the place and it's hard for u guys to keep track but by your comments I look in to things and having new ideas straight away. So my head is buzzing al the time and trying out new things and searching what I m looking for.

I have decided that I'll go the easy route with the drive train. I like the idea of the RC motor because it's easy to test and in the basics very easy I think (or could be wrong).Well the principals of every electric engine is the same but I hope you guys know what I mean. I read this http://endless-sphere.com/forums/viewtopic.php?f=28&t=28424 of fellow dutch person that made a friction drive on his bike. So that is a good indication what reduction is needed for this type of engine.

Well I think every body has it's own approach to his or her build so I ll go with a belt drive that attaches to the crank and from the crank to rear wheel with a rear derailleur 3 speed. I'll put it in the computer

Frame wise I'm still wanting to build my own but with a geometry with the pointers of Willow. and based on something existing.

Best regards,

James kapteijn