i have a "4"kw rear hub direct drive by ebikling, i suspect it actually a 3kw, 45h magnets 155mm dropout required.

i was chasing down a noise, when people hear it they ask if my bike is broken, but it still has full power

i suspected bad bearings, and i am pretty sure the bigger bearing that is on the brake side is bad, its not super smooth, i can feel inconsistent rolling and hear noises associated with the feel, if i spin the bearing by hand with the bearing removed from the hub.

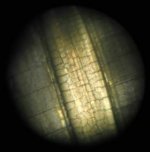

how ever, on the freewheel side of the motor, there is a side plate disk cover thing, and it is full of tiny cracks.

the cracks do not pass all the way through to the outside of the cover, they mostly seem to come from the reinforcement areas of the star shape thing that holds the bearing.

i do run what might be called high power, i run 66.6v 44ah lipo, but i normally only go about 30-35mph but for a solid 50 minutes to work and the noise gets worse as the ride continues, especially if am hard on the throttle. when i am the hardest on it, i will give it 120amps but only for a few seconds here and there. i did have issues with spokes, but i am using better spokes now i think.

could these cracks also be part of the noise i am hearing?

should i be concerned?

how did these cracks get there? abuse? weight? heat? poor design?

seems like i saw the cracks the first time i took it apart to glue the magnets back down, but i didnt pay attention to them

could i have put this back together wrong some how which lead to damage? seems like would be hard to do wrong. i use a big puller to gently take this thing apart.

if i need to get a new cover, where would i find one?

appreciate the input

i was chasing down a noise, when people hear it they ask if my bike is broken, but it still has full power

i suspected bad bearings, and i am pretty sure the bigger bearing that is on the brake side is bad, its not super smooth, i can feel inconsistent rolling and hear noises associated with the feel, if i spin the bearing by hand with the bearing removed from the hub.

how ever, on the freewheel side of the motor, there is a side plate disk cover thing, and it is full of tiny cracks.

the cracks do not pass all the way through to the outside of the cover, they mostly seem to come from the reinforcement areas of the star shape thing that holds the bearing.

i do run what might be called high power, i run 66.6v 44ah lipo, but i normally only go about 30-35mph but for a solid 50 minutes to work and the noise gets worse as the ride continues, especially if am hard on the throttle. when i am the hardest on it, i will give it 120amps but only for a few seconds here and there. i did have issues with spokes, but i am using better spokes now i think.

could these cracks also be part of the noise i am hearing?

should i be concerned?

how did these cracks get there? abuse? weight? heat? poor design?

seems like i saw the cracks the first time i took it apart to glue the magnets back down, but i didnt pay attention to them

could i have put this back together wrong some how which lead to damage? seems like would be hard to do wrong. i use a big puller to gently take this thing apart.

if i need to get a new cover, where would i find one?

appreciate the input