NeilP

1 GW

I thought I'd start a new thread on this...as the old previous thread is not so descriptive.

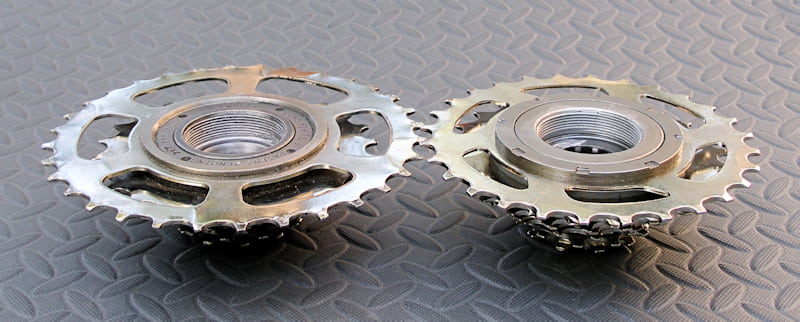

I bought a New 11-28 DNP Epoch freewheel

but the back end is sticks out a bit more, so the unit is wider as per this pic

The one on the left is a 11-32 I think.

All the threads on these are standard threads, so they undo in the normal fashion...anticlockwise.

If you do not have a Long reach DNP Epoch removal tool, then by stripping the freewheel on the motor, you should be able to get all the cogs off, then the carrier..to enable you to use the standard tool..as the 'depth' disappears when the splined carrier comes off.

To unscrew the splined stepped carrier from the freewheel you would need to put a strap wrench around the back on the the collar that I ground away, and then turn on the splines.

View attachment 4

Here is the compete freewheel with just the small collar removed and all the sprockets taken off.

Take note that all the small ones are standard Cassette-style splines and are polarised...but the bigger 3 are not polarised

The freewheel unit seems to be a sealed unit...there are no cir clips or further indications that anything else will unscrew. WRONG. I STRIPPED IT. SEE FURTHER DOWN THE THREAD...it is just those two dimples that look very much like spot-welded pins or similar...either way, opening it is likely to be a one-way process

This last pic is where I took too much metal off the back.

Go back up and look at the first picture, and then back to this one, you will see an extra 'ring', this is the race that holds the balls for the bearing in place...I exposed it all by grinding too much metal away from the back.

The groove cut through is just so I could see a profile of the unit, and where I realised that the rear outer ring, on the backside, was in fact not a retaining ring. I assumed it was a ring screwed to a protruding section of the splined body, but cutting through it showed the truth, that it was part of the inner section, the ratchet mechanisim.

I bought a New 11-28 DNP Epoch freewheel

but the back end is sticks out a bit more, so the unit is wider as per this pic

The one on the left is a 11-32 I think.

All the threads on these are standard threads, so they undo in the normal fashion...anticlockwise.

If you do not have a Long reach DNP Epoch removal tool, then by stripping the freewheel on the motor, you should be able to get all the cogs off, then the carrier..to enable you to use the standard tool..as the 'depth' disappears when the splined carrier comes off.

To unscrew the splined stepped carrier from the freewheel you would need to put a strap wrench around the back on the the collar that I ground away, and then turn on the splines.

View attachment 4

Here is the compete freewheel with just the small collar removed and all the sprockets taken off.

Take note that all the small ones are standard Cassette-style splines and are polarised...but the bigger 3 are not polarised

The freewheel unit seems to be a sealed unit...there are no cir clips or further indications that anything else will unscrew. WRONG. I STRIPPED IT. SEE FURTHER DOWN THE THREAD...it is just those two dimples that look very much like spot-welded pins or similar...either way, opening it is likely to be a one-way process

This last pic is where I took too much metal off the back.

Go back up and look at the first picture, and then back to this one, you will see an extra 'ring', this is the race that holds the balls for the bearing in place...I exposed it all by grinding too much metal away from the back.

The groove cut through is just so I could see a profile of the unit, and where I realised that the rear outer ring, on the backside, was in fact not a retaining ring. I assumed it was a ring screwed to a protruding section of the splined body, but cutting through it showed the truth, that it was part of the inner section, the ratchet mechanisim.