jimmyhackers said:

his only concern (not one in my mind) is that the spokes and rim arent up to par.

Most of the kit rims I've seen and owned are inadequate for the spoke gauge used; typically they use 12g spokes on the cheapest bicycle rims they can get, so the rims are not strong enough to hold the spoke tension even under normal usage. (and they generally don't come properly tensioned to start with).

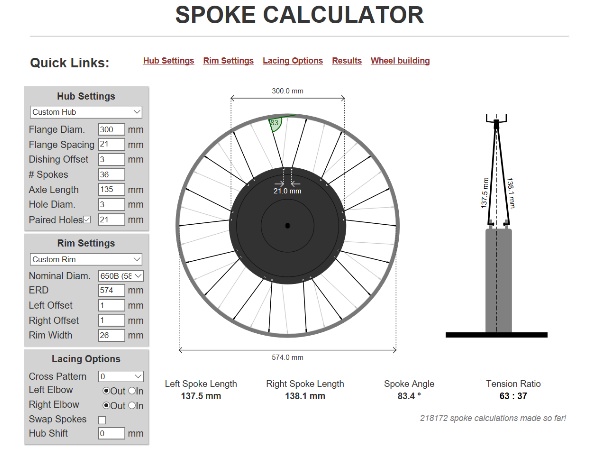

So...I doubt that it would handle bashing wihtout a rebuild, at the least using thinner spokes the rim can actually handle at the correct tension. Might want to buy just the motor, and a good rim designed for such bashing, then use spokes designed for that rim (probably 14g-15g butted or double butted would work best).

I've broken spokes, on those with just normal usage. Worse, the rims themselves cracked around the nipple holes from the tension required to tighten the spokes enough to have a usable wheel, and so the spokes would get loose, requiring more tension, making the rim worse, etc.

ive had my hub motor for over 2 years with no problem, but he doesn't see this as a good enough sample size, as i weigh 12 stone instead of his 14-15stone.

It's not just the weight, it's the usage. (smooth roads vs impacts) ON smooth roads the weight won't really matter much, but the worse the bump the more the weigth matters (mass x velocity).

For instance, SB Cruiser with me on it weighs something like 500lbs. The wheels on it are quite strong, I built them well. They handle most stuff fine, and the weight doesn't cause any problems by itself.

But...deep potholes with sharp edges where large chunks of pavement are completley missing are another thing entirely. I've destroyed one rim (wiht zero spoke damage) crushing the edge of the rim where the tire bead seats; it actually would've been "ok" but I bent it back, and that made it split and eventually spread across the rim further and further.

The second rim this happened to is actually still working fine (as are it's spokes), since I didn't try to fix the bend, although it's bent enough to be untruable (no rim brakes so doesn't really matter that much).

Heck, I even hauled an upright piano (800lbs? more? Dunno) on a trailer built with two sets of paired ("duallie") regular 26" bicycle wheels for several miles, and they handled it fine, but I also specifically avoided all the nonsmooth surfaces that I could, and kept speed down so that any holes I did hit would have much less impact velocity / energy. (it's also been used to haul several hundred pounds of dog food, wiht just two wheels, under similar conditions)

The spokes on SB Cruiser's rear wheels are short (70-80mm? Cant' remember) and 13g-14g butted. Radially laced due to the rim size vs motor diameter. THe rims are wide 20" rims, originally from a very early Zero Motorcycle design, IIRC, one that was more built along the lines of a high power bicycle than motorcycle. and I'm using 16" x 2.5" moped/mc tires (shinko sr714) for puncutre resistance and wear life, as well as the extra cushion of the larger tire (they're much bigger than "2.5"" bicycle tires would be) at the lower pressure they use.

I could probably have used 14-15g butted just as well.