ProgramThyself

100 mW

- Joined

- May 20, 2019

- Messages

- 38

I want to get started with customizable FOC for a 36V/500W front hub motor (Q100 type). My goal is working traction control and I'm leaning towards monitoring the "speed observer" in an FOC algorithm and reducing the torque when acceleration is high. What is a good system that would allow me to focus on software and physics with minimal soldering?

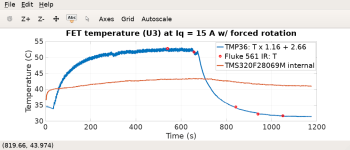

For $104 total, I'm close to pulling the trigger on the Texas Instruments eval boards LAUNCHXL-F280069M (CPU) and BOOSTXL-DRV8323RS (54V, 15A power stage). Having worked with TI MCUs elsewhere, I'm weary of the mess they've made on the software and documentation side. VESC 4 controllers are available for a similar price, but jumping into the VESC code looks like a deeper pool than TI, which has various "lab" modules to teach about their FOC library.

FOC Development Boards were discussed years ago with TI getting the most attention, but I wonder if anyone has recent experience, as this area of technology has matured (or at least become more accessible)?

For $104 total, I'm close to pulling the trigger on the Texas Instruments eval boards LAUNCHXL-F280069M (CPU) and BOOSTXL-DRV8323RS (54V, 15A power stage). Having worked with TI MCUs elsewhere, I'm weary of the mess they've made on the software and documentation side. VESC 4 controllers are available for a similar price, but jumping into the VESC code looks like a deeper pool than TI, which has various "lab" modules to teach about their FOC library.

FOC Development Boards were discussed years ago with TI getting the most attention, but I wonder if anyone has recent experience, as this area of technology has matured (or at least become more accessible)?