ardillo lambo

10 mW

- Joined

- Feb 21, 2020

- Messages

- 21

Folks,

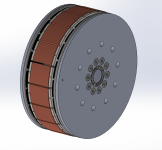

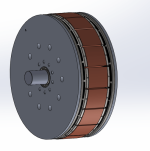

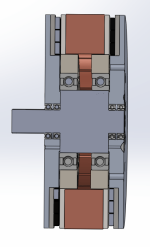

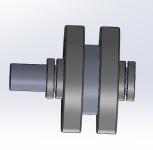

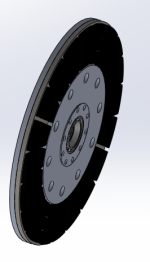

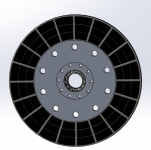

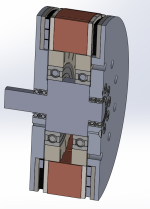

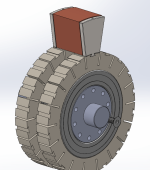

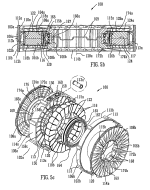

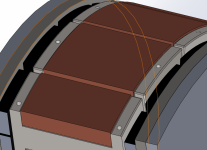

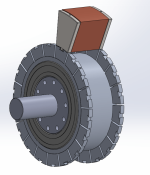

I'm planning converting a sports motorcycle (2004 Yamaha R1). As part of the project, would like to design and build my own motor. After some research, would like to go with a YASA type motor. Not too much information available out there on how to calculate some of the electrical characteristics. I already did the mechanical design in solid works for the stator, rotor disks and shaft, just as a starting point. some of the dimensions are based on documents found during the research. Those dimensions can be modified as needed to satisfy the performance criteria below:

75 kW continuous power

150 kW peak power(1 min)

80 N.m continuous torque

160 N.m peak torque (1 min)

6,500-7,000 RPM

470 nominal DC voltage (for controller)

3 phase

18 magnet poles

20 coils

I was wondering if any of you guys can point me in the right direction on how to calculate/determine some of the electrical characteristics.

will be posting some screen shots for the mechanical design in a few days.

Regards,

I'm planning converting a sports motorcycle (2004 Yamaha R1). As part of the project, would like to design and build my own motor. After some research, would like to go with a YASA type motor. Not too much information available out there on how to calculate some of the electrical characteristics. I already did the mechanical design in solid works for the stator, rotor disks and shaft, just as a starting point. some of the dimensions are based on documents found during the research. Those dimensions can be modified as needed to satisfy the performance criteria below:

75 kW continuous power

150 kW peak power(1 min)

80 N.m continuous torque

160 N.m peak torque (1 min)

6,500-7,000 RPM

470 nominal DC voltage (for controller)

3 phase

18 magnet poles

20 coils

I was wondering if any of you guys can point me in the right direction on how to calculate/determine some of the electrical characteristics.

will be posting some screen shots for the mechanical design in a few days.

Regards,