Can someone please explain this to me?

http://www.freeflowtechnologies.com/about-us/

http://www.freeflowtechnologies.com/about-us/

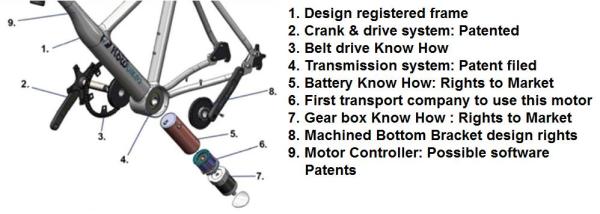

FreeFlow Technologies is a company that supplies innovative products and solutions for the transport and leisure market place.

The main difference with our technology is that it looks at Newtons second law F=ma in a different light to how all other transport excluding aviation have looked at it before. In that within bikes, cars, trucks… even conveyor belt motors use a reasonably heavy mass with a slow acceleration (that we can control) to give the right amount of force on to the drive system.

While our way of thinking is why not use high acceleration and low mass to give the same force on to the drive system. The reason this has not been done in ground based transport is if you have to suddenly stop, thus instantly putting force back through the drive system causing the motor to stop spinning and the motor does not have enough mass to absorb the sudden inertia it blows up. That is where our Patent published transmission system comes in, when the force from the motor goes through the drive shaft and in turn our transmission system. It is mechanically impossible for the Force to travel back on to the drive shaft, thus instantly decoupling the motor and allowing it time to slow down on its own accord.

When our technology is applied to a e-bike our system automatically calculates the vehicle and user weight allowing the user to input any cargo weight. Then we use other sensors to work out if you are on the flat, incline, decline, if the cranks are turning forward and at what speed, the gear you are in and the speed from the wheel. We then process the collective information real time allowing us to work out the correct acceleration to apply to the mass to give the correct force on to the drive shaft.

Why is this important it is important because it should take a different amount of energy to get a 75Kg rider to the top of a 100ft hill with a 1:3 incline than it takes to get a 100Kg rider. With our system we take the correct amount of power to spin the motor at very high speeds however increase that speed (thus draw more energy to spin the motor faster) for heavier riders making a lighter rider be able to go further as they will pull less energy from the battery.