Hey guys.

I'm starting a project that is going to require a high-torque, low-speed motor because I'm running a ~30 inch diameter tire.

To throw some numbers out, I'm looking for:

~100+ lb-ft of peak torque. (135 Nm) (90 lbs thrust)

~3000W of peak (motor) power.

~400 RPM (unloaded speed = ~35 MPH for my ~30" diameter tire application)

Justin suggested the GMAC 10T (clutchless grin-special), I may go with that in the end but I have a rightful fear of gears for my application. So I'd rather find a DD motor...

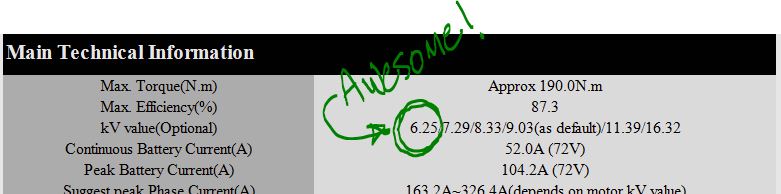

I thought I found the perfect motor:

QS 205 50H V3 3000W Hub Motor w/ a 6.25 Kv winding.

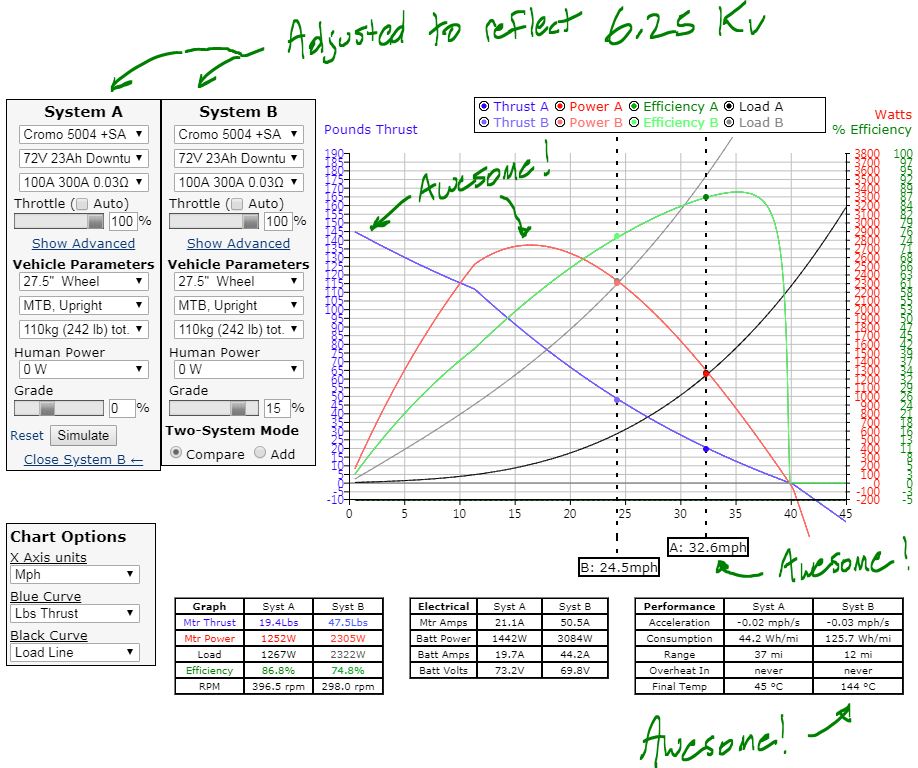

Here's the Grin Simulation showing it can eat 15% grade hills all day long (Cromo 5004 w/ KV adjusted accordingly):

https://www.ebikes.ca/tools/simulat...in&mass_b=110&hp_b=0&grade_b=15&k_b=.67&k=.67

That's a lot of awesome.

Only problem is:

According to a QS sales-rep:

QS doesn't actually make any of their 205 motors with anything less than 9.03 Kv.

(despite what it says on their website)

So, the quest for the illusive high-torque, low-speed hub motor continues...

Any suggestions?

Thanks.

-Josh!

I'm starting a project that is going to require a high-torque, low-speed motor because I'm running a ~30 inch diameter tire.

To throw some numbers out, I'm looking for:

~100+ lb-ft of peak torque. (135 Nm) (90 lbs thrust)

~3000W of peak (motor) power.

~400 RPM (unloaded speed = ~35 MPH for my ~30" diameter tire application)

Justin suggested the GMAC 10T (clutchless grin-special), I may go with that in the end but I have a rightful fear of gears for my application. So I'd rather find a DD motor...

I thought I found the perfect motor:

QS 205 50H V3 3000W Hub Motor w/ a 6.25 Kv winding.

Here's the Grin Simulation showing it can eat 15% grade hills all day long (Cromo 5004 w/ KV adjusted accordingly):

https://www.ebikes.ca/tools/simulat...in&mass_b=110&hp_b=0&grade_b=15&k_b=.67&k=.67

That's a lot of awesome.

Only problem is:

According to a QS sales-rep:

QS doesn't actually make any of their 205 motors with anything less than 9.03 Kv.

(despite what it says on their website)

So, the quest for the illusive high-torque, low-speed hub motor continues...

Any suggestions?

Thanks.

-Josh!