Has anyone tried to use thyristors to replace contactors ? I have some beefy ones capable of 150A, but not sure what the best approach would be to implement the "off" circuitry.

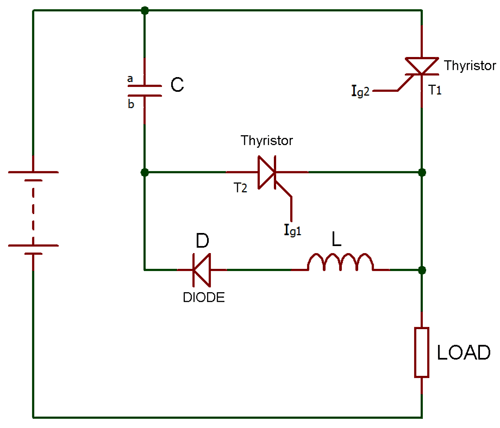

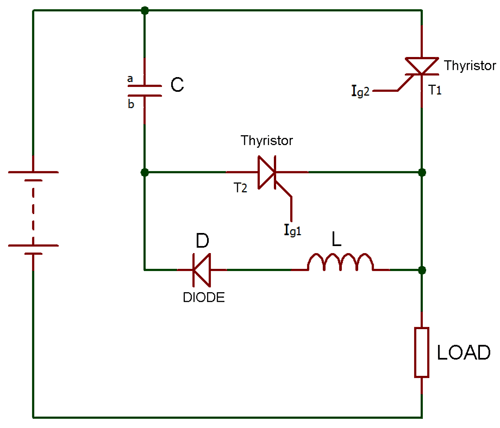

This looks safe, but requires two thyristors :

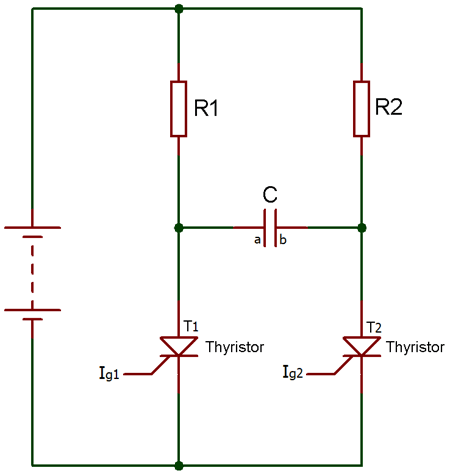

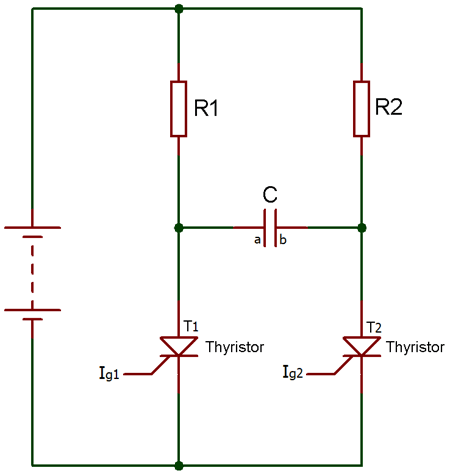

Then there is this, same deal :

More here :

https://www.electronicshub.org/scr-turn-off-methods/

This looks safe, but requires two thyristors :

Then there is this, same deal :

More here :

https://www.electronicshub.org/scr-turn-off-methods/