Hi guys,

As I'm new in this forum don't hesitate to correct mi if I do something wrong about the presentation etc.

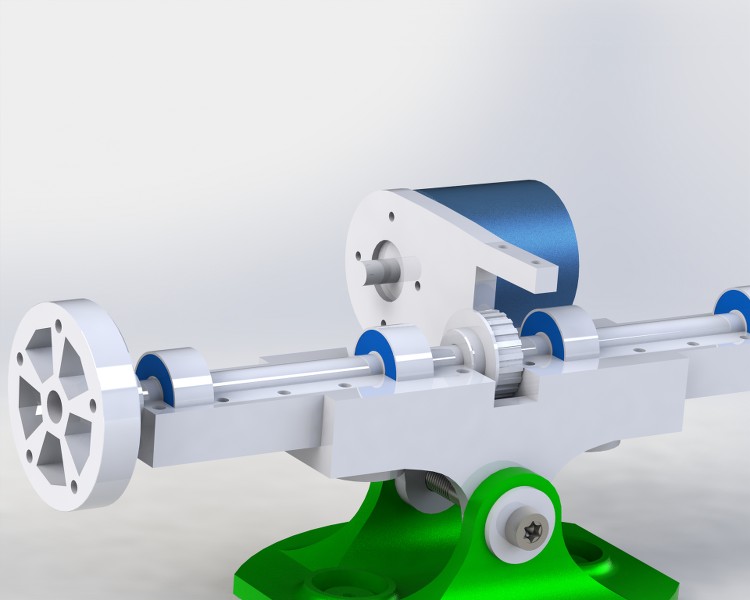

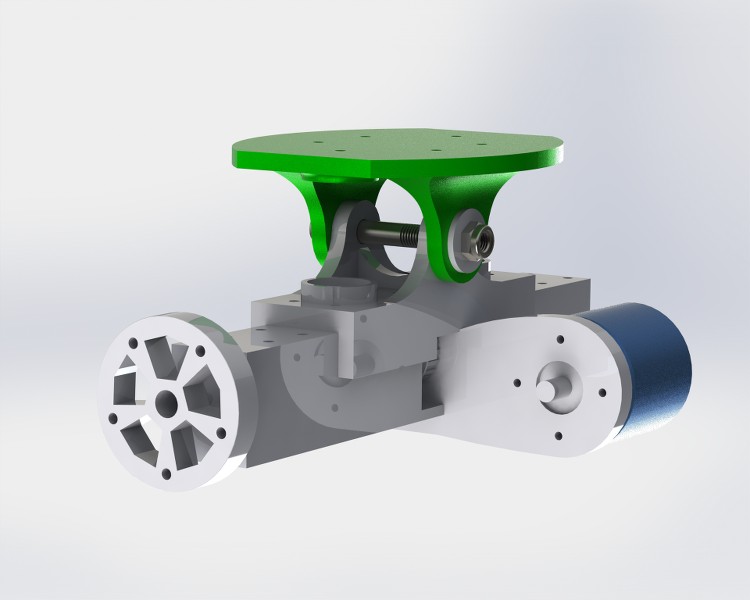

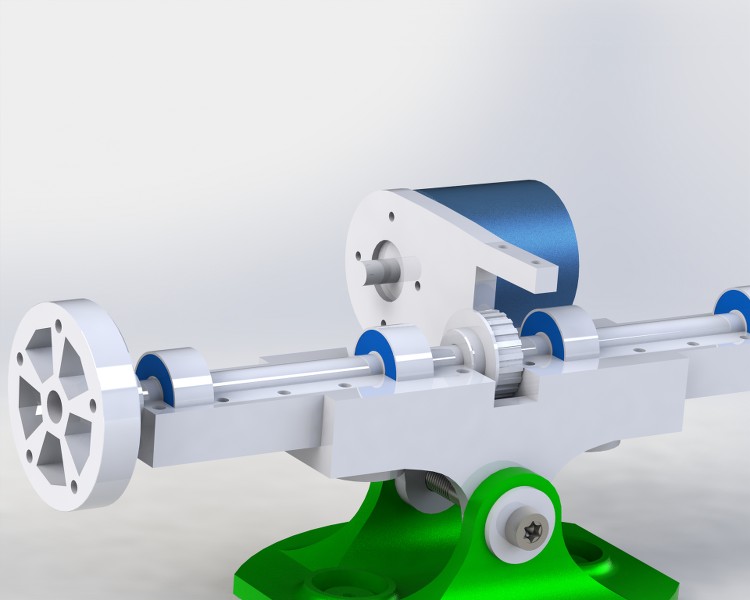

So now let me explain you my project, I'm working on a mountainboard truck that would have one motor to make the two wheels turn.

To do this im planning to remake the lower section of an MBS Matrix truck with a shaft in the middle.

The motor I want to use is the 6374 with the controller from Alien Power systems, I will also use his 10S 10Ah Lipo Pack with BMS.

So now let me show you where I am on the project:

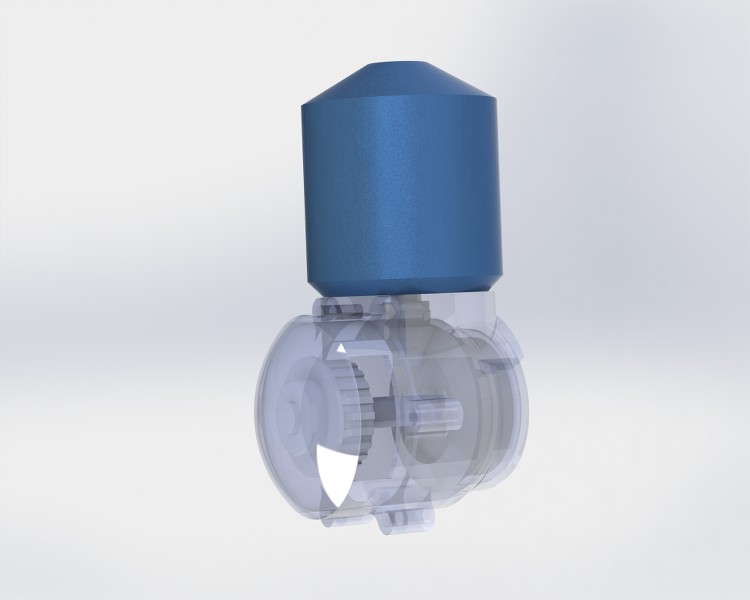

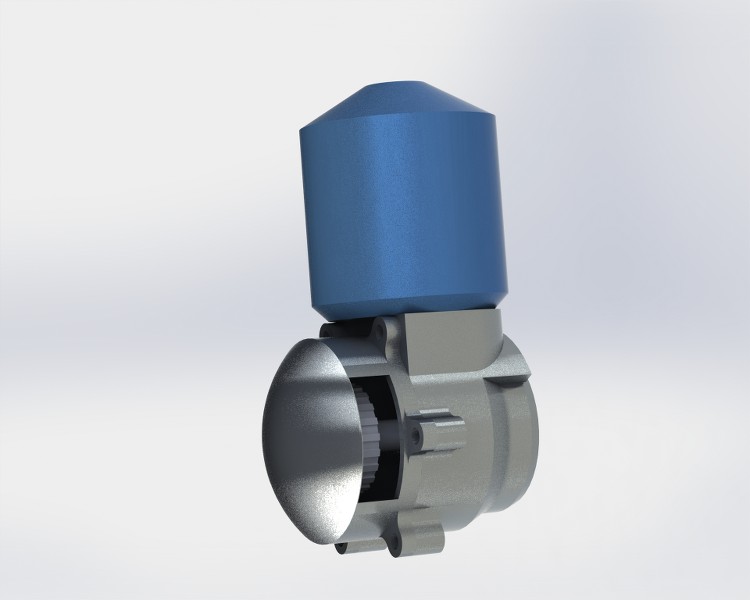

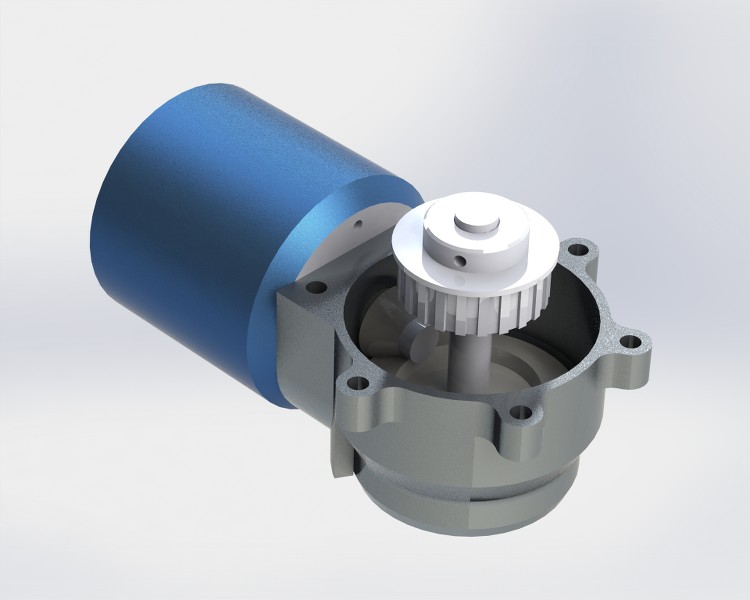

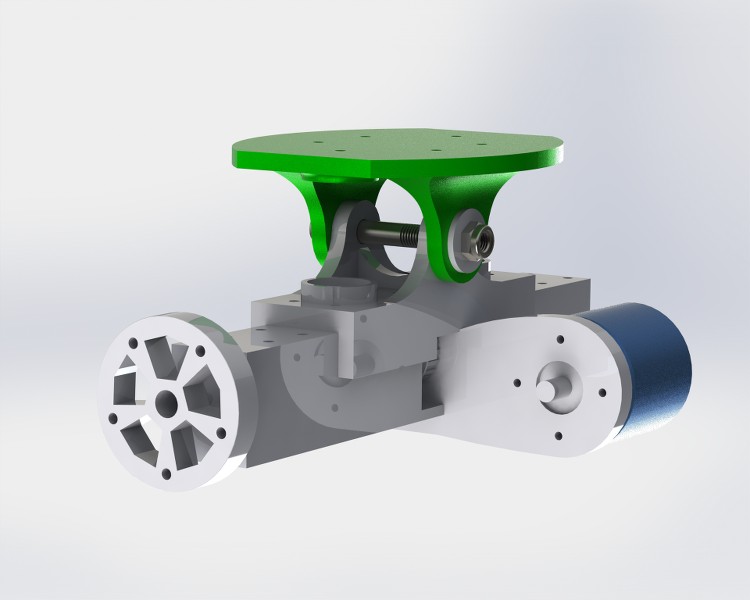

This would be the prototype looks bulky but doesn't need to be pretty since it is only a prototype.

The bottom part (in green) Is only for the reference as I will use the plastic one from the MBS Matrix.

All the parts except for the axle will be made out of 6061 T6 Aluminum. The axle itself will be in hardened steel with 12mm diameter ( dont yet know what type of steel I still have to talk about it with the one wo will make it for me)

The wheels are 8" Kheo Kicker wheels that where on my mountainboard and i will use the existing holes to mount the plate that connects them to the axle.

In the inside part im planning to use 4 "5201-2RS" bearings and a belt drive system.

I still have to wait a bit to get my cnc mill to start to build so I have some time to think about it.

Now i need some opinion, do you think it would hold with all the vibration and bumps it will take? or should i stop right now and find an other solution?

As I'm new in this forum don't hesitate to correct mi if I do something wrong about the presentation etc.

So now let me explain you my project, I'm working on a mountainboard truck that would have one motor to make the two wheels turn.

To do this im planning to remake the lower section of an MBS Matrix truck with a shaft in the middle.

The motor I want to use is the 6374 with the controller from Alien Power systems, I will also use his 10S 10Ah Lipo Pack with BMS.

So now let me show you where I am on the project:

This would be the prototype looks bulky but doesn't need to be pretty since it is only a prototype.

The bottom part (in green) Is only for the reference as I will use the plastic one from the MBS Matrix.

All the parts except for the axle will be made out of 6061 T6 Aluminum. The axle itself will be in hardened steel with 12mm diameter ( dont yet know what type of steel I still have to talk about it with the one wo will make it for me)

The wheels are 8" Kheo Kicker wheels that where on my mountainboard and i will use the existing holes to mount the plate that connects them to the axle.

In the inside part im planning to use 4 "5201-2RS" bearings and a belt drive system.

I still have to wait a bit to get my cnc mill to start to build so I have some time to think about it.

Now i need some opinion, do you think it would hold with all the vibration and bumps it will take? or should i stop right now and find an other solution?