EVGator

10 mW

Ok, I know this sounds crazy but hear me out? I want to lace a generic 1000W hub motor into a cheap chinese folding bike front wheel.

Why you ask? For the same reason that some jackass would put an LS motor in a Yugo. Is it a bad idea? Yes. Inherently risky? Yes. Is that part of the reason that I am doing it? Yes. I know it is a bad idea, and I know that I will have to beef up the front forks which are luckily made of steel. I have plenty of electrical and mechanical experience. What I don't have, is wheel building experience and the breadth of knowledge associated with it. I know that several of you on this forum do have that knowledge, and I would love some input as to how to make this a reality. I've attached some pictures of the 20" folding bike wheel assembly. I see the wheels often referred to as 20" despite the rim size being 16". Is that correct to say? This would be a 20" 406 wheel?

Some specs:

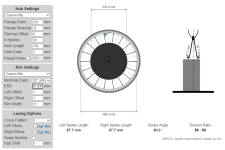

I am attempting to use Grin's spoke calculator to determine the spoke length that I will need, which can be found here: https://ebikes.ca/tools/spoke-calc.html. Does anyone have a better way to do this?

I don't have all of the info to fill out the spoke calculator yet. ERD, Offsets, Cross pattern (0, 1, 2?), Nominal Diameter (20" 406 I think?) still need to be determined/measured. Then, should I invest in a spoke threading tool set and cut the longer spokes to the length that I need?

I've got plenty of research ahead of me, but any feedback you guys can give will be greatly appreciated. I'll even make a sweet video of the shear torque ripping the front end off of the bike. The goal is to try prevent that from happening, but it's not outside the realm of possibility. Some of you will instantly shoot this idea down, but maybe someone with an open mind will see this as comical enough to lend a thought or two towards it.

Why you ask? For the same reason that some jackass would put an LS motor in a Yugo. Is it a bad idea? Yes. Inherently risky? Yes. Is that part of the reason that I am doing it? Yes. I know it is a bad idea, and I know that I will have to beef up the front forks which are luckily made of steel. I have plenty of electrical and mechanical experience. What I don't have, is wheel building experience and the breadth of knowledge associated with it. I know that several of you on this forum do have that knowledge, and I would love some input as to how to make this a reality. I've attached some pictures of the 20" folding bike wheel assembly. I see the wheels often referred to as 20" despite the rim size being 16". Is that correct to say? This would be a 20" 406 wheel?

Some specs:

- 20" x 1.75 tire on what looks to be a 16" rim

- 1000W motor which is currently laced into a 26" wheel

- 14 gauge (2.0mm) spoke size on the 20" wheel

- 12 gauge (2.6mm) spoke size on the hub motor

- Bike rim has 28 spoke holes

- Motor has 36 spoke holes

- Bike front dropout width is 100mm

- Motor dropout width is 100mm

- Motor axle length is 160mm

I am attempting to use Grin's spoke calculator to determine the spoke length that I will need, which can be found here: https://ebikes.ca/tools/spoke-calc.html. Does anyone have a better way to do this?

I don't have all of the info to fill out the spoke calculator yet. ERD, Offsets, Cross pattern (0, 1, 2?), Nominal Diameter (20" 406 I think?) still need to be determined/measured. Then, should I invest in a spoke threading tool set and cut the longer spokes to the length that I need?

I've got plenty of research ahead of me, but any feedback you guys can give will be greatly appreciated. I'll even make a sweet video of the shear torque ripping the front end off of the bike. The goal is to try prevent that from happening, but it's not outside the realm of possibility. Some of you will instantly shoot this idea down, but maybe someone with an open mind will see this as comical enough to lend a thought or two towards it.