Cricket_Swe said:

So how exactly did you manage to modify the dropout spacer?

Hey have a look at what i did with my wheel:

\\ (•◡•) / said:

Also good news I got my motor wire issue sorted!

infact it actually has room to spare, so really happy with that (Thank-you to all the people who gave me help and passed me forward to the other thread)

don't have any pics of the actual motor wire clearance on the frame yet but I promise to post some once I take them (probably when the bike is done in a week or two)

for now here's a teaser:

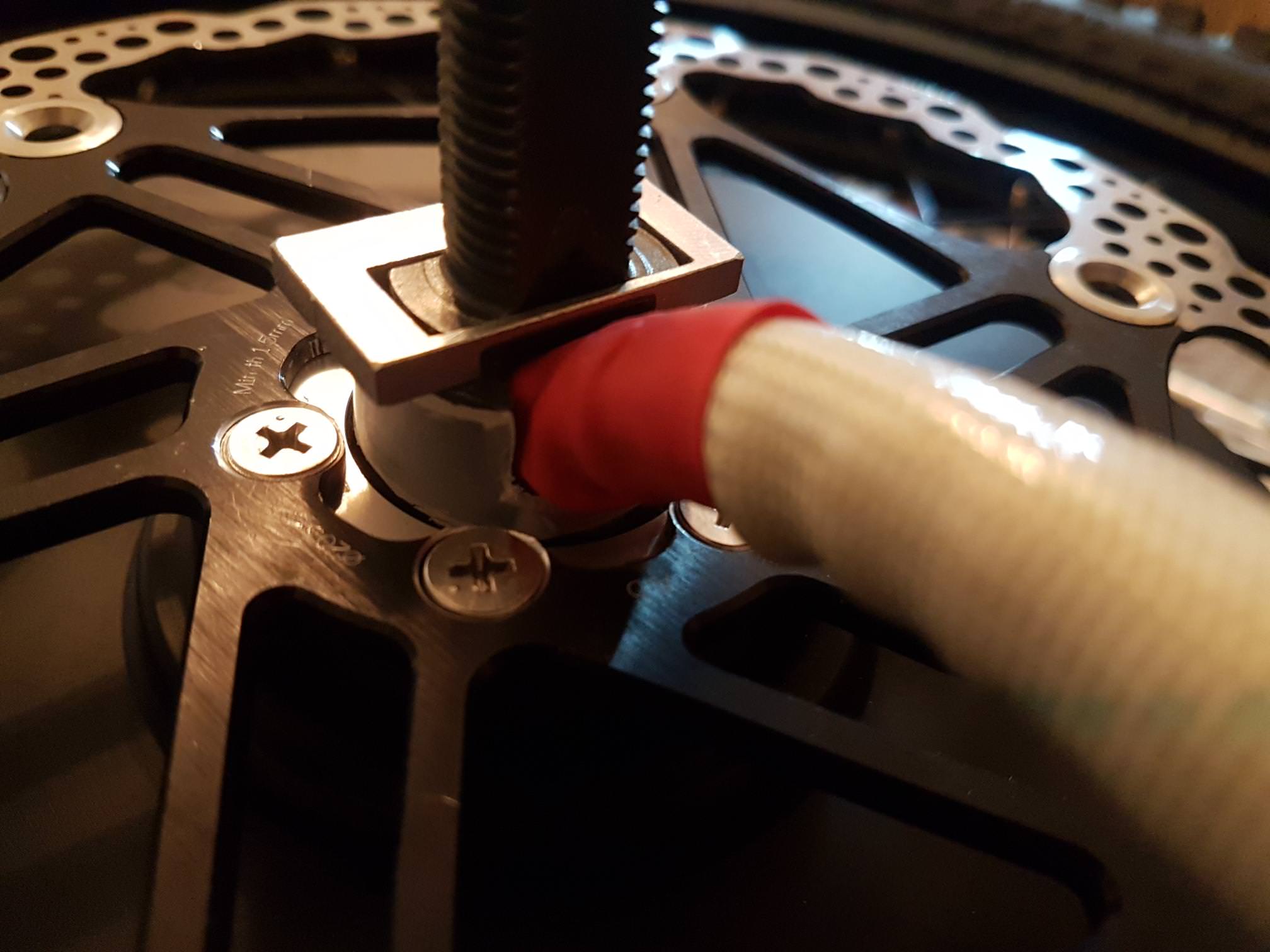

the plate you can see is a 4mm water-jet cut aluminium spacer with a milled slot. this spaces the dropout out a bit more giving the motor wire a great little home. it's funny actually because my dropout would originally sit maby 3 or 4mm out from my motor naturally and would then compress onto the motor when I tightened the nuts, but now it fits perfectly. I think whoever made my frame knew I was going to put in a QS 205 and was rooting for me. Anyway cyas later (for now)

Oh yea, and, I also have some really neat torque arms being made out of either D2 tooling steel or standard has strength steel ATM. will share photo's of that in a few days

seems I was in your exact shoes a while ago, I too run a qs 205 with hope tech 3 v4's and hope 203mm rotors on my alpha. also just to let you know I have my motor on my frame with the same combo as you and everything fits with lots of room, the motor wires arn't even close to the disk and the brake has lots of room from scraping the motor, so just know it can be done. also don't use as many rotor spacers as shown by allex on the bomber (the bomber has wider dropouts and smaller wires, so need to move the rotor out to the brake with spacers), as I said I use the same combo as your attempting so luckily you should be able to follow this guide and skip my trial and error process:

1) buy 1x 2mm hope spacer http://www.chainreactioncycles.com/hope-rotor-spacer/rp-prod3288 (only use 1x 2mm, the less rotor spacers you use the less your rotor will be pushed out into your phase wires). With 2mm spacer your brake will have enough room before it scrapes the side of your motor and will also keep your rotor in enough that you will have enough space to route your wires. You may also see that after using a 2mm spacer that you could even go with 1mm before your brake caliper will scrape your motor esentially giving you an extra mm of clearance for your wires, but don't because unforchantly with the hope rotors where there recessed at the back there diameter of the recession is smaller than the diamater of the extending circle mounting point on the qs205, so anything less than a 2mm rotor spacer and your rotor will only make contact to the mounting point of the qs205 with roughly only the outside 2mm of the rotor touching, so not a great idea.

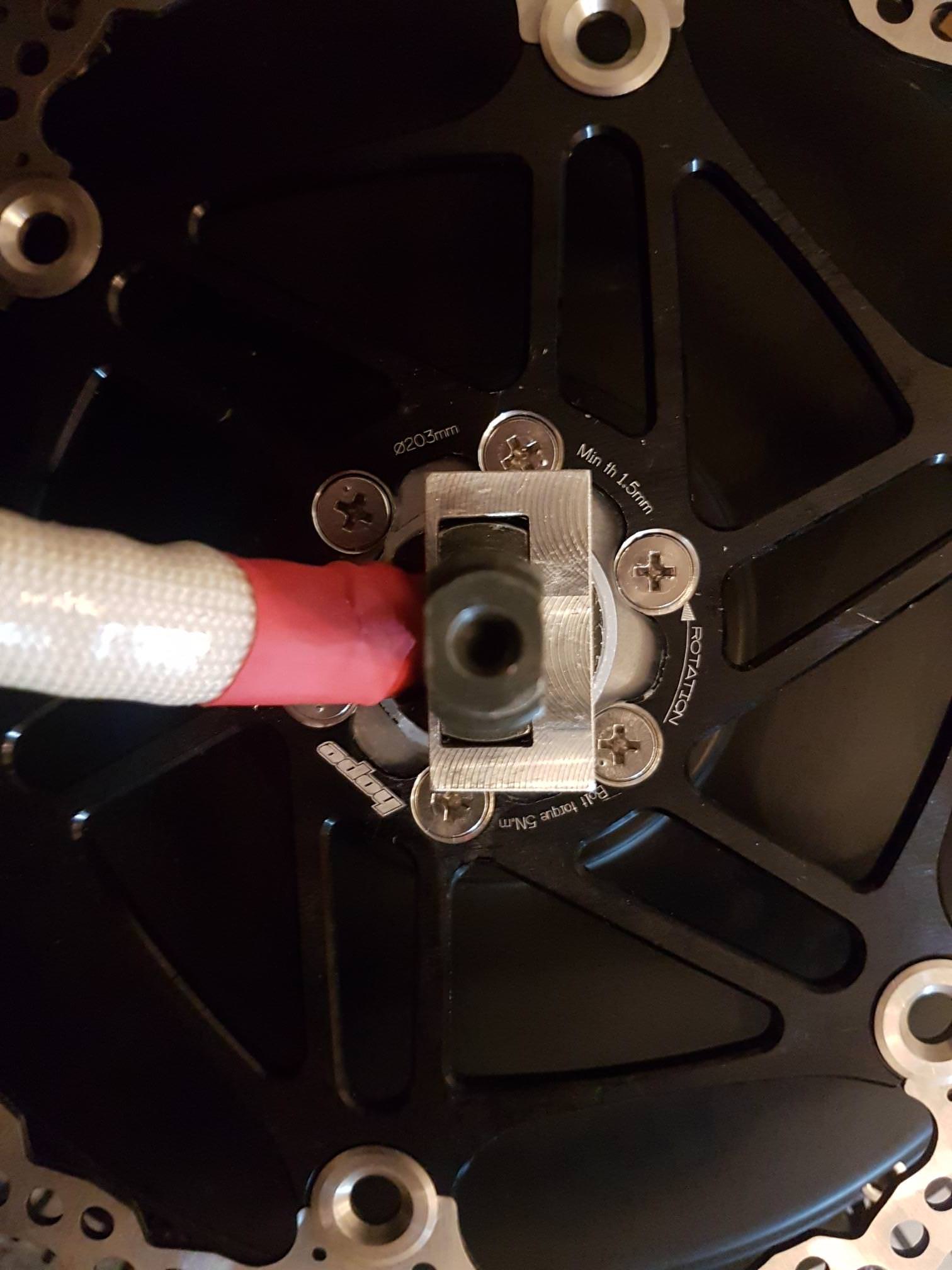

2) countersink your disk bolt holes and use countersunk hardware, this alone will give you a lot more room

3) (optional, I did it but it isn't strictly necessary, you can get away without doing it, but it's recommended) you can remove the wires for the spare set of hall sensors in your qs205 to make the wire bundle thinner (just snip the wires to your spare set of sensors, you'll see the wires are bundled up in the middle of the motor, just snip all the spare set wires and pull the 6 wires out of the wire bundle making it thinner, and if your main hall sensors ever die in the future you can just open you motor back up, cut your main hall wires and solder them only the wires coming out of your secondary sensor set)

4) basically you have to do this.... well not really but it will give your wires tonnes of space from the rotor, as you can see in my earlier photos on my motor shaft: get a plate cut that slides perfectly onto your axel, this will act like a spacer, spacing your swingarm away from your rotor giving your wires more space, my dropouts on my alpha were actually a touch wide originally and when I put the spacer in it actually ended up being perfect for my dropouts, but even if yours isn't a touch wide by default the dropouts are preety flexy and can just be pulled out with one hand when putting the motor in, doesnt take much force at all and since the frame is make of cromoly it's not gonna damage it, especially since it's widening it by proberbly only a couple degress of angle. (my spacer was custom milled down to 3.7mm of thickness, but 4mm will work perfectly aswell)

5) jeez this is becoming a little long... almost done though. make a shield so your wire can't possibly touch the rotor, i stole this idea from 'ridethelightning' in this thread https://endless-sphere.com/forums/viewtopic.php?f=6&t=62650&start=225#top to give credit (if you're reading this lightning, thanks man

), bascially buy a door stop like this: https://www.bunnings.com.au/adoored-100mm-white-cushion-door-stop_p3961376 , take out the inside part, saw off the pack and push/tap it onto your motor shaft with a mallet and a block of wood, then cut out the part for your wire, once again you can see this in the photos of my motor.

anyway thats all I can think of atm, it's a bit of a process but the futr alpha, qs205 and hope brakes are a fucken killer combo

, so it'll be worth it, also to give credit where it is due basically all my ideas were stolen or replicated from this process in this thread: https://endless-sphere.com/forums/viewtopic.php?f=6&t=62650&start=225#top so look there for more detail, also ill post photos of my wheel in frame with how much wire space and space between rotor and motor i have with my 2mm rotor space and the custom 3.7mm space if I remember tomorrow.

cheers!

good luck