You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The BEST and FIRST Qulbix Raptor mid-drive build!

- Thread starter LightningRods

- Start date

LightningRods

1 MW

John Bozi

100 kW

tikivic said:Quick update.....made a chain guard.

Looks awesome, can't wait for ride reports especially commenting on sideways flex of this single pivot.

ElectricGod

10 MW

John Bozi said:tikivic said:Quick update.....made a chain guard.

Looks awesome, can't wait for ride reports especially commenting on sideways flex of this single pivot.

I seriously doubt there will be any at all. You have a nice ridgid triangle between the motor and the drop outs made of square tube. Anything forward of the swing arm pivot is irrelevant.

LR...I think I need one of those motor brackets!

LightningRods

1 MW

These simple mounts should have lots of applications. They will be available and won't be expensive.

I'm already planning other applications of this design.

I'm already planning other applications of this design.

ElectricGod

10 MW

LightningRods said:These simple mounts should have lots of applications. They will be available and won't be expensive.

I'm already planning other applications of this design.

This is a case of Mike strikes again and it's a win! Stuff breaks, but lets face it, the stuff you make is far better than anything else out there that's similar.

LightningRods

1 MW

That's very kind of you to say. My only claim is that I love what I do and that I make the best parts that I can. I don't sit still very long.

Speaking of which...

Speaking of which...

LightningRods

1 MW

I've started assembling my OTHER Qulbix mid drive. This one is a bottom bracket mount that drives through the chainwheel. Evolutionary rather than revolutionary.

The aluminum bracket attached to the normal steel BB bracket has multiple functions. The lug on the top is a mounting spot for a torque brace. The right upper bracket has had a similar lug for quite a while. Some bikes have an easy mounting place for the other end of the brace, others do not. This provides a perfectly located place. It's also a set distance from the upper bracket so I can offer premade braces as well. Another function is that it provides a place to mount a spring loaded DH roller to deal with the chain growth on the Qulbix. This tensioner also takes oscillations out of the return run of chain and guides it onto the chainwheel. The last feature of this bracket will be an upper chain guide. It's similar to a front derailleur except that it doesn't move and it's a composite of aluminum and high impact polyurethane. It will allow the final drive chain to run without rubbing unless the chain tries to jump the chainwheel. There won't be enough space for the chain to derail.

This bottom bracket drive will have all #219 chain reduction. I've designed primary and secondary stainless steel sprockets just for this application. The chainwheel assembly will be a matched 60T #219 driven and 34T 1/2" driver chainwheel. The bottom bracket freewheel will be a White Industries HD or UHD. Overall reduction will be reduced from the usual 30:1 down to 15:1.

My intention with this mid drive is to take the chainwheel drive as far as it can go. Almost all of these parts will be available as options or retrofit upgrades for my regular mid drives. Once I have these two drives completed I'll start on the companion multiple speed HD rear sprocket set.

The aluminum bracket attached to the normal steel BB bracket has multiple functions. The lug on the top is a mounting spot for a torque brace. The right upper bracket has had a similar lug for quite a while. Some bikes have an easy mounting place for the other end of the brace, others do not. This provides a perfectly located place. It's also a set distance from the upper bracket so I can offer premade braces as well. Another function is that it provides a place to mount a spring loaded DH roller to deal with the chain growth on the Qulbix. This tensioner also takes oscillations out of the return run of chain and guides it onto the chainwheel. The last feature of this bracket will be an upper chain guide. It's similar to a front derailleur except that it doesn't move and it's a composite of aluminum and high impact polyurethane. It will allow the final drive chain to run without rubbing unless the chain tries to jump the chainwheel. There won't be enough space for the chain to derail.

This bottom bracket drive will have all #219 chain reduction. I've designed primary and secondary stainless steel sprockets just for this application. The chainwheel assembly will be a matched 60T #219 driven and 34T 1/2" driver chainwheel. The bottom bracket freewheel will be a White Industries HD or UHD. Overall reduction will be reduced from the usual 30:1 down to 15:1.

My intention with this mid drive is to take the chainwheel drive as far as it can go. Almost all of these parts will be available as options or retrofit upgrades for my regular mid drives. Once I have these two drives completed I'll start on the companion multiple speed HD rear sprocket set.

Mammalian04

100 kW

Sweet!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

scorpionice

10 W

NICE...

ElectricGod

10 MW

I love the laser cut tractors in everything. LOL

Quokka

1 kW

Very nice work. Subd

LightningRods

1 MW

Thanks!

ElectricGod

10 MW

Sorry for using your thread like this Mike, but lots of people follow it so I figured it's a good spot and I want to help out your customers if possible.

Everyone,

If you can afford it, get on Ebay or Amazon and look at the green multistar packs from Turnigy. I don't know if I just got UBER lucky or what, but this is exactly what just happened for me. Last week I was perusing around looking for some large capacity LIPO packs for a Currie kick scooter I'm upgrading. I came across some 10,000 mah packs for a decent price ($80 a pack including shipping) on ebay. I contacted the seller and told them I wanted all 8 that they had for a negotiated price. Before we could complete the transaction one sold to someone else, but we negotiated it for $45 a pack including shipping. I know...huge price cut for all of them! Well then I asked the same seller about 16,000 or 20,000 mah packs and they had 10 16,000 packs arriving so we negotiated for all of them and I got all 10 of them for $74 each including shipping. Considering the price for the 10,000mah packs...not as good a deal, but still pretty reasonable. I was also talking to another seller on ebay about 10,000mah packs and last night we negotiated for 6 of the 15 packs he had for $40.79 each. Now I'm working another deal for 2 more packs at $30 each shipped. I don't know if the bottom is falling out of these packs or what, but damn...I just spent a load of money and got some really sweet deals on new LIPO packs. I received the original 7 packs Thursday night, and they are definitely new. They came in their individual boxes, inside a pink bubble wrap bag, with a small manual just like they come from an RC store. I know the 10C multistar packs are not the best packs on the planet, but the prices are really impressive so what's there to lose? I've been charging and load testing packs for the last 60 hours. So far all of them charge to 4.2 volts per cell and load testing them at 3C shows no signs of sagging and they all discharge to 3 volts per cell and right at or slightly over 10,000mah. I have a single pack that might have a weak cell. I'm load testing it for the second time right now to see if that's the case or not. When I say "weak cell" I just mean that the rest of the cells were still running at 3.3 to 3.5 volts and this one got down to 3 volts first. That's not really very "weak".

All I can say is make hay while the sun is shining because these prices wont last forever. I'm out of money or else I would still be buying packs!

Everyone,

If you can afford it, get on Ebay or Amazon and look at the green multistar packs from Turnigy. I don't know if I just got UBER lucky or what, but this is exactly what just happened for me. Last week I was perusing around looking for some large capacity LIPO packs for a Currie kick scooter I'm upgrading. I came across some 10,000 mah packs for a decent price ($80 a pack including shipping) on ebay. I contacted the seller and told them I wanted all 8 that they had for a negotiated price. Before we could complete the transaction one sold to someone else, but we negotiated it for $45 a pack including shipping. I know...huge price cut for all of them! Well then I asked the same seller about 16,000 or 20,000 mah packs and they had 10 16,000 packs arriving so we negotiated for all of them and I got all 10 of them for $74 each including shipping. Considering the price for the 10,000mah packs...not as good a deal, but still pretty reasonable. I was also talking to another seller on ebay about 10,000mah packs and last night we negotiated for 6 of the 15 packs he had for $40.79 each. Now I'm working another deal for 2 more packs at $30 each shipped. I don't know if the bottom is falling out of these packs or what, but damn...I just spent a load of money and got some really sweet deals on new LIPO packs. I received the original 7 packs Thursday night, and they are definitely new. They came in their individual boxes, inside a pink bubble wrap bag, with a small manual just like they come from an RC store. I know the 10C multistar packs are not the best packs on the planet, but the prices are really impressive so what's there to lose? I've been charging and load testing packs for the last 60 hours. So far all of them charge to 4.2 volts per cell and load testing them at 3C shows no signs of sagging and they all discharge to 3 volts per cell and right at or slightly over 10,000mah. I have a single pack that might have a weak cell. I'm load testing it for the second time right now to see if that's the case or not. When I say "weak cell" I just mean that the rest of the cells were still running at 3.3 to 3.5 volts and this one got down to 3 volts first. That's not really very "weak".

All I can say is make hay while the sun is shining because these prices wont last forever. I'm out of money or else I would still be buying packs!

recumpence

1 GW

ElectricGod said:Sorry for using your thread like this Mike, but lots of people follow it so I figured it's a good spot and I want to help out your customers if possible.

Everyone,

If you can afford it, get on Ebay or Amazon and look at the green multistar packs from Turnigy. I don't know if I just got UBER lucky or what, but this is exactly what just happened for me. Last week I was perusing around looking for some large capacity LIPO packs for a Currie kick scooter I'm upgrading. I came across some 10,000 mah packs for a decent price ($80 a pack including shipping) on ebay. I contacted the seller and told them I wanted all 8 that they had for a negotiated price. Before we could complete the transaction one sold to someone else, but we negotiated it for $45 a pack including shipping. I know...huge price cut for all of them! Well then I asked the same seller about 16,000 or 20,000 mah packs and they had 10 16,000 packs arriving so we negotiated for all of them and I got all 10 of them for $74 each including shipping. Considering the price for the 10,000mah packs...not as good a deal, but still pretty reasonable. I was also talking to another seller on ebay about 10,000mah packs and last night we negotiated for 6 of the 15 packs he had for $40.79 each. Now I'm working another deal for 2 more packs at $30 each shipped. I don't know if the bottom is falling out of these packs or what, but damn...I just spent a load of money and got some really sweet deals on new LIPO packs. I received the original 7 packs Thursday night, and they are definitely new. They came in their individual boxes, inside a pink bubble wrap bag, with a small manual just like they come from an RC store. I know the 10C multistar packs are not the best packs on the planet, but the prices are really impressive so what's there to lose? I've been charging and load testing packs for the last 60 hours. So far all of them charge to 4.2 volts per cell and load testing them at 3C shows no signs of sagging and they all discharge to 3 volts per cell and right at or slightly over 10,000mah. I have a single pack that might have a weak cell. I'm load testing it for the second time right now to see if that's the case or not. When I say "weak cell" I just mean that the rest of the cells were still running at 3.3 to 3.5 volts and this one got down to 3 volts first. That's not really very "weak".

All I can say is make hay while the sun is shining because these prices wont last forever. I'm out of money or else I would still be buying packs!

Yup, I did the same thing. I have a total of 100ah of 12s lipo multistar lipo goodness for $1,500.

Matt

Quokka

1 kW

What voltage battery and how many amp hours are planning to power this with? What do you estimate you speed and range to be at around 30-40mph. Interested to compare the differences in your mid drive vs the stats from my Q76R. I have a 20s 12P pack of sanyo GA's (72v 40amp hour) I get range of 120-140km at 40-60km/hr and top speed of 110km/hr using an adaptto with ovs at 3. Would really like to drop some weight from the bike if this kit works out

LightningRods

1 MW

I'd like to be able to give you accurate numbers but I simply don't have them yet. Multiple speed mid drives are far more energy efficient than direct drive hub motors. How much of that efficiency we'll give up by going to single speed is hard to say. I'm looking forward to comparing my single speed drives to my multiple speed chainwheel version. I think that both will have their advantages and disadvantages.

The battery pack that you have now should work great if you want to try the swingarm drive. Users have been running the Big Block at up to 84V. 72V is great for single speed because you have nearly 50% more rpm range to deal with than 48V.

Both drives should be completed this week. I had to take a break over the weekend to celebrate a family member's birthday.

The battery pack that you have now should work great if you want to try the swingarm drive. Users have been running the Big Block at up to 84V. 72V is great for single speed because you have nearly 50% more rpm range to deal with than 48V.

Both drives should be completed this week. I had to take a break over the weekend to celebrate a family member's birthday.

ElectricGod

10 MW

Quokka said:What voltage battery and how many amp hours are planning to power this with? What do you estimate you speed and range to be at around 30-40mph. Interested to compare the differences in your mid drive vs the stats from my Q76R. I have a 20s 12P pack of sanyo GA's (72v 40amp hour) I get range of 120-140km at 40-60km/hr and top speed of 110km/hr using an adaptto with ovs at 3. Would really like to drop some weight from the bike if this kit works out

I run my big block at 82 volts and I'm running with just a single gear. My top speed on level ground is 50mph. I'm not running it on a bike, but rather a kick scooter with 52" circumference tires so my gearing doesn't need to be anywhere close to what you have to do for a 26" bike wheel. I typically max out around 3500 watts which means the motor is pulling nice and hard and cars mostly can't accelerate as fast as me. Just this morning I was sitting at a light next to an Audi A4. He was in the outside lane so I took the inside lane knowing I was going to beat him across the intersection and be able to merge over into his lane to turn right a half block down. Sure enough, I left him in my dust and got over and turned right without him ever slowing down. Anyway, accelerating hard is usually about 40 amps draw with me standing up and creating the maximum amount of wind drag possible. If I accelerate hard and get down low on the scooter, current is a little lower, but IMHO negligibly so...just 2 amps. To me two amps is hardly worth mentioning, You would get similar results just climbing a minor hill compared to level ground. As far as efficiency is concerned, there are better motors out there, but they also cost lots more money. These motors are better than the uber cheap motors, but not as good as motor efficiency can be. They are better than average. by the way, I weight 240 pounds and my scooter weighs 120 pounds so this motor is hauling around 360 pounds and not breaking a sweat doing it. It typically runs at 120-140F on a hot summer day or 90-110F now that temps are in the 60s. I can't speak for other users of this motor and they run theirs through the bikes gearing so who knows what that add or subtracts from overall efficiency, I can only speak for how it runs for me on my ride. I would definitely buy another one and run it at even higher voltages. I'm currently building a moped and I intend to run it at 98 volts. I wouldn't be afraid to run the big block at that voltage. It definitely runs great at 82 volts.

LightningRods

1 MW

Great information! Thanks! I'm headed to the same place with the swingarm drive that you are with your scooters. I notice similar draws running around in one gear without shifting. It's hard to get the big motor to draw full amps unless you're going up a hill.

The swingarm drive is disassembled for paint. We're really just waiting on some new hardware in order to be able to finish both drives. It should be here any day.

I'm really pleased by all of the purchase enquiries regarding the swing arm drive. Don't worry I won't sell out of them. When I said that I plan to make ten I meant ten at a time. I'll start taking orders for the production drives once I have the prototype together and running properly.

The swingarm drive is disassembled for paint. We're really just waiting on some new hardware in order to be able to finish both drives. It should be here any day.

I'm really pleased by all of the purchase enquiries regarding the swing arm drive. Don't worry I won't sell out of them. When I said that I plan to make ten I meant ten at a time. I'll start taking orders for the production drives once I have the prototype together and running properly.

LightningRods

1 MW

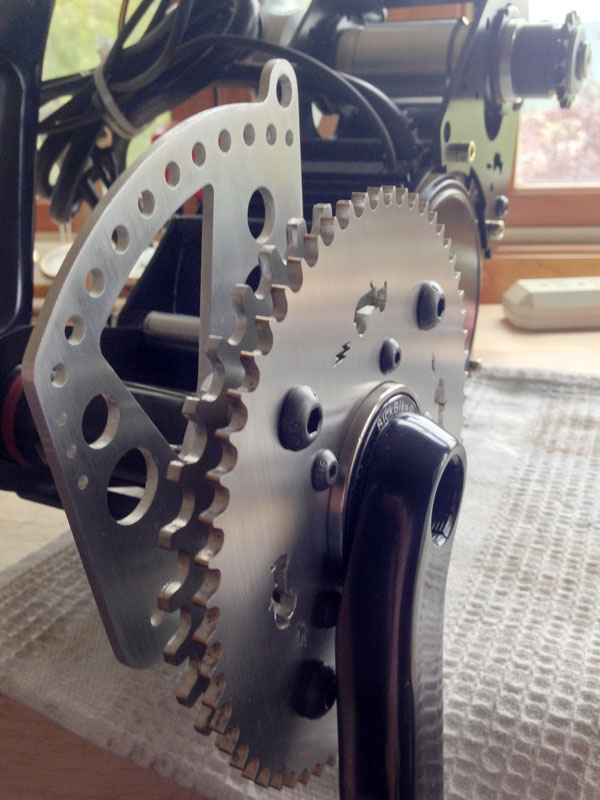

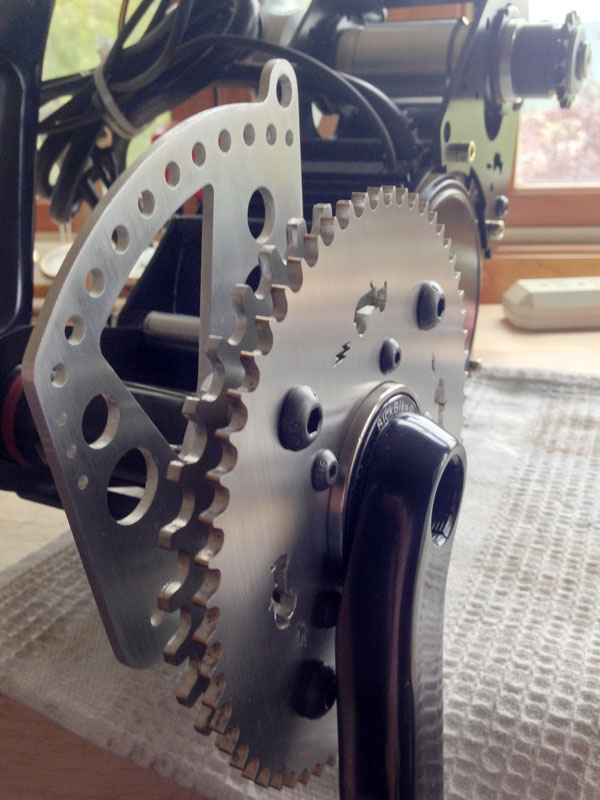

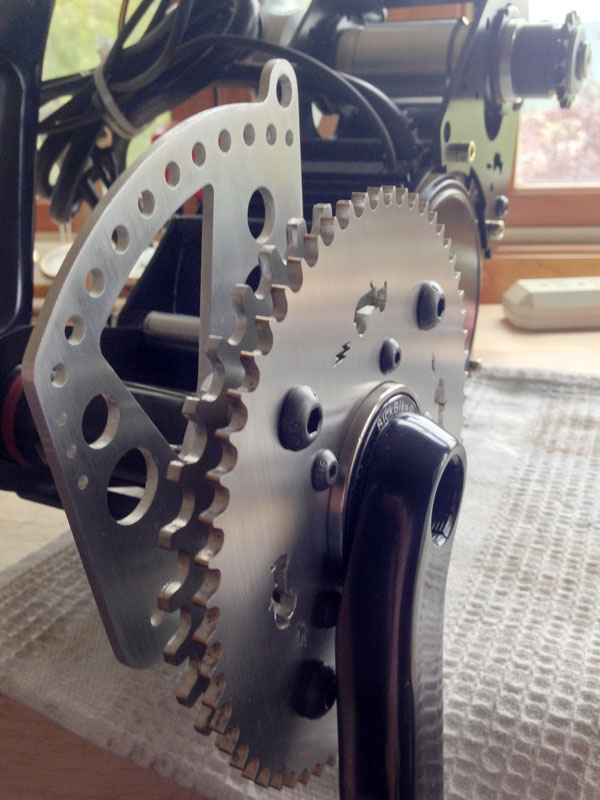

The chainwheel drive Qulbix mid drive is coming together. I assembled the new chainwheel parts today. 60 tooth 10 gauge stainless #219 driven sprocket, 34 tooth 11 gauge stainless 1/2" chainwheel, White Industries UHD freewheel, M8 class 10.9 hardened bolts for chainring bolts. In addition to all of this motorcycle grade hardware this drive also has 1/3 the reduction of my typical street/trail mid drive. You can't pedal with the motor- the chainwheel is spinning at over 300 rpm. However torque stress is reduced by 2/3 and you can now use the high tooth count sprockets on the rear hub and still have good speed.

The upper bracket bolts directly to the Qulbix battery box. It's not twisting or flexing no matter the power level. The lower bracket is now supported by 1/2" round aluminum standoffs and full width M6 10.9 bolts. There will be a spring loaded DH guide wheel/tensioner attached to the bottom rear of the aluminum guide plate and a urethane lined fence guide on the top.

The upper bracket bolts directly to the Qulbix battery box. It's not twisting or flexing no matter the power level. The lower bracket is now supported by 1/2" round aluminum standoffs and full width M6 10.9 bolts. There will be a spring loaded DH guide wheel/tensioner attached to the bottom rear of the aluminum guide plate and a urethane lined fence guide on the top.

Dogboy1200

100 W

If the crank speed is too fast to pedal anyway could you embrace that concept and eliminate the jack shaft and it's brackets. Then just turn the motor around in its bracket (so the shaft is on the same side as the chain rings) and put on one of your chain drive conversion sprockets with no freewheel on the motor. Then run the small sprocket on the motor to a large sprocket on the crank freewheel. Then have a sprocket as small as possible on the inside of the crank freewheel running to a big single speed sprocket on the wheel freewheel. I think the last stage should also be #219. This gives you a bike whose pedals technically work but have a very very low top speed and the drag of the motor cogging if you pedal with out it. On the upside the parts count of the system is the irreducible minimum. I have been thinking about trying this for a while now. Will the motor fit in the mounting bracket the other direction? I think this set up would also be narrower because you get rid of the primary side drive.LightningRods said:The chainwheel drive Qulbix mid drive is coming together. I assembled the new chainwheel parts today. 60 tooth 10 gauge stainless #219 driven sprocket, 34 tooth 11 gauge stainless 1/2" chainwheel, White Industries UHD freewheel, M8 class 10.9 hardened bolts for chainring bolts. In addition to all of this motorcycle grade hardware this drive also has 1/3 the reduction of my typical street/trail mid drive. You can't pedal with the motor- the chainwheel is spinning at over 300 rpm. However torque stress is reduced by 2/3 and you can now use the high tooth count sprockets on the rear hub and still have good speed.

The upper bracket bolts directly to the Qulbix battery box. It's not twisting or flexing no matter the power level. The lower bracket is now supported by 1/2" round aluminum standoffs and full width M6 10.9 bolts. There will be a spring loaded DH guide wheel/tensioner attached to the bottom rear of the aluminum guide plate and a urethane lined fence guide on the top.

LightningRods

1 MW

If you did what you propose reduction would be about 6:1 or 1/2 what it is now. Chainwheel rpm would be about 500. This could work fine for a single speed. Low speed sprockets would start to get too huge to shift with a derailleur.

The motor will rotate 180 in the motor bracket. I'm sure that what you want to do is possible. Single stage from the motor to the rear wheel is simpler.

The motor will rotate 180 in the motor bracket. I'm sure that what you want to do is possible. Single stage from the motor to the rear wheel is simpler.

Dogboy1200

100 W

Yes single speed is what I was envisioning. A 12 tooth on the motor and a 72 on the crank gives you a 6:1. Then maybe the smallest you could put on the inside of the crank is a 40 tooth (#219 sprocket) going to another 72 on the rear wheel 1.8:1. 6*1.8=10.8:1.LightningRods said:If you did what you propose reduction would be about 6:1 or 1/2 what it is now. Chainwheel rpm would be about 500. This could work fine for a single speed. Low speed sprockets would start to get too huge to shift with a derailleur.

The motor will rotate 180 in the motor bracket. I'm sure that what you want to do is possible. Single stage from the motor to the rear wheel is simpler.

LightningRods

1 MW

That would work. Sometimes we have to use the bottom bracket just because of the layout of the bike. It's the only way on most full suspension bikes.

Just for grins I made a #219 chainwheel with 103 BCD. I also have 40, 50 and 60 tooth 219 sprockets that can attach to a five bolt freewheel. So most of the parts to do what you have in mind already exist.

This particular mid drive that I'm working on is meant to run through multiple gears. For a single speed solution on the Qulbix I have the swingarm mount left hand drive. I have other applications in mind for that single speed drive...

Just for grins I made a #219 chainwheel with 103 BCD. I also have 40, 50 and 60 tooth 219 sprockets that can attach to a five bolt freewheel. So most of the parts to do what you have in mind already exist.

This particular mid drive that I'm working on is meant to run through multiple gears. For a single speed solution on the Qulbix I have the swingarm mount left hand drive. I have other applications in mind for that single speed drive...

Dogboy1200

100 W

Great! I think I might give that a go after I finish my current Fat Bike project.

Similar threads

- Replies

- 18

- Views

- 736

- Replies

- 15

- Views

- 5,030

- Replies

- 19

- Views

- 1,725

- Replies

- 6

- Views

- 913

- Replies

- 25

- Views

- 3,052