Thanks for all of the feedback. I currently build three drives that will fit the Qulbix frames.

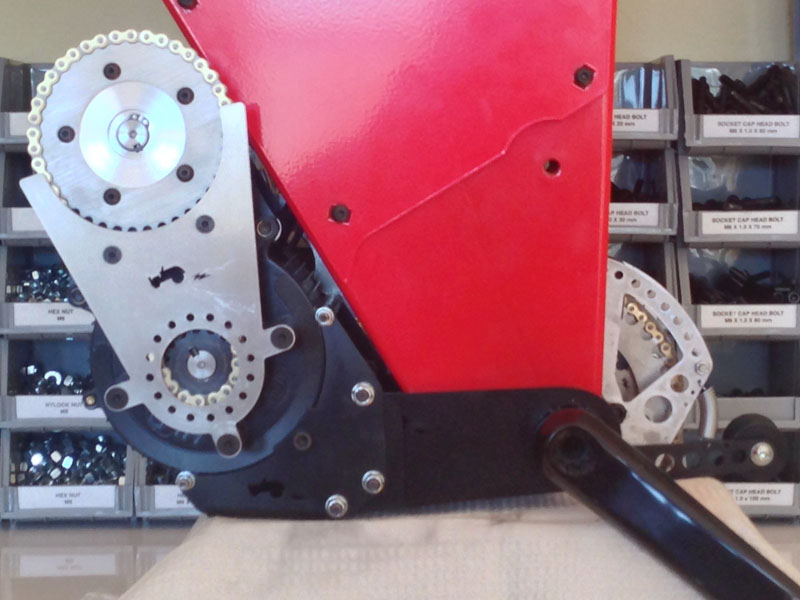

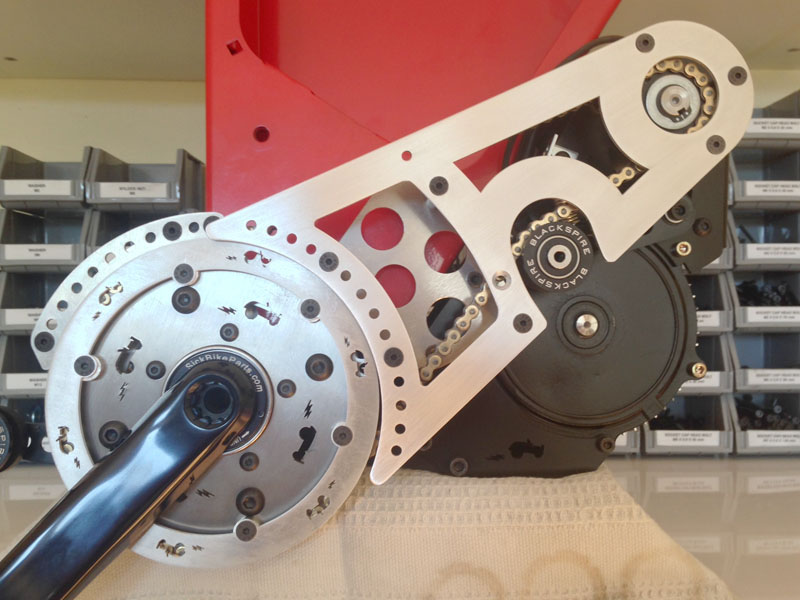

#1- Two stage bottom bracket drive.

Mounts to: Bottom bracket and front of battery box.

Motor reduction in drive unit: From 40:1 to 8:1

Freewheels: Two. One in primary driven sprocket for pedaling, one in BB for motoring without pedaling. (The sample drive in the photo has an optional billet freewheel delete hub in the sprocket)

Regen: No

Can pedal with motor: Yes, at reductions of 30:1 or greater.

Motor runs through bike gears: Yes

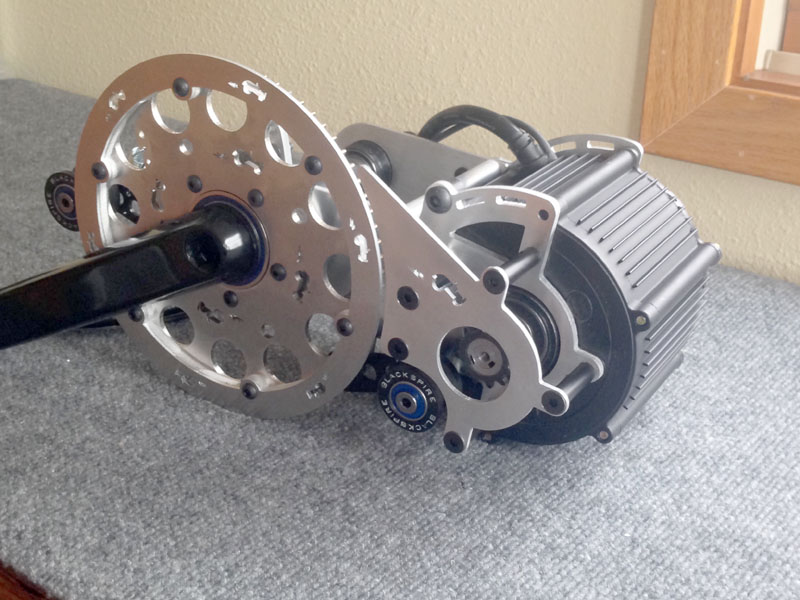

#2- One stage bottom bracket drive.

Mounts to: Bottom bracket and front of battery box.

Motor reduction in drive unit: 6:1. Final drive ratio ranges from 11.5:1 to 3:1.

Freewheels: One. One in BB for motoring without pedaling.

Regen: No

Can pedal with motor: No.

Motor runs through bike gears: Yes, or two stage single speed with a single rear sprocket on right.

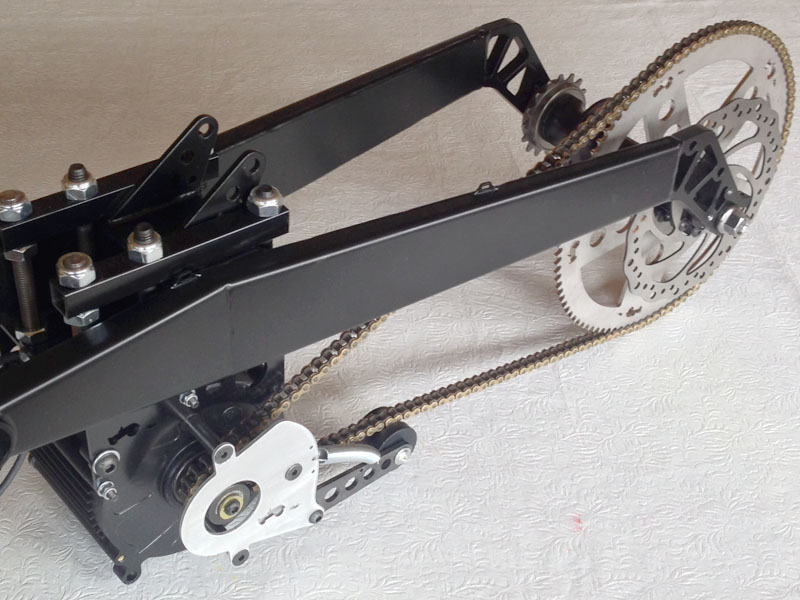

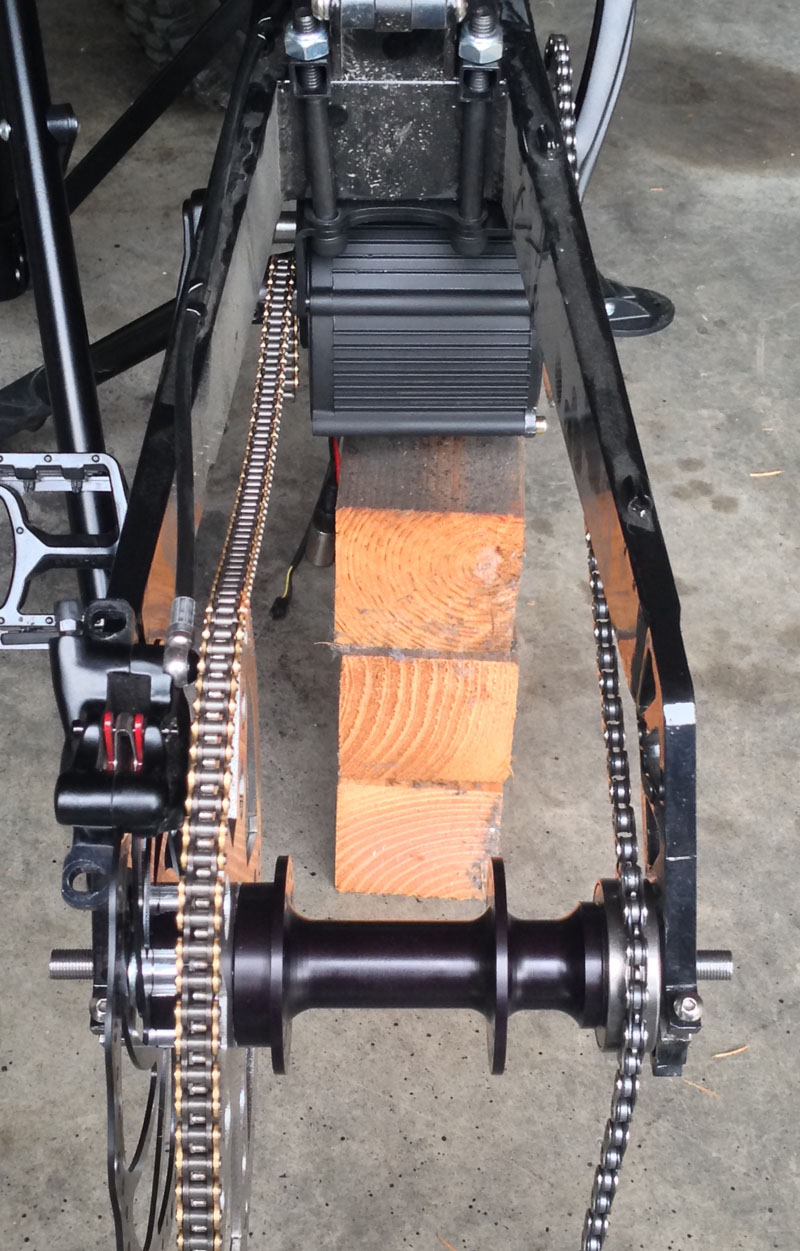

#3- Swingarm drive.

Mounts to: Swingarm

Motor reduction in drive unit: None. 8:1 reduction to rear wheel is standard.

Freewheels: None

Regen: Yes

Can pedal with motor: Yes, up to the limit of the pedal gearing.

Motor runs through bike gears: No. Single speed on left side.

There are advantages and disadvantages to each one. The two stage drive is best for steep climbing, pedaling with the motor, extending battery range. The one stage is best for going fast, moderate climbing, running over 3000 watts through the bike gears. The swingarm drive is meant to be as simple as possible. Many people avoid mid drives just because of the number of moving parts. The swing arm drive is an alternative to hub motors that is lighter, has reduction gearing, and is positioned close to the fulcrum point of the swing arm.