I just updated the first page, making the focus on the main advantages and unique selling propositions, but I kept the project status and in the end the history and motivation. Here it is:

-----

This OpenSource firmware/embedded software runs on the BMSBattery S/Kunteng KT motor controllers.

The main advantages of this controllers are:

1. sine wave/"FOC": motors run silent and very efficient

2. cheap: starting at 20€

3. widely available: many online shops sell them and ship to worldwide

4. various sizes e powers: from 0.25kW up to 5kW (72V, 70A, 24 mosfets)

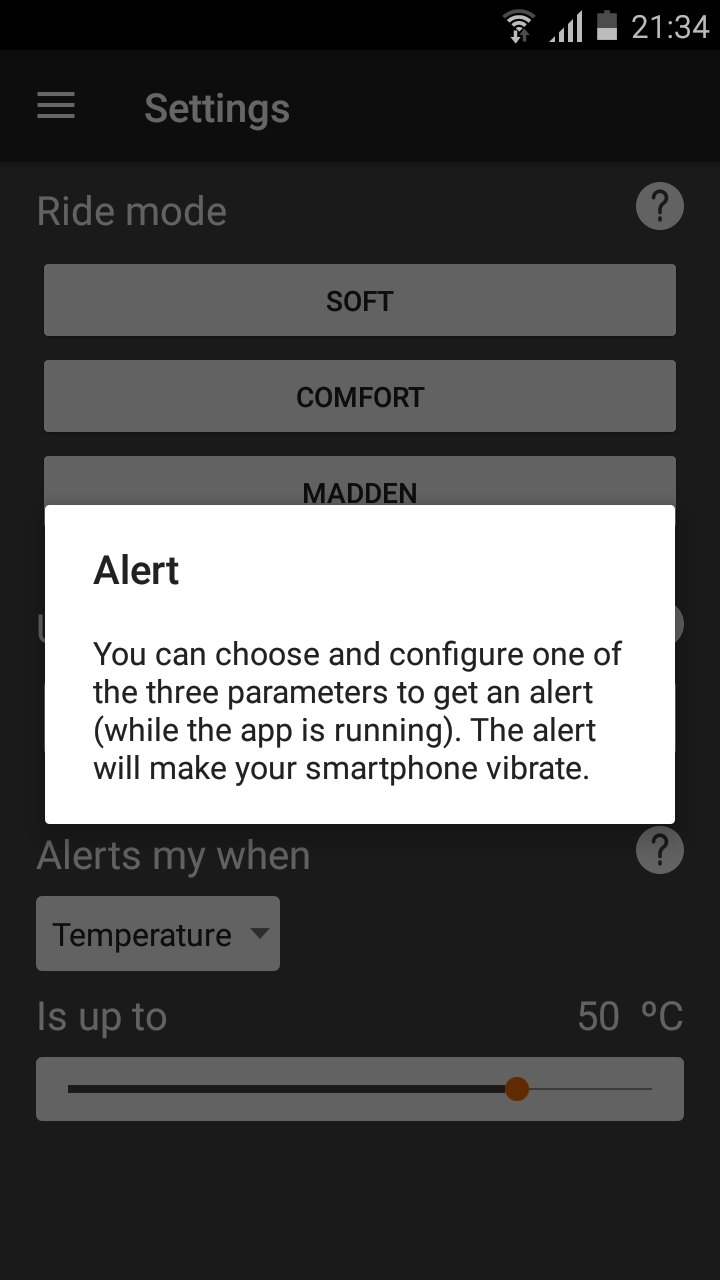

5. supports LCD and Bluetooth mobile app

6. schematic available: important if you want to mod/hack, repair or even build your own controller

The main advantages of our OpenSource firmware/embedded software are:

1. sine wave/"FOC" max efficiency: motors run silent and very efficient and is possible to tune a parameter to get the best efficiency possible for a specific motor

2. flexible and OpenSource: more than customization, any feature for some specific need can be easily implemented and for free (no need to pay any commercial license)

3. throttle, PAS and torque sensor: all of them are supported

4. LCD3 and LCD5: all of them are supported

5. regen/ebrake: works very well on the direct drive motors

6. motor torque controller/motor current controller

7. motor speed controller

The

firmware sources are available on github and the developers and users

communicate together on the Endless forum message.

Project status

As of 14 December 2017, the firmware is still experimental however we already use it on our EBikes

See some videos on youtube by searching on youtube for “OpenSource firmware Ebike BMSBattery”.

Current state:

1. Tested on:

1) S06S and S12S motor controllers

2) Q85, Q100 and Q11 (direct drive) motors

3) 24V and 48V batteries

4) LCD3 and LCD5

5) throttle; PAS and pedal torque sensor

2. Features:

1) motor works well: starts with block commutation and then changes to sinewave

1- implemented “very low resolution FOC” that gives good efficiency (see next point)

2- efficiency is good, at least equal to original firmware and near to Lishui 12 fets FOC controller

1> there is one parameter that can be tweaked to make sure firmware is getting out the most efficiency possible from the controller

4- regen ebrake (see this video showing regen ebake working and Regen ebrake like coast brakes)

5- torque controller/motor current controller

6- motor speed controller

2) LCD3 and LCD5 works (not all features are implemented yet). What works:

8- shows:

1> motor speed

2> battery state

3> motor power usage

4> throttle active

5> brake active

6> some errors

9- changes:

7> assist level

8> max motor speed

9> P3: Power Assist Control Mode

10> C5: Controller Maximum Current Adjustment Mode

3) Throttle: works

4) Brakes: works

5) PAS: works

6) Torque sensor: works

Project history and motivation

I started this project on 25 April 2017 because I would like develop an OpenSource firmware for the EBike controllers. Why I am wanted to do that? because I wanted to use a well know controller that it is easy to repair/mod/adapt for my specific projects. I am developing the firmware for it, as OpenSource and I would like to share with others that have the same needs. My mission is similar to the Tesla mission (https://www.tesla.com/blog/mission-tesla): "to accelerate the advent of sustainable transport" and innovation on personal light electric vehicles.

The idea was to found a cheap and widely available EBike controller that could be programmable. I was developing, since 2015, firmware for the controllers of electric unicyles and they use the microcontroller STM32F103, that is very cheap and popular - the board is also cheap and widely available on market, that comes from China. By the way, the hoverboards controllers use the same STM32F103 microcontroller.

For EBikes, I found the most recent BMSBattery S series controllers like S06S sinewave use the STM8S105C6T6 microcontroller that is programmable, easy and cheap to develop for. There are OpenSource and cheap development tools for it.

BMSBattery sells the S series controllers, starting with S06S of 24/36V 15A (0.5kW, 6 mosfets) up to S12S of 72V 40A (2.9kW, 12 mosfets).

This controllers are developed by Kuteng (http://www.szktdz.com/en/ | http://minshine.cn/). There are available on the market in many different versions of Kuteng controllers, from 24V, 36V, 48V and 72V, with max currents of 70A (5kW, 18 mosfets).

Over the time, more and more users/developers did join the project and it was not anymore my project but a community project as I wished since the begin! You can find their nicknames and contributions on the forum message or git commits.