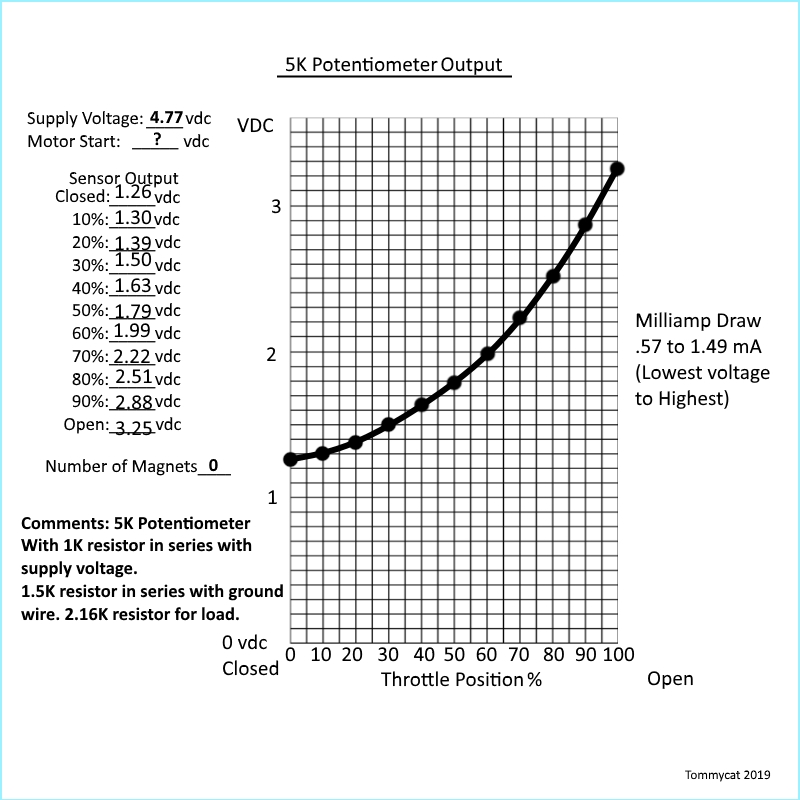

It could certainly change resistance, but since the controller isn't measuring the complete resistance of the throttle and determining what to do based on that, it won't affect the behavior.speedyebikenoob said:Oh I see. I was assuming it might have been there because the resistance values in the throttle could change depending on the temperature, and you obviously don't want your bike to run off (although probably very slowly) as soon as you turn the power on.

The part of the resistance above the wiper will change at the same rate as taht below the wiper, so the ratio of values between the two remains the same--and that's what the controller is checking (whether it reads resistance, current, or voltage).

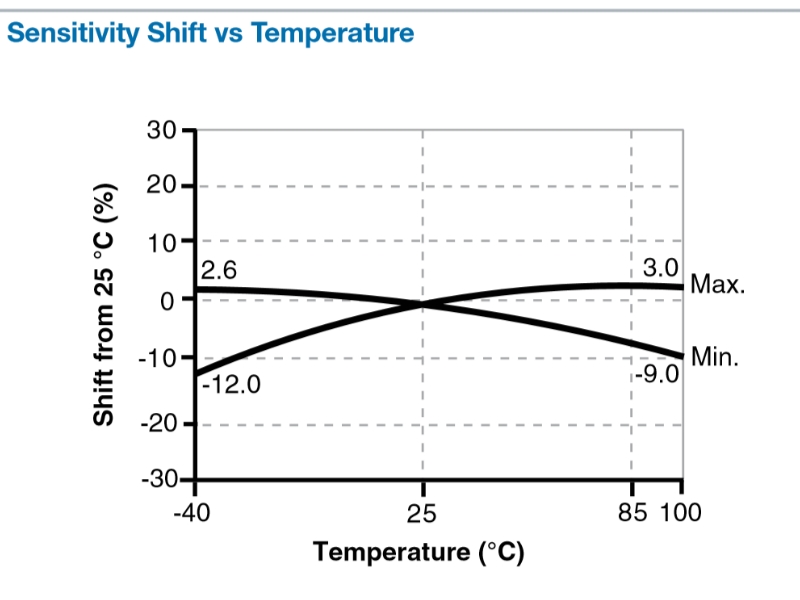

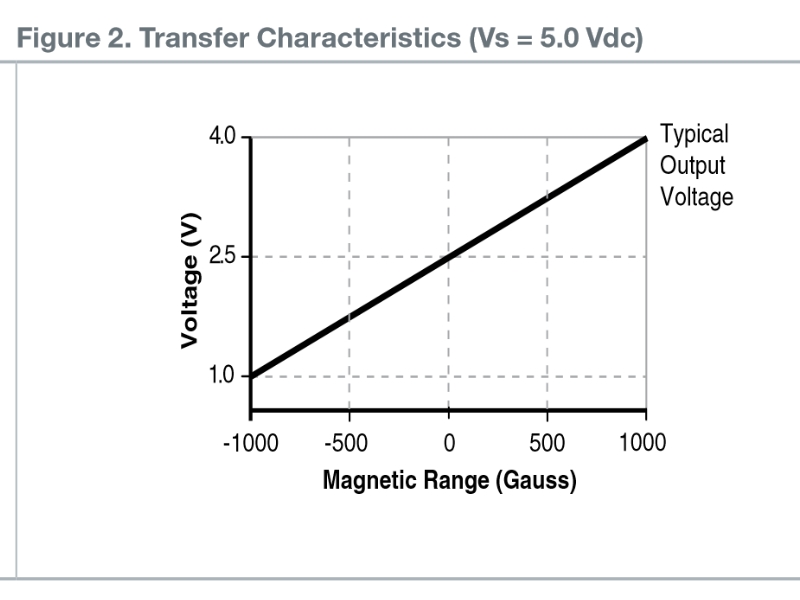

Hall throttles are different, and are not based on resistance...but they also change characteristics with temperature...but also not in a way that would affect the signal coming out.

If they really wanted to make a runaway-failure-proof throttle, it's pretty much this easy:

--two throttles in the same body, mechanically linked to turn at the same time and rate.

--first one is wired normally.

--second one is wired backwards.

--controller (has to be designed for this kind of throttle) checks that each one is changing at the same rate as the other. If it isn't, it stops powering the motor at all, and shuts down with a throttle error. The "hard" part is making the controller do this, because none of the common ebike controllers are designed to. (just some of the expensive OEM types on scooters/motorcycles/cars/etc, AFAICR).

--*however*....you can actually build a fairly simple circuit (analog or computational) that could be installed inside the controller casing of a cheap controller (that couldn't normally support such a throttle) that translates the dual/inverse throttle signal input pair into a single output signal that the controller understands. It coudl even add a simple layer of protection for the controller against shorts in the wiring, water ingress in the throttle, etc., that can cause the controller to fail. (see ZombieSS's Throttle Tamer for an example of a tiny computational throttle translation unit; it does different stuff, but the idea is similar).

That prevents a number of potential runaway issues, including one of the most common: broken ground between throttle and controller, whcih results in basically full throttle voltage on the signal line. Some controllers fault and shutdown when this happens *because* the voltage goes above the high-throttle-limit, but some controllers don't.