matt912836 said:flat tire said:matt912836 said:Ideas?

The motor is made for bottom dollar by people who don't care that much and you slightly damaged some insulation / started to connect a winding to the stator or another winding when the internals were shocked / moved around slightly upon crashing. Happens all the time in these cheap chinese motors when ridden hard or crashed.

The damage is probably terminal and the only solution is to rewind the motor. Preferably with a decent magnet wire and properly isolated stator next time. Then you need to epoxy the windings so they can't move around.Tommm said:Take it apart then. See if the shaft moves as easily as it did before. Same with the freewheel.

I was really hoping it was just a bearing gone bad or something, but upon further inspection, the top bolt on the drive side the motor holding the motor onto the mount happens to have sheered off right at the beginning of the threads. I will have to use a left handed drill bit to get the threaded piece out the motor, hopefully this was the original problem but honestly not sure as I'm only noticing this now after continuing to ride the motor hard (wheelies and all) and almost having the motor chain snap on me. Now i see why the chain almost snapped, because the motor is now moving in the mount. Only thing is it definitely wasnt doing this immediately after the crash, it's only now the motor is clear its loose.

Anyone know the size of the bolts that are on the freewheel side of the motor? Its atleast an inch and a half before the threads actually begin.

Also, if this doesnt fix the problem, wheres the easiest and cheapest place to source a replacement motor? I see some replies about it being $99 for a new one shipped..

You see $99 because the cyclone warranty works that way, you pay for shipping only.

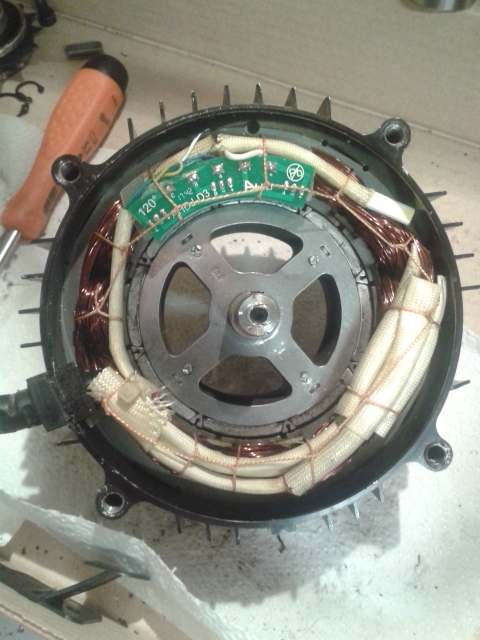

The motor has 2 parts, gearbox and motor core. You don't need to get the whole thing if you stripped something. You got any pictures?