Trevonsphere

10 µW

- Joined

- Jul 30, 2019

- Messages

- 6

Greetings from southwest England. Been lurking here months. Some at Grin will recognise me. Anyway, time to pop-up, in my guise of a small-scale e-bike converter-builder (amongst many other things). Decided e-bikes was the way to go in the current climate (-change), as every other person I know wants one but would rather not pay silly prices or risk dubious imports.

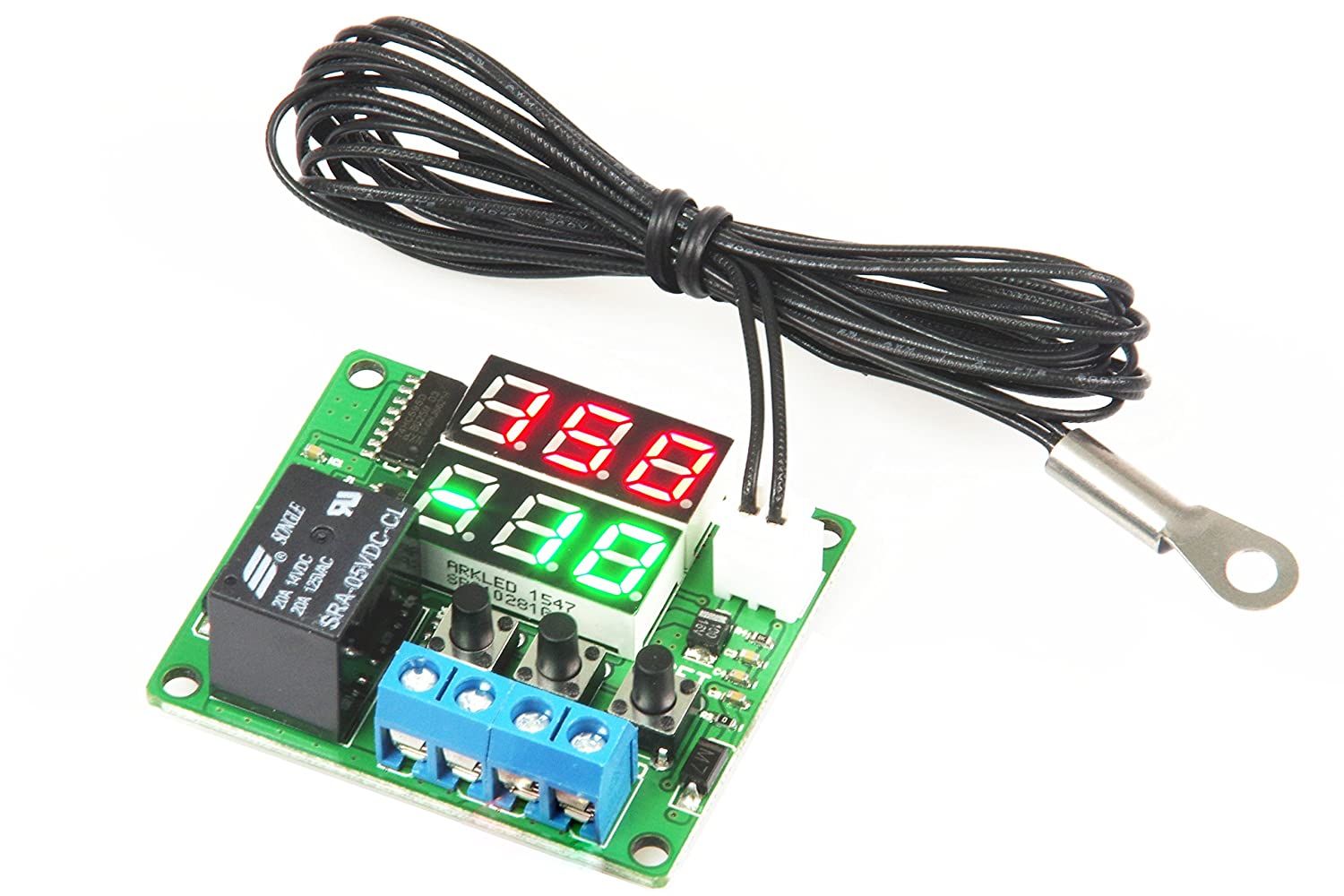

I'm on this particular thread because I've just imported a bunch of Bafang G310s, with considerable effort, and am still trying to deal with the fallout. Language misinterpretation issues meant I ended-up with motors with 0.75 m long cables to the Higo-type plug, which I've decided I shorten on a couple (at the motor end), along with fitting an internal thermistor. I've got as far as Grin's disassembly video goes, but would really like to get the stator out of the case too, to get at the wiring behind, before considering whether a non-moulded-on plug might be a better idea.

So, anyone anything to report on getting the stator out of one of these?

I'm on this particular thread because I've just imported a bunch of Bafang G310s, with considerable effort, and am still trying to deal with the fallout. Language misinterpretation issues meant I ended-up with motors with 0.75 m long cables to the Higo-type plug, which I've decided I shorten on a couple (at the motor end), along with fitting an internal thermistor. I've got as far as Grin's disassembly video goes, but would really like to get the stator out of the case too, to get at the wiring behind, before considering whether a non-moulded-on plug might be a better idea.

So, anyone anything to report on getting the stator out of one of these?