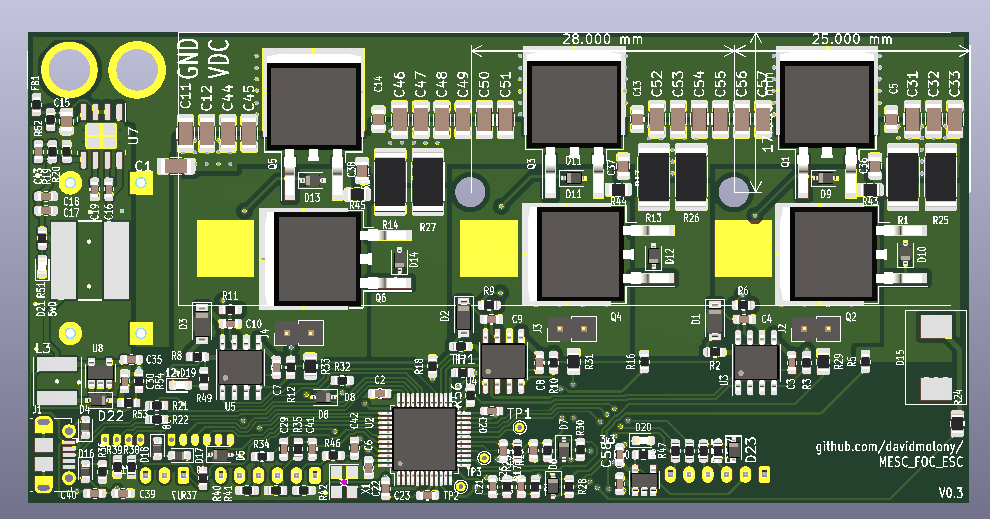

That's an interesting video and set of data. By gross extrapolation, I conclude:

Your setup - 98A, 5mohm 150V FET, DC - 50W heat generated, limiting factor the leg, massive heatsinking

My setup - 80A, 3mohm 100V FET - 19.2W resistive loss, switching... some amount...say I assume a slow 100ns switch times, 80A80V 35kHz... = ~22W (upper limit)

Total ~40 W, less heatsinking, but share between 2 FETs (to an extent, 50% at half duty cycle).

It's definitely in a similar kind of region, less likely to have the leg as the hottest point like your setup did, since the leg and die bond is purely resistive so ~64% the power, but the lesser heatsinking isn't going to help. Overall, I think that your assessment of 80A continuous being optimistic sounds about right, but if you re-run at 70A70V => 14.7W resistive, 17W switching, 32W total (90W for the whole board, plus the other resistive losses) it starts to look more promising with decent airflow...

This is the first time I have run this calculation written down (done it in my head with the same result a few times), and it really does highlight the importance of the switching losses, they look like they account for as much as the resistive! It means more/bigger FETS != less heatsinking!

Considering 3 FETs - ST micro STH310N and the CR Micro CRSS042N10N (50p FET from some Chinese brand I took a flyer on when I got the last boards SMT'd) and Infineon IPT020N10N3ATMA1 - the most badass 100V H-SOF mosfet I can find:

STH310N Rdson 1.9mohm, rise time 108ns, fall time 40ns

CRSS042N10N Rdson 3.4mohm, rise time 32ns, fall time 27ns (do we believe these specs from a no name brand? Hell, do we believe ST micro or Infineon?)

IPT020N10N3ATMA1 1.7mohm, rise time 58ns, fall time 18ns

80A80V 35khz I get

STH310N 28.7W

CRSS042N10N 28.36W - less!!!

IPT020N10N3ATMA1 19.6W , assuming an unrealistic 1.7ohm gate drive (~7 amp gate drive required)

Well aha! I could use the TI CSD19536 which has rise and fall times of 8 and 6 ns respectively, a package limited continuous current of 200A (TO-263-3 :lol: ) and a 2.2mohm Rdson giving 15.64W, but very funny TI, how did you achieve your zero ohm gate drive? Measure the switch times at 10ohm and 5ohm and extrapolate to zero? How did you stop the tiny little leg fusing? Run it underwater? Why are you like this...

Quit bullshitting us TI, I have more reason to believe in CR micro than you.