vulcanears

10 mW

- Joined

- Mar 1, 2019

- Messages

- 24

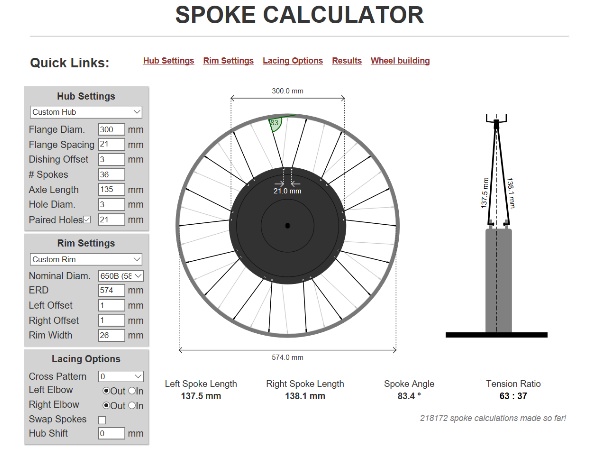

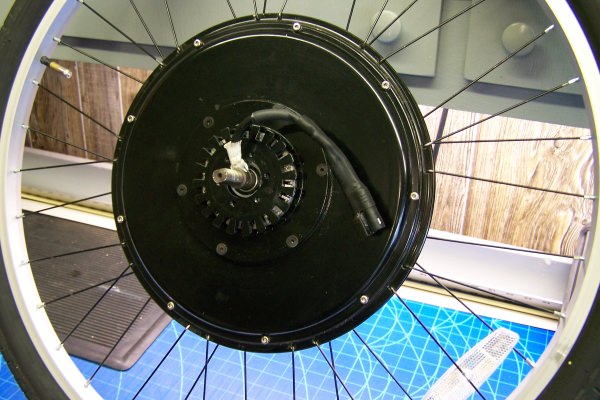

I just built a 27.5" wheel with a voilamart motor and the angle between the spoke nipples and the spokes looks extremely dodgy and I'm concerned that it spokes will fail at that bend point. Is there any way to improve this with this build or my next one?

Would nipple washers improve it?

Thank you very much in advance!

Would nipple washers improve it?

Thank you very much in advance!