DrkAngel

1 GW

Oops!

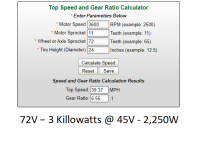

2000w motor output will not get you to 40mph!

If geared perfectly, you could attain around 37mph. *

36V "1000w" motor is labeled 36V x 30.5A = 1098 input watts x 80% efficiency = 878.4 motor output watts

48V "1000w" motor is labeled 48V x 20.8A = 998.4 input watts x 80% efficiency = 798.72 motor output watts

< 1800w motor output, if geared perfectly, could attain near 36mph. *

Don't fall victim to deceivious sellers who rate motors by input watts!

Compare to your original eZip "450w" motor - 24V x 35A oem controller = 840w input

If you switched to a 36V 35A controller, your motor was taking in 1260w for a 675w motor output.

40mph requires a minimum 2250w motor output, 2500w to guarantee?

* based on typical mountain bike

2000w motor output will not get you to 40mph!

If geared perfectly, you could attain around 37mph. *

36V "1000w" motor is labeled 36V x 30.5A = 1098 input watts x 80% efficiency = 878.4 motor output watts

48V "1000w" motor is labeled 48V x 20.8A = 998.4 input watts x 80% efficiency = 798.72 motor output watts

< 1800w motor output, if geared perfectly, could attain near 36mph. *

Don't fall victim to deceivious sellers who rate motors by input watts!

Compare to your original eZip "450w" motor - 24V x 35A oem controller = 840w input

If you switched to a 36V 35A controller, your motor was taking in 1260w for a 675w motor output.

40mph requires a minimum 2250w motor output, 2500w to guarantee?

* based on typical mountain bike