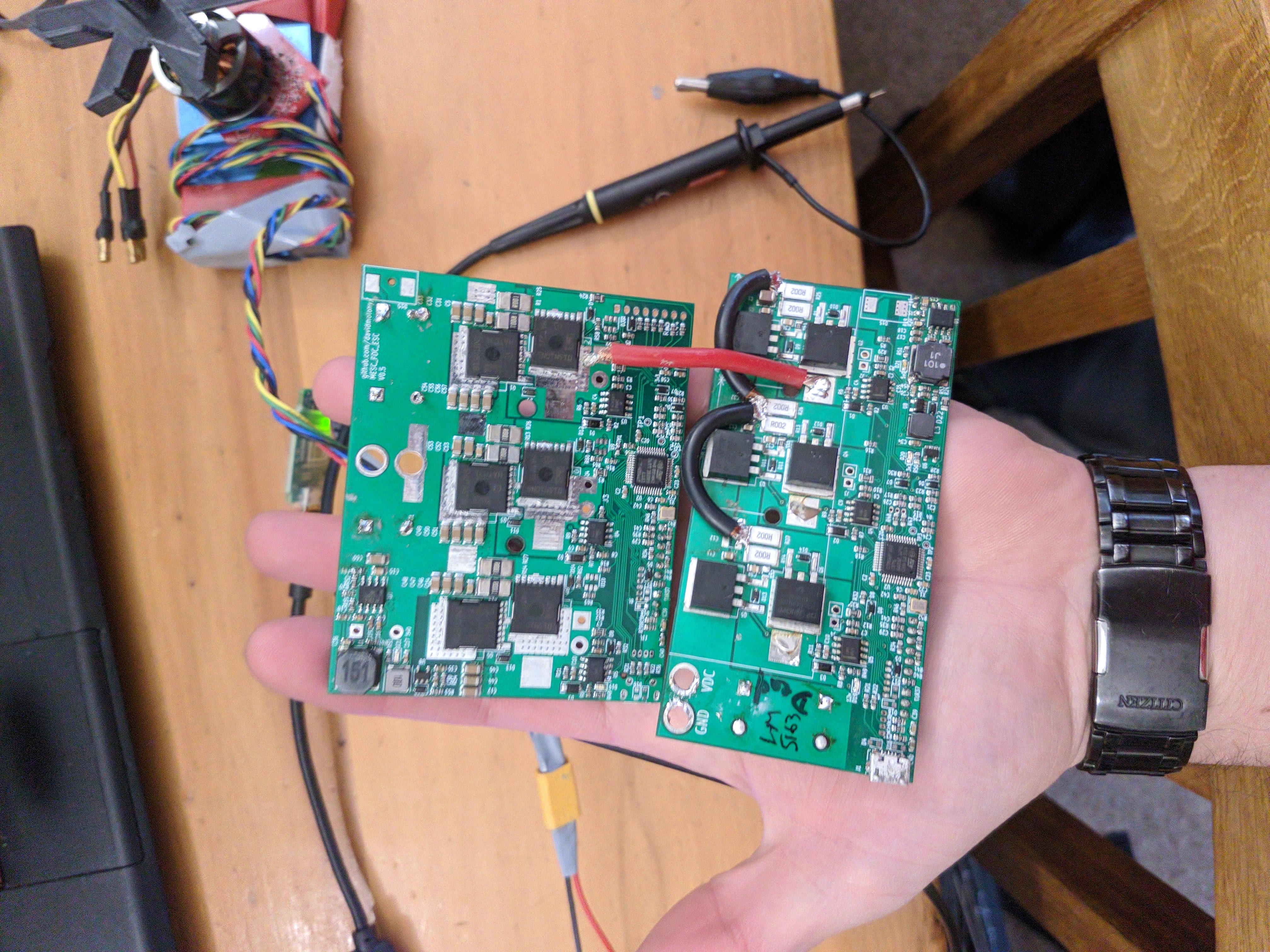

New boards finally arrived last Friday, after FedEx took care of them for me, for 3 weeks. Thanks FedEx!

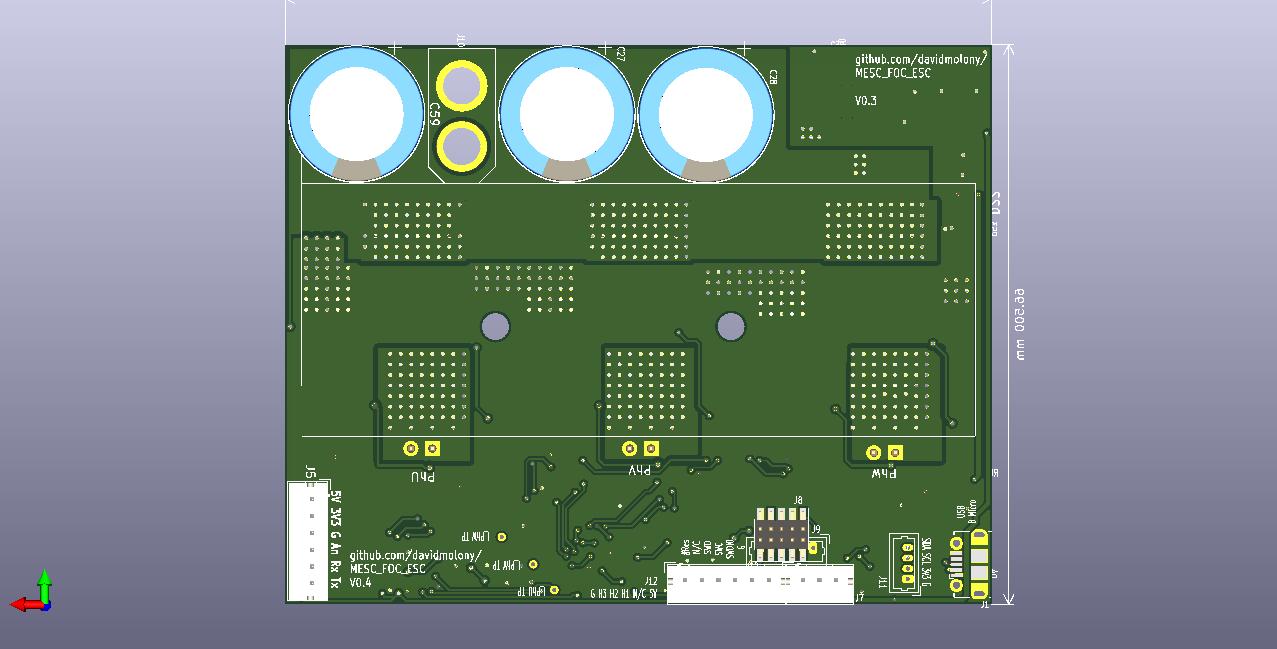

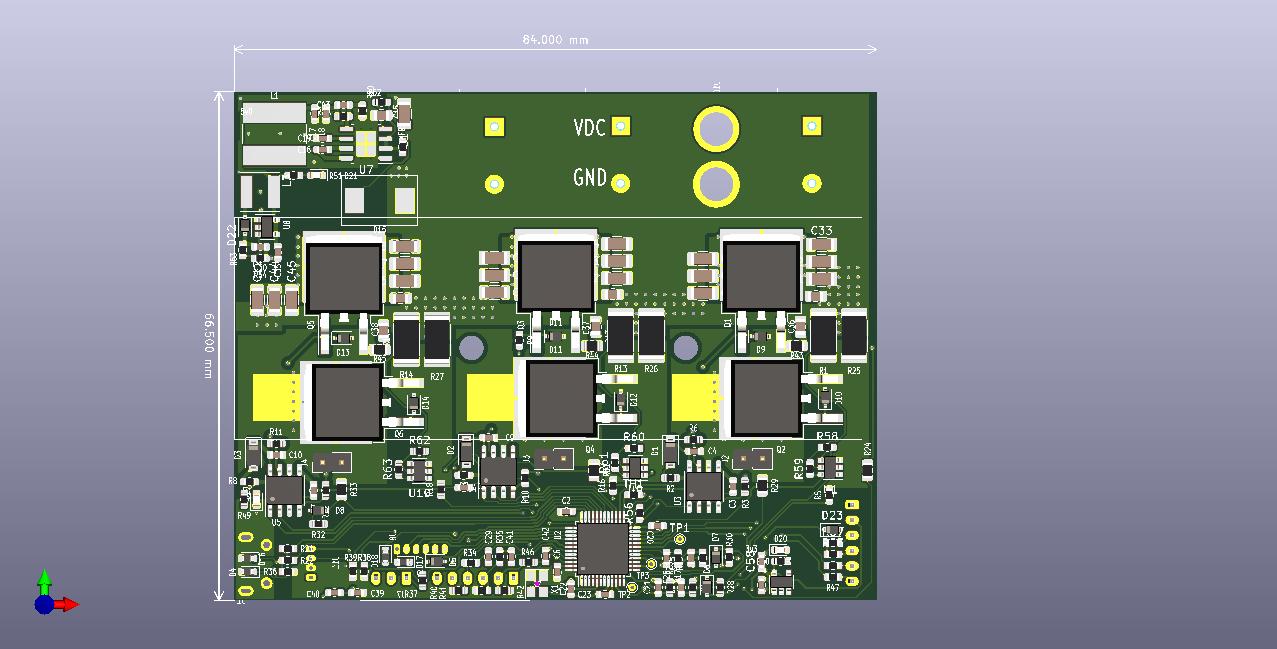

They are slightly larger - about 10% more area, but narrowed and deeper than the old ones. Still not exactly huge.

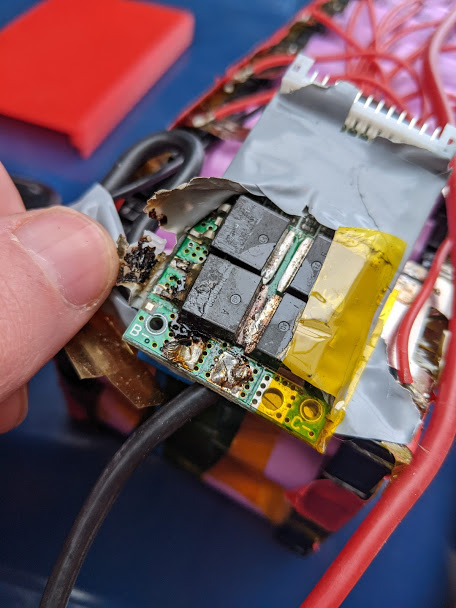

There have been some highs and lows! but the new boards seem really nice. I really really do not have enough time to be doing this unfortunately. I'd love to be spending hours a week, but alas.

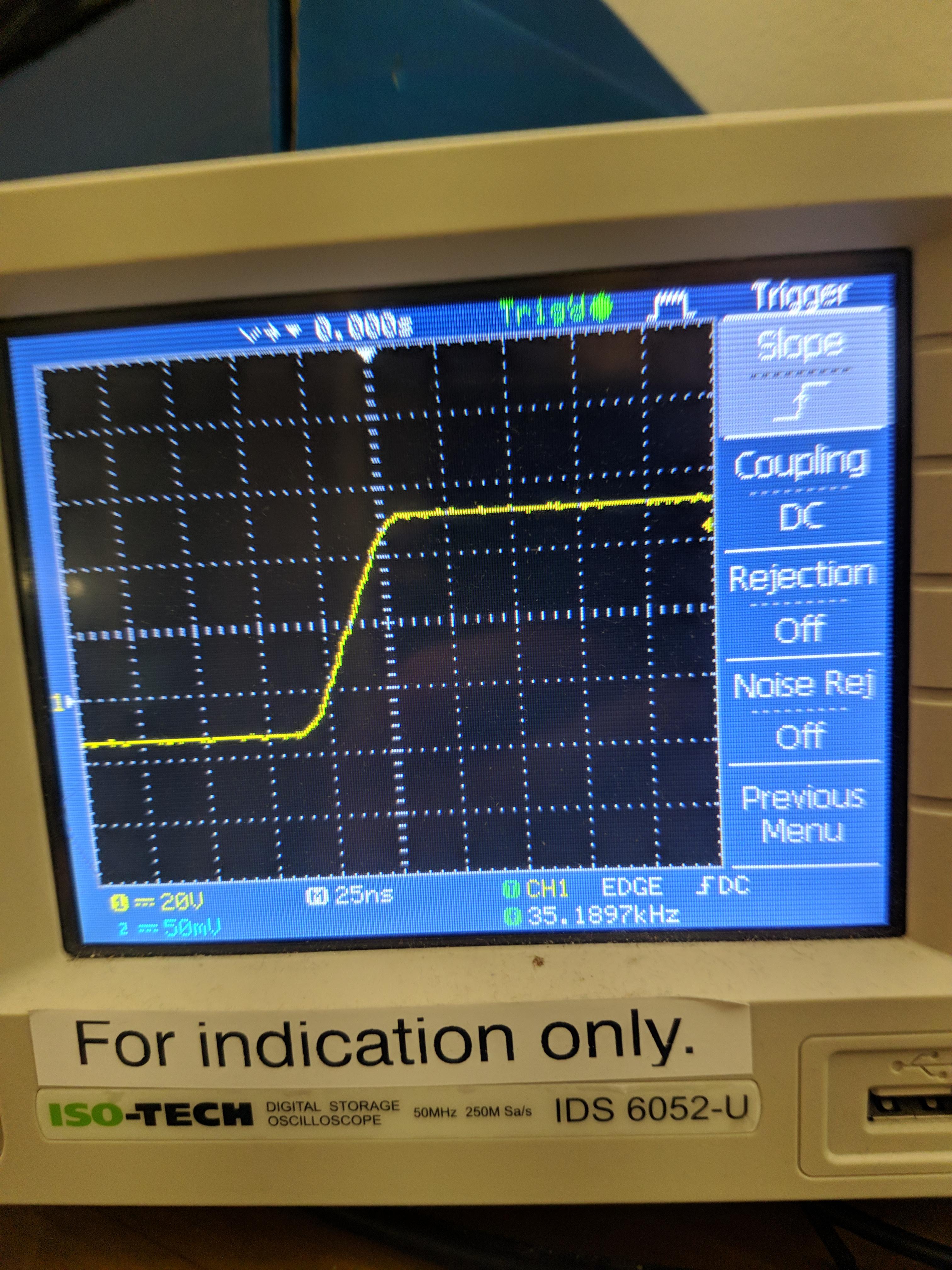

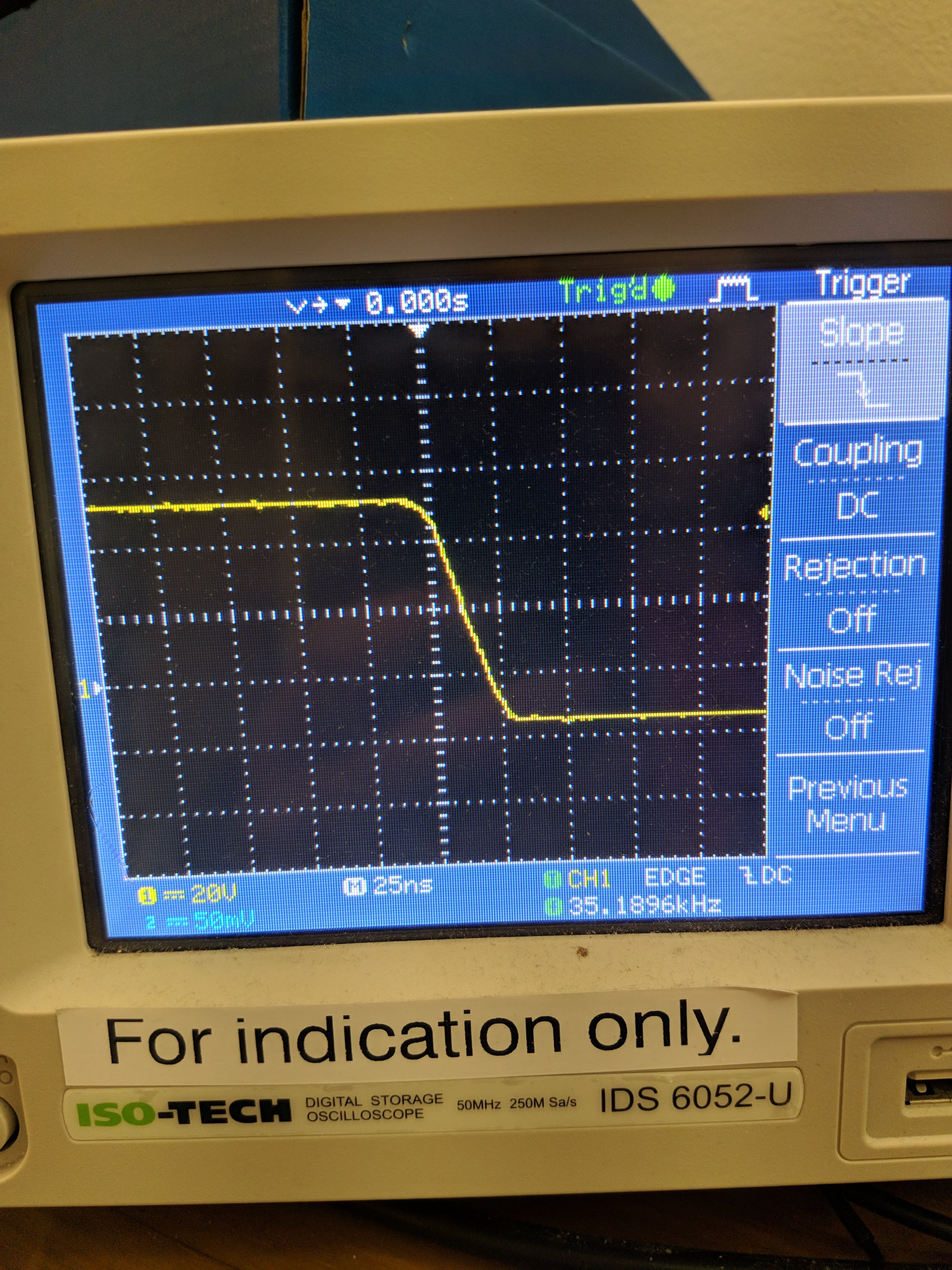

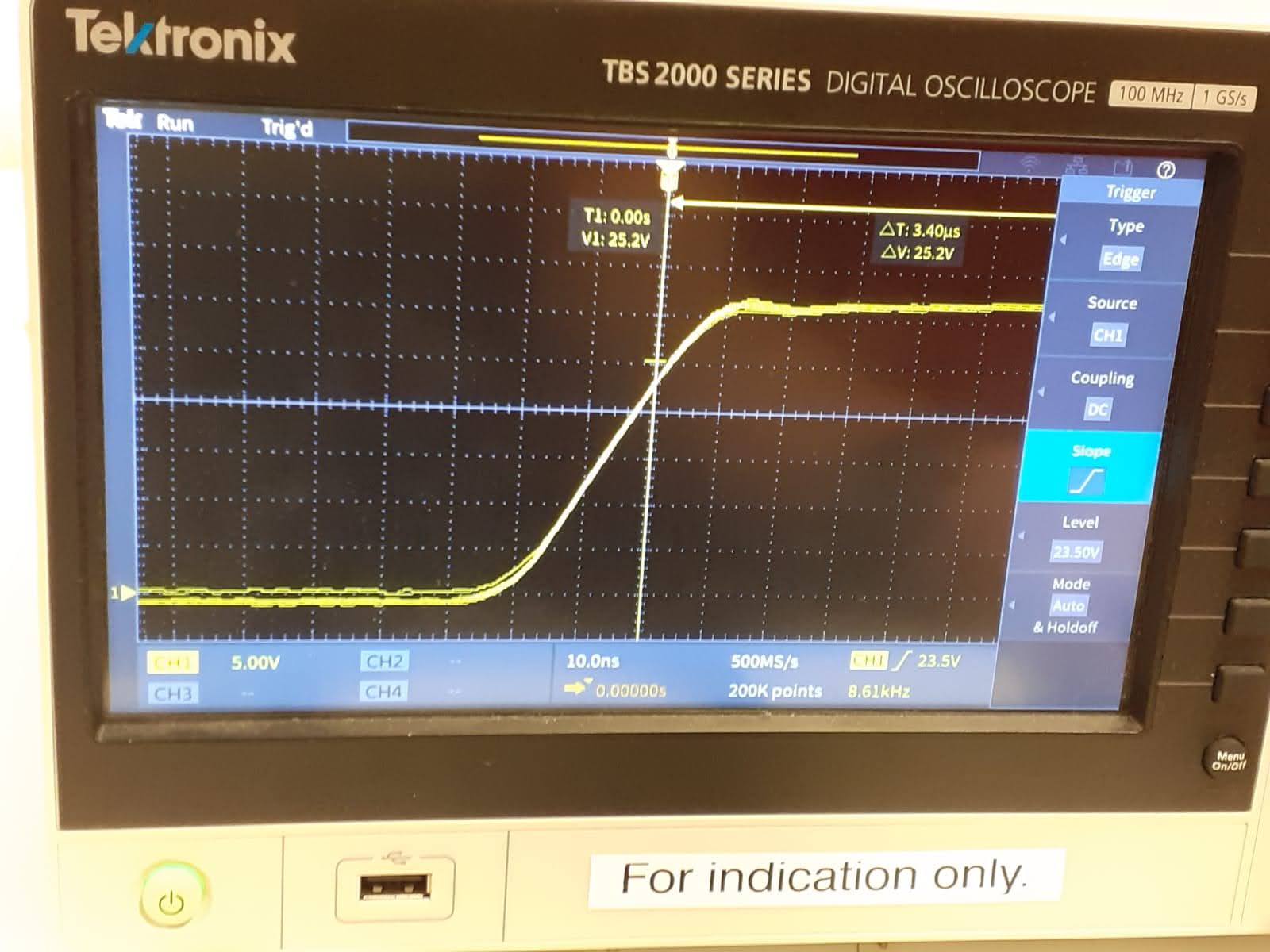

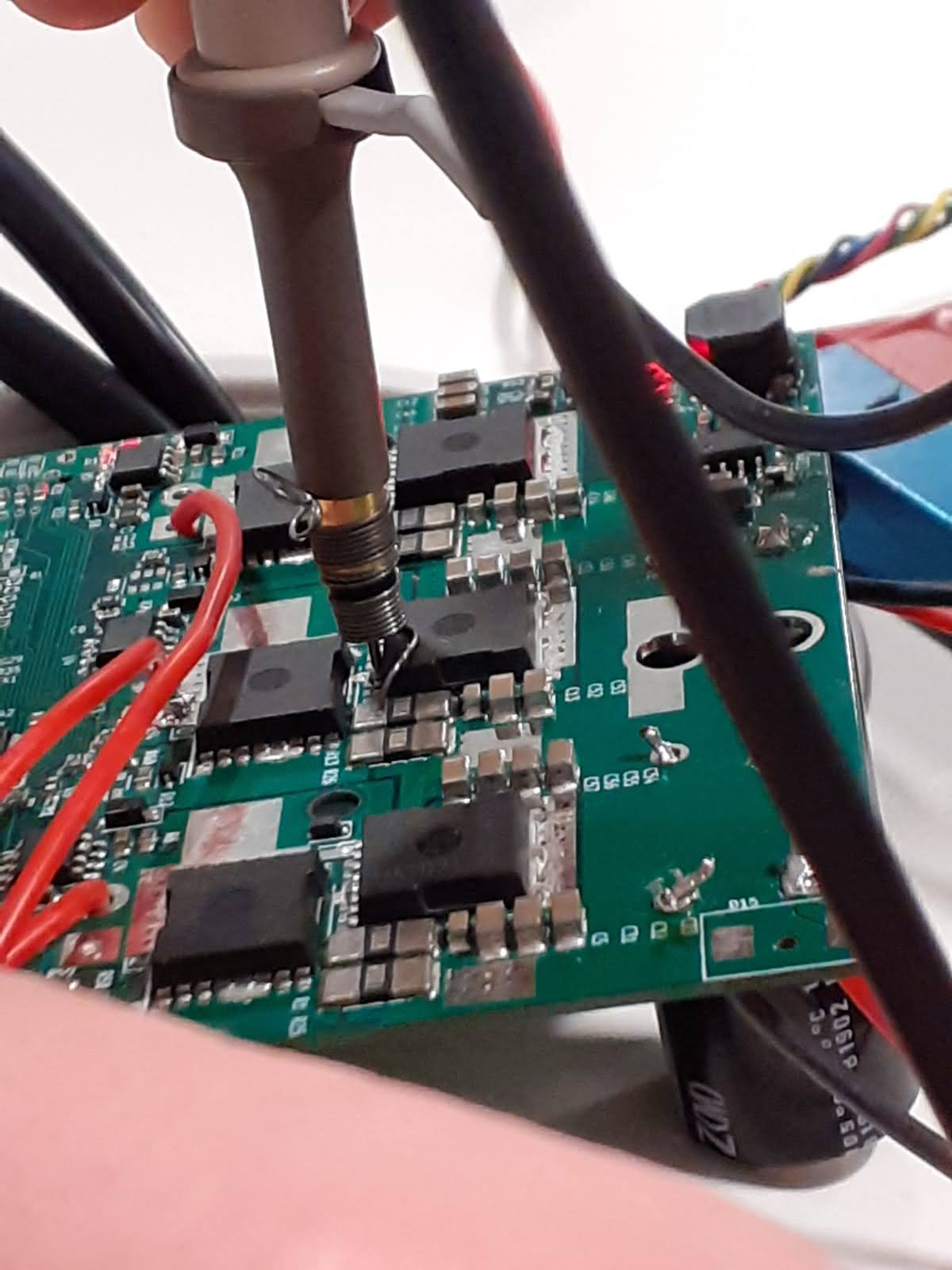

The ringing, or lack of it is beautiful. I find this incredible, bordering on impossible - roughly 30ns switching time and zero ringing. Mind blown; I designed the layout to be very very low inductance, but this exceeds all expectations... I thought the old one was good. The new FETs and layoutith the extra ground plane (4 layer is now same price as 2 layer so I thought meh, why not) seems to have worked a treat... Let's hope it works well when it finally stops raining and I can take it out to play. I have been warned many times by Zombies and an old colleague that switching this fast might be a bad idea, but efficiency! I am hoping that with this little ringing, nothing bad is going to happen.

It was so good, I thought... This can't possibly be real, so I took it to work to use the expensive 'scope... and it seems it really is basically ringing free. So this should be good up to 20s 84V with the 100V FETs and 600V gate drives!

Additionally, the current waveforms are a lot nicer since the DCDC converters have been moved away from the shunt lines, even before I have tried the standalone Opamps - they might not be needed after all. Much much quieter. I am generally very pleased so far with this new revision.

The bad news is that I am nearly unable to solder the wires to the board, the heat sinking into the various copper pours is a complete nightmare to solder to.

And of course... when drinking too much, and when it is pouring with rain so you can't really go outside, there's always repurposing the old PCB to be done. :lol: Just wired my headphone output into the analog of the STM32 and it modulates the PWM with the music, so the motor plays music... and if I attach a speaker to it, it plays music loud.

[youtube]https://www.youtube.com/watch?v=OGw6MtW5sXE&feature=youtu.be[/youtube]

Edit: Moved the pictures from google photos to Github, because Google is still inexplicable... It works on half my devices with random browsers.