You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

QS 3000w midmotor

- Thread starter bionicon

- Start date

larsb

1 MW

john61ct said:Why do people use the 3kW / 4kW designators?

138 205 273, coupled with the 50h 70h designator is just so much clearer. What do those latter actually refer to?

I agree with you, even more so when the 3kw motor can output a LOT more than 3-4kW.

138 is airgap diameter

90h is stator width

Has anyone here tried the QS "motor assembly" as they call it?

Most stuff I've read is pretty positive about the mid-mounted QS motors, but wondered if anyone had any experience with the swing arm kit.

I'm looking at converting a vintage scooter - an NZeta (essentially a New Zealand assembled Cezeta) - and I reckon that this should fit in the frame, so would sort out the motor, swing arm and drive train in one fell swoop. Plus the NZeta runs on 12" wheels by default, so I can keep the front end basically stock.

Do you think that 100km/hr is a realistic expectation for this at 72V and with the Votol EM72150SP controller?

The scooter in original form is about 120kg (dry weight, I think). Obviously it's not terribly aerodynamic and that wouldn't change. I reckon this motor and swing arm are lighter than the original. Plus I won't have exhausts or fuel. I think it might come out about even or maybe even slightly lighter.

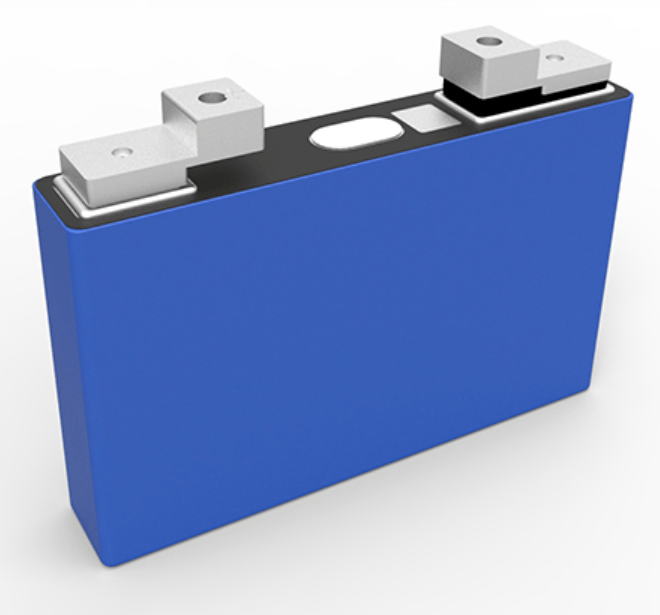

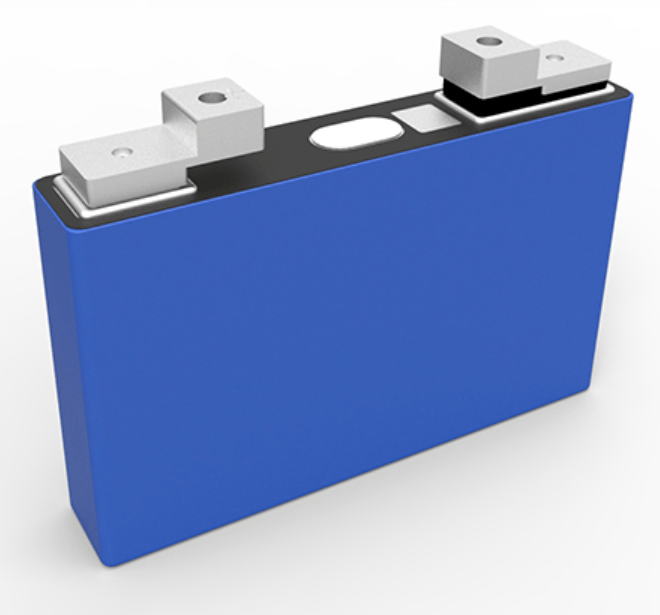

I'm considering using these batteries, which are available here in NZ https://bluecars.nz/shop/new-53-ah-ncm-battery-module/. I think there's room to put 20 of these in series pretty low in the frame in front of the motor, which would be about 20kg and give me about 4KWh of capacity. Haven't worked out what the range would be exactly, but it's in the same ball park as the smaller capacity battery on the Cezeta 506. The battery spec sheets don't list the discharge stats, but I've got a query in to the retailer to make sure they would handle the 80A continuous and 150A peak current draw.

PS. First post. I’d been following this thread on the motor. Hopefully it’s ok to post this question here - hadn’t realised it was in the Motor Tech section. Can move to the E-Scooter and Motorcycle section if not

Most stuff I've read is pretty positive about the mid-mounted QS motors, but wondered if anyone had any experience with the swing arm kit.

I'm looking at converting a vintage scooter - an NZeta (essentially a New Zealand assembled Cezeta) - and I reckon that this should fit in the frame, so would sort out the motor, swing arm and drive train in one fell swoop. Plus the NZeta runs on 12" wheels by default, so I can keep the front end basically stock.

Do you think that 100km/hr is a realistic expectation for this at 72V and with the Votol EM72150SP controller?

The scooter in original form is about 120kg (dry weight, I think). Obviously it's not terribly aerodynamic and that wouldn't change. I reckon this motor and swing arm are lighter than the original. Plus I won't have exhausts or fuel. I think it might come out about even or maybe even slightly lighter.

I'm considering using these batteries, which are available here in NZ https://bluecars.nz/shop/new-53-ah-ncm-battery-module/. I think there's room to put 20 of these in series pretty low in the frame in front of the motor, which would be about 20kg and give me about 4KWh of capacity. Haven't worked out what the range would be exactly, but it's in the same ball park as the smaller capacity battery on the Cezeta 506. The battery spec sheets don't list the discharge stats, but I've got a query in to the retailer to make sure they would handle the 80A continuous and 150A peak current draw.

PS. First post. I’d been following this thread on the motor. Hopefully it’s ok to post this question here - hadn’t realised it was in the Motor Tech section. Can move to the E-Scooter and Motorcycle section if not

Hi I have the Qs motor swingarm kit with the 120 70h motor. The speed indicated for this kit is 70km / h thanks to the FW function, and I can reach them with a converted 50cm3 scooter. The total weight is around 100kg loaded plus my weight of 92kg. With the 138 70h kit and the Votol it is possible to reach 100km / h with the FW properly adjusted. Be careful, however, this controller must be cooled because it heats up and several of my friends had problems because of this.

With Nuc 24F no problème.

With Nuc 24F no problème.

PITMIX said:Hi I have the Qs motor swingarm kit with the 120 70h motor. The speed indicated for this kit is 70km / h thanks to the FW function, and I can reach them with a converted 50cm3 scooter. The total weight is around 100kg loaded plus my weight of 92kg. With the 138 70h kit and the Votol it is possible to reach 100km / h with the FW properly adjusted. Be careful, however, this controller must be cooled because it heats up and several of my friends had problems because of this.

With Nuc 24F no problème.

Interesting. Thanks. Might have to rethink where I place the controller. Was going to put it under the seat, but there’d be no airflow...

Hi, im building an electric car, from old nsu prinz (weight only 550kg) and planning to use qs138 90h version, I'm looking for around 10kw of constant power and maybe 15-20kw peaks.

This is where it gets interesting. i have 32S battery so nominal 118v and full 134volts, do you think this can handle that amount of voltage? Im looking to get Kelly controller with 200 Peak battery and 80A "constant" and max voltage of 138volts

This is where it gets interesting. i have 32S battery so nominal 118v and full 134volts, do you think this can handle that amount of voltage? Im looking to get Kelly controller with 200 Peak battery and 80A "constant" and max voltage of 138volts

Ianhill

1 MW

- Joined

- Sep 25, 2015

- Messages

- 2,871

I think the spline failing is more to do with poor sprocket design than metal fatigue etc its an enduced failure from overstress.

I think the motor can put out its 15kw plus and not damage the shaft if a quality sprocket is used, looking at the pictures theres room left on the rear of the spline its clear from how its chewed through the middle only.

Ok karting sprockets have a larger engagement area onto the spline increasing its load capability, it also uses 219 chain perfect for karts and light weight dirt bikes like my blown up kuberg with demag and ive been waiting for a ipm i could get to fit the gap and use the same setup ill be under 45kg with 12kw for downhill setup 200mm travel allround took me a while to work out this combo can swap to 219 and end up stronger and lighter as a result

I think the motor can put out its 15kw plus and not damage the shaft if a quality sprocket is used, looking at the pictures theres room left on the rear of the spline its clear from how its chewed through the middle only.

Ok karting sprockets have a larger engagement area onto the spline increasing its load capability, it also uses 219 chain perfect for karts and light weight dirt bikes like my blown up kuberg with demag and ive been waiting for a ipm i could get to fit the gap and use the same setup ill be under 45kg with 12kw for downhill setup 200mm travel allround took me a while to work out this combo can swap to 219 and end up stronger and lighter as a result

larsb

1 MW

J Bjork just did a noload measurement on his QS 138 70h / (nucular controller)

It's interesting to see the losses take a leap at 7500 rpm which i've seen QS state is the max rpm for this motor.

Could be an effect of the controller field weakening function not the best at these rpms also. Anyone got a good current meter and a Votol? would be interesting to see the same measurement repeated.

It's interesting to see the losses take a leap at 7500 rpm which i've seen QS state is the max rpm for this motor.

Could be an effect of the controller field weakening function not the best at these rpms also. Anyone got a good current meter and a Votol? would be interesting to see the same measurement repeated.

So a member claimed they ran this motor up to 20kW ??larsb said:

How would the geared version act differently?

larsb

1 MW

I’ve run it at 80V 300A dc input, jbjork about the same.

The geared version won’t be different. (Off course depending on total gearing)

The geared version won’t be different. (Off course depending on total gearing)

larsb

1 MW

rider119 said:Does anyone know the impedance of the QS120 70H and QS138 90H?

It’s about 5mohm for the 138 70H

I found a guy who thinks his engine is running at 20,000rpm. :lol:

I tried to explain to him that the motor runs with a maximum kV of 73 but he is sure that his motor is running at 20,000rpm

If the engine of my motorcycle was running at 20,000 RPM it would roll at 560km/h

https://youtu.be/x3y98TC8YNE

[youtube]x3y98TC8YNE[/youtube]

I tried to explain to him that the motor runs with a maximum kV of 73 but he is sure that his motor is running at 20,000rpm

If the engine of my motorcycle was running at 20,000 RPM it would roll at 560km/h

https://youtu.be/x3y98TC8YNE

[youtube]x3y98TC8YNE[/youtube]

j bjork

100 kW

Seems unlikely, it seems like he set max rpm on the controller to 9000.

It dosent sound like very high rpm to me?

At 8-9000rpm my motor was screaming..

Is 20000 even possible mechanically?

About the volt/amp power discussion earlier, in the log I published in my thread I have:

10:58:17;81.8;365.5;7300;129.5;23;27;6;29898;0 0;

10:58:18;89.4;361.1;6611;117.3;23;28;6;32282;0 0;

First is time, 10:58:17, volt 81.8, Amp 365.5 rpm 7300 speed and temps, power 29898

10:58:18 89.4 361.1 6611 32282

It should be about right, but time glitches messes with some numbers.

Like it dosent seem reasonable that I have 89V when I had 81V a second earlier with about the same load. But probably the V updated when the amps didnt after I let go of the throttle.

It dosent sound like very high rpm to me?

At 8-9000rpm my motor was screaming..

Is 20000 even possible mechanically?

About the volt/amp power discussion earlier, in the log I published in my thread I have:

10:58:17;81.8;365.5;7300;129.5;23;27;6;29898;0 0;

10:58:18;89.4;361.1;6611;117.3;23;28;6;32282;0 0;

First is time, 10:58:17, volt 81.8, Amp 365.5 rpm 7300 speed and temps, power 29898

10:58:18 89.4 361.1 6611 32282

It should be about right, but time glitches messes with some numbers.

Like it dosent seem reasonable that I have 89V when I had 81V a second earlier with about the same load. But probably the V updated when the amps didnt after I let go of the throttle.

So that J Bjork chart abovelarsb said:I’ve run it at 80V 300A dc input, jbjork about the same.

The geared version won’t be different. (Off course depending on total gearing)

only holds for a particular voltage?

Do you know what voltage?

larsb said:rider119 said:Does anyone know the impedance of the QS120 70H and QS138 90H?

It’s about 5mohm for the 138 70H

Thank you sir! Still curious about the 120 if anyone knows?

Overclocker

10 kW

Ianhill said:I think the spline failing is more to do with poor sprocket design than metal fatigue etc its an enduced failure from overstress.

I think the motor can put out its 15kw plus and not damage the shaft if a quality sprocket is used, looking at the pictures theres room left on the rear of the spline its clear from how its chewed through the middle only.

s-l400.gif

Ok karting sprockets have a larger engagement area onto the spline increasing its load capability, it also uses 219 chain perfect for karts and light weight dirt bikes like my blown up kuberg with demag and ive been waiting for a ipm i could get to fit the gap and use the same setup ill be under 45kg with 12kw for downhill setup 200mm travel allround took me a while to work out this combo can swap to 219 and end up stronger and lighter as a result

agree. shaft spline wear comes from loose-fitting sprockets (yes the sprockets supplied by QS are loose).

so i fixed it by utilizing all the available splines w/ super tight fitting parts. however this covers the circlip groove so there's no other way to retain the sprocket but to weld :lol:

QS should revise the design for wider spline engagement and provide a threaded hole for a bolt to hold the sprocket in

So means buy the belt drive version of the motor, use the adapter to accommodate a chain drive?PITMIX said:Qs already solved the problem look at the sprocket for the Qs 138 90H here.

https://a.aliexpress.com/_vo6uyV

Overclocker

10 kW

14t is the smallest?

i'm now using 56t at the back, 11t motor sprocket. to maintain same ratio i'd need a giant 72t. and this is w/ the low-kv "2000w" 120-70h motor (kv is 38)

i'm now using 56t at the back, 11t motor sprocket. to maintain same ratio i'd need a giant 72t. and this is w/ the low-kv "2000w" 120-70h motor (kv is 38)

Similar threads

- Replies

- 12

- Views

- 760

- Question

- Replies

- 1

- Views

- 166

- Replies

- 15

- Views

- 269

- Replies

- 0

- Views

- 139