raylo32

100 kW

This motor??

https://www.washingtonpost.com/technology/2021/07/01/tesla-plaid-fire/

https://www.washingtonpost.com/technology/2021/07/01/tesla-plaid-fire/

Tesla did not waste any time highlighting the Model S Plaid’s killer metric: 0-60 mph in 1.99 seconds. This figure, which can be attained on a prepped drag strip as per MotorTrend‘s formal tests, has effectively dominated news about the flagship sedan — so much so that some of the vehicle’s other notable capabilities have been overshadowed. Among these are its 60-130 mph time, which is arguably the Model S Plaid’s true killer metric.

What has to be said is that the Model S Plaid is a car that continues to pull really strongly far beyond 60 mph. This could be experienced in the vehicle’s acceleration and power at higher speeds. Tests of the Tesla Model S Plaid have revealed that the flagship sedan could go from 60-130 mph in 4.71 seconds. This is undoubtedly impressive on its own, but when one compares this to the 60-130 mph performance of some of the world’s best supercars and electric cars, one could see just how far Tesla has gone with the Model S Plaid.

A stock McLaren 765LT, arguably one of the best supercars today, goes from 60-130 mph in 4.76 seconds. The McLaren P1, one of the “Holy Trinity” of hypercars, does the same in 4.8 seconds. The Ferrari SF90 accelerates from 60-130 mph in 4.97 seconds, while the Ferrari LaFerrari, another one of the hypercar “Holy Trinity,” achieves the same feat in about 5 seconds. These numbers, however, are not the most shocking part of the Model S Plaid’s 60-130 mph performance.....

his could be seen in the Model S Raven Performance’s drag races against the Porsche Taycan Turbo S, a vehicle with a two-speed transmission that achieves 60-130 mph in 8.1 seconds.....

This would not be happening with the Model S Plaid. Looking at the vehicle’s 4.71-second 60-130 mph capability, it seems safe to state that Tesla, in its continued pursuit to improve its flagship sedan, effectively made the Model S Plaid twice as quick at 60-130 mph as its previously quickest Model S. Interestingly enough, the Model S Plaid’s high-speed capabilities are rarely highlighted by the company, perhaps because its 1.99-second 0-60 mph time is a more compelling metric.

What is truly remarkable with the Model S Plaid’s 60-130 mph time is that Tesla was able to achieve these figures through its own means. Porsche was able to provide the Taycan Turbo S with amazing high-speed performance using a two-speed gearbox, a mark of its pedigree as a veteran sports car maker. Tesla, on the other hand, was able to attain the Model S’ unearthly metrics using carbon-wrapped electric motors and continued improvements to its battery tech, highlighting its roots in tech and Elon Musk’s physics-heavy background.

“As far as we know, this is the first time there has been a production electric motor with a carbon-coated rotor. This is an extremely difficult thing, because carbon and copper have very different rates of thermal expansion. To have a carbon-coated rotor, you need to wrap it with extremely high intensity and this is extremely difficult to do."

Today via Twitter, the head of the company shared some more details. Musk said that the fiber is wound over the rotor at a high tension load, which previously could not be achieved on a large production scale. Tesla Automation, which is based in Germany, made a machine for this. At the beginning of May, it was noticed that construction had begun near the company's facility in Prüm. It is likely that the new building will house production lines for new machines that are needed to produce the innovative motors that will power Model S Plaid and Roadster, according to Musk.

The main benefit of the new motor is that the carbon sleeve rotor creates a stronger electromagnetic field than a rotor that is held together by metal, the head of the company explained. Another advantage is that the rotor can go to higher RPM as the carbon sleeve stops the copper rotor from expanding due to radial acceleration. Thus, Tesla's new motor is the most advanced motor in production on Earth.

Nevertheless, the company does not intend to be satisfied with what has already been achieved, which generally applies to any product created by it. Musk said that Tesla already has several ideas to further increase torque and maximum RPM for the new Roadster, which should begin production soon. As such, there’s no doubt the Roadster will have the most effective and innovative equipment, the analogs of which do not exist today.

Hillhater said:Its always a trial reading Hillhater's posts to filter out the facts from the predictions, speculation, teasers, and mostly plain BS.

Single helical stage per motor per rear wheel to eliminate the differential is fantastic. Differentials are vestigial internal combustion components.

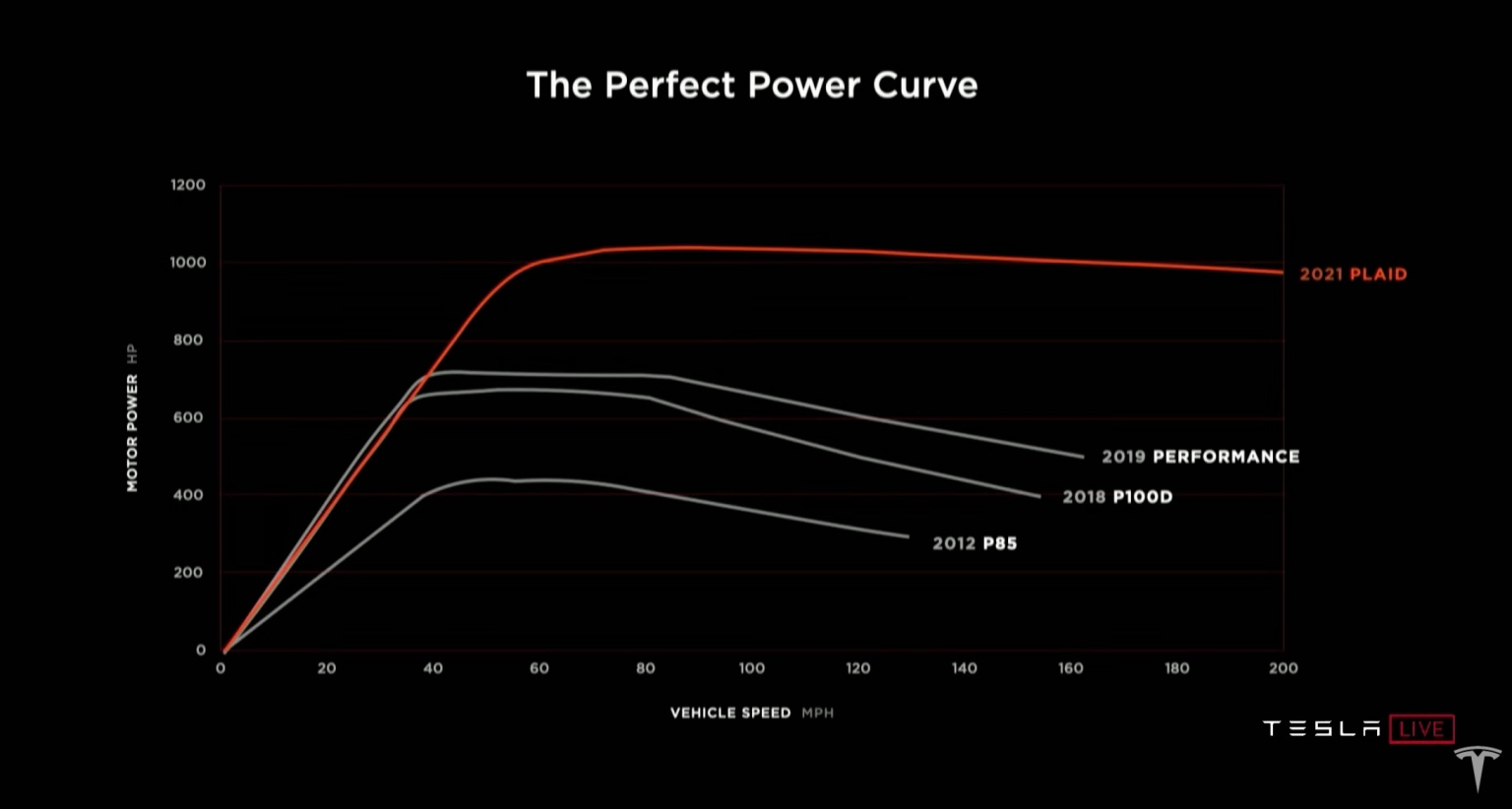

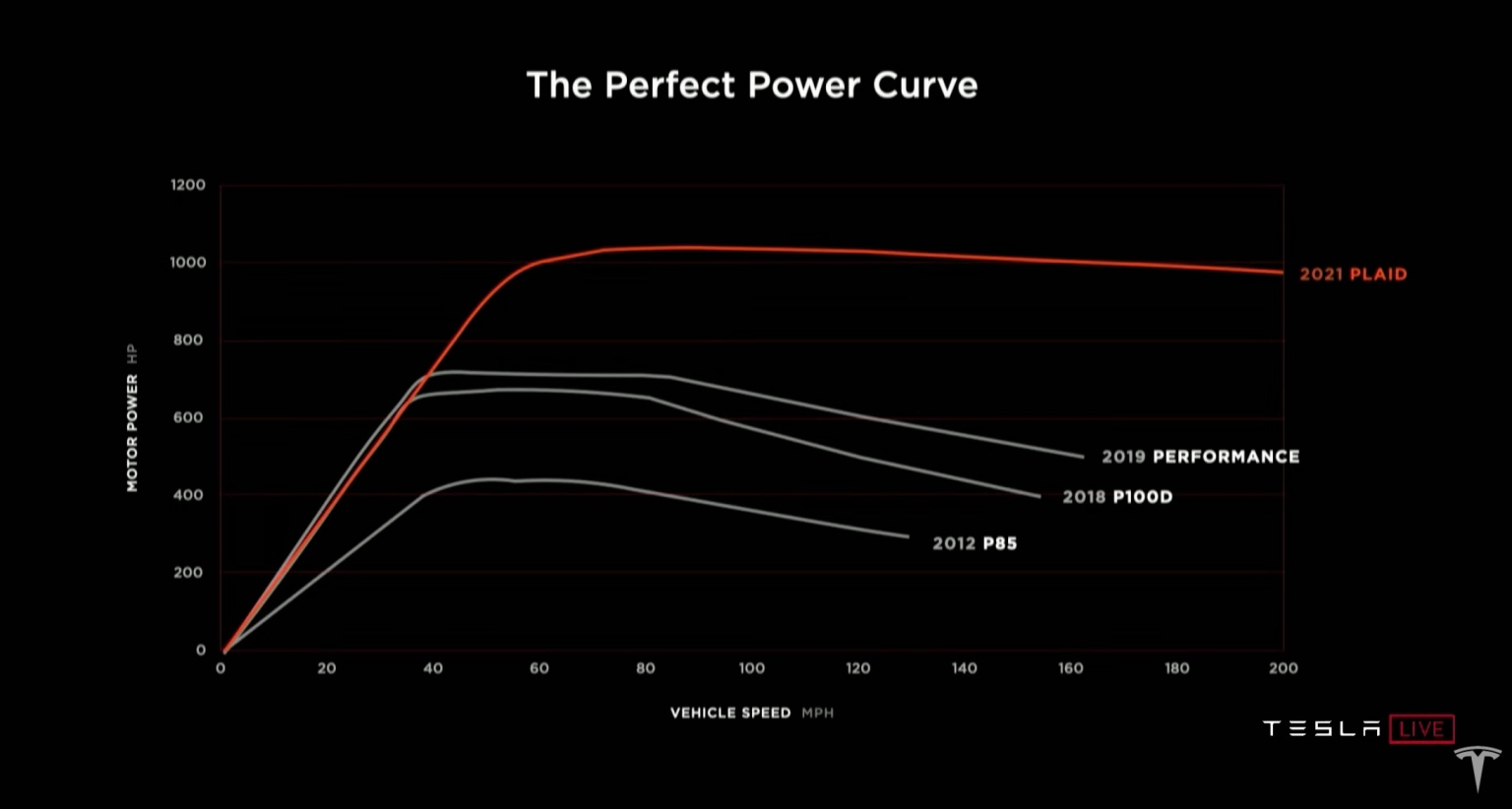

Every motor requires reduction gears and frequently an additional reduction at the differential for optimum performance. This motor requires less reduction gearing than conventional motors. Check the power curve:Chalo said:MitchJi said:You count the reduction gears as part of the motor?!

When you compare a motor that requires reduction gears against motors that don't, it's unrealistic and disingenuous not to include the gears.

Single helical stage per motor per rear wheel to eliminate the differential is fantastic. Differentials are vestigial internal combustion components.

Every motor requires reduction gears and frequently an additional reduction at the differential for optimum performance. This motor requires less reduction gearing than conventional motors. Check the power curve (y axis is hp, x axis is vehicle speed) :Chalo said:MitchJi said:You count the reduction gears as part of the motor?!

When you compare a motor that requires reduction gears against motors that don't, it's unrealistic and disingenuous not to include the gears.

And using a second motor + transmission + inverter, etc etc....is a simplification,? weight saving,? cost reduction ?MitchJi said:Single helical stage per motor per rear wheel to eliminate the differential is fantastic. Differentials are vestigial internal combustion components.

Plenty of motors that do not need reduction gears..Ebike / moto DD hubs are a obvious example, and there have been cars built using wheel hub motors.MitchJi said:...Every motor requires reduction gears and frequently an additional reduction at the differential for optimum performance. This motor requires less reduction gearing than conventional motors. Check the power curve (y axis is hp, x axis is vehicle speed) :

Hillhater said:Plenty of motors that do not need reduction gears..Ebike / moto DD hubs are a obvious example, and there have been cars built using wheel hub motors.MitchJi said:...Every motor requires reduction gears and frequently an additional reduction at the differential for optimum performance. Thi motor requestings less reduction gearing than conventional motors. Check the power curve (y axis is hp, x axis is vehicle speed) :

What do you mean by “less reduction gearing” ?....compared to which conventional motors ?

P.S....that Power/Road speed chart tells us nothing about reduction gearing ?

But you have to define “optimum performance”..?MitchJi said:......

I clearly stated for optimum performance! DD hub motors sacrifice performance for simplicity. You could obviously run that motor on a MS-MX with zero reduction and still have great performance.

PS The chart would buy useful for determining the reduction required for optimum performance.

Junk yard in 6-12 months.nicobie said:I swear, if I could get my hands on one of those rear power units.

Nick

nicobie said:Luke, do you own one of these monsters?

I'm jealous.

I swear, if I could get my hands on one of those rear power units, I'd build one last race car and go out in style.

Nick

liveforphysics said:The crazy thing is, the existing model S chassis is much lower drag than any of the old MGs or similar small older cars. It's lower drag and less energy to move the model S chassis around than my 2001 Honda Insight, which had none of the utilitarian function, interior space and passenger space all sacrificed for efficiency, and the model S is more efficient as a 5 seater luxo-box.

I also want to see how it feels with the same HP in a 2000lbs car vs it's current 4700lbs weight, and I agree high enough C-rate cells exist for it, but I don't see it ending up with lower Wh/mile (for highway at least) than the stock Model S.

I suspect that you,..like most of us,.. do not actually know the weight of the Plaid drive train ( motor + tranmission).The Toecutter said:That motor is so light and the 2170 batteries in the Model 3 so dense that the two combined open up the possibility of a 300 mile range conversion that is hundreds of lbs less in weight than as it came with a gasoline engine! I'd only need about 250 horsepower to do 0-60 mph ~ 3 seconds like that...

nicobie said:I wonder what that auction will go for?

Probably out of my league...