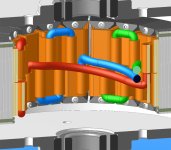

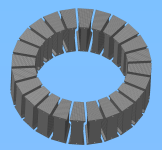

I kept the endturn for the sake of uniformityMiles said:Accepting some imbalance, I'm leaning towards increasing the number of turns from 4 to 6 and missing out the first half turn from the first module of each phase. Might as well gain the advantage of losing an endturn, too

Reasonable compromise?

It makes for a neat connection.