This is a quick comparison of version 1 and version 2 and 3. There have been a few iterations of the cro motors over time, some minor tweaks to the axels, spoke holes, hub off sets etc, and then the later version 2 and 3 which looks quite similar on the outside but has totally different innards. My preference is for off road riding on downhill style bikes, and with over 8 inches of rear travel unsprung weight is VERY noticeable. Brian, Pickle and I pulled apart several version 1 and version 2,3 motors to compare. The 1st thing you notice is the weight!

Version 1 cro motor 10.6KG, lamination thickness 0.5mm, copper wind 18 strands 4 turn, stator width 50.3mm

Version 2,3 cro motor 12.2KG! Lamination thickness 0.35mm!, copper wind 18 strands 4 turn, stator width 48.3mm

The newer versions had much finer laminations and a LOT smaller stator inside diameter (this is where most of the (unnecessary?) pork is). The stator teeth are also about 2mm longer, but it still has the same copper fill/wind and the obvious beefy alloy hub. This would be a much superior heat sink.

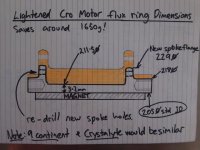

Brian and I put the flux rings up in the old lathe and machined off most of the original spoke flanges and turned the rest of the flux ring down to only 3.1mm thick (this is a lot of steel removed). We then redrilled some new spoke holes in the new minimalist spoke flange. There was no noticeable flux leakage after this only when I assembled the flux ring back onto the stator you can feel a slight amount. Weight loss is just under 2KG! I also had a 500w golden motors freewheel side, side plate laying around which is thinner and without the Cro motors big steel freewheel adaptor hub (only the bearing diameter needs machining to suit, and the bolt holes drilled larger for the Cro motors larger bolts)that saves another 250g. Some cooling holes were also drilled. The KV has not changed; it is still 9.3KV, this gets the early version down to 8.4KG! And the later model down to approximately 10.2KG. Don’t get me wrong this is still a big lump for jumping etc, but I think anyone could feel the difference on or off road and it has to be kinder for rear wheel pinch flats and rim damage etc.

Checking the difference in no load losses: Brian and I connected the different versions up to a little 18fet controller and 24s of A123, and measured the no load losses of a bare hub no tyres, rim, or spokes, using a Cycle Analyst and 80 volts.

Version 1: 200Watts

Version 2,3: 131Watts!

A very knobby tyre, rim and spokes adds around 50watts depending on diameter and tread etc.

The version 1 does have 4% more stator width.

If maximum efficiency is when copper losses = no load loss, does this mean the point of maximum efficiency of the version 1 cro motor is overall obviously lower, but happens at a overall higher output? If you use high voltages the difference is going to be a LOT bigger. My wife’s bamboo bike was using around 700w at 120V or 145km/hr free rpm with a V1.

Off road with average speeds of only around 25km/hr in the bush the difference in losses would be slight, and it might be lighter to just carry more battery and use the old version. Commuting at high speed, using high volts, or small wheels the opposite may be true.

Which version would people choose? Whats your priority?

Zappy

Version 1 cro motor 10.6KG, lamination thickness 0.5mm, copper wind 18 strands 4 turn, stator width 50.3mm

Version 2,3 cro motor 12.2KG! Lamination thickness 0.35mm!, copper wind 18 strands 4 turn, stator width 48.3mm

The newer versions had much finer laminations and a LOT smaller stator inside diameter (this is where most of the (unnecessary?) pork is). The stator teeth are also about 2mm longer, but it still has the same copper fill/wind and the obvious beefy alloy hub. This would be a much superior heat sink.

Brian and I put the flux rings up in the old lathe and machined off most of the original spoke flanges and turned the rest of the flux ring down to only 3.1mm thick (this is a lot of steel removed). We then redrilled some new spoke holes in the new minimalist spoke flange. There was no noticeable flux leakage after this only when I assembled the flux ring back onto the stator you can feel a slight amount. Weight loss is just under 2KG! I also had a 500w golden motors freewheel side, side plate laying around which is thinner and without the Cro motors big steel freewheel adaptor hub (only the bearing diameter needs machining to suit, and the bolt holes drilled larger for the Cro motors larger bolts)that saves another 250g. Some cooling holes were also drilled. The KV has not changed; it is still 9.3KV, this gets the early version down to 8.4KG! And the later model down to approximately 10.2KG. Don’t get me wrong this is still a big lump for jumping etc, but I think anyone could feel the difference on or off road and it has to be kinder for rear wheel pinch flats and rim damage etc.

Checking the difference in no load losses: Brian and I connected the different versions up to a little 18fet controller and 24s of A123, and measured the no load losses of a bare hub no tyres, rim, or spokes, using a Cycle Analyst and 80 volts.

Version 1: 200Watts

Version 2,3: 131Watts!

A very knobby tyre, rim and spokes adds around 50watts depending on diameter and tread etc.

The version 1 does have 4% more stator width.

If maximum efficiency is when copper losses = no load loss, does this mean the point of maximum efficiency of the version 1 cro motor is overall obviously lower, but happens at a overall higher output? If you use high voltages the difference is going to be a LOT bigger. My wife’s bamboo bike was using around 700w at 120V or 145km/hr free rpm with a V1.

Off road with average speeds of only around 25km/hr in the bush the difference in losses would be slight, and it might be lighter to just carry more battery and use the old version. Commuting at high speed, using high volts, or small wheels the opposite may be true.

Which version would people choose? Whats your priority?

Zappy