Early summer last year, I hurt the outside of my wrist, putting weight on it brings the pain back.

I wanted to build a simple, light, inexpensive rear DD motor full suspension bike using a free frame I was given by a guy on FB.

I found a 500w DD motor on ebay for $103 and it looked good on paper (claims 40N torque).

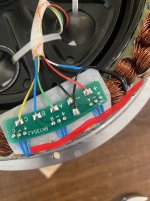

I took it apart to check it out as it looked like it has a temp sensor (it does).

Also to spray varnish on the inside.

I used an 8 inch gear puller to pull it apart and I found bamboo pegs holding the motor copper,

the pegs are loosy goosy, moving nearly freely.

Q - what glue can I use to stick the bamboo to the steel?

Also, further inspection, I found server magnets where chipped and missing corners.

WTF, is this advanced motor magnet design for Field Weakening? [sarcasm]

I wanted to build a simple, light, inexpensive rear DD motor full suspension bike using a free frame I was given by a guy on FB.

I found a 500w DD motor on ebay for $103 and it looked good on paper (claims 40N torque).

I took it apart to check it out as it looked like it has a temp sensor (it does).

Also to spray varnish on the inside.

I used an 8 inch gear puller to pull it apart and I found bamboo pegs holding the motor copper,

the pegs are loosy goosy, moving nearly freely.

Q - what glue can I use to stick the bamboo to the steel?

Also, further inspection, I found server magnets where chipped and missing corners.

WTF, is this advanced motor magnet design for Field Weakening? [sarcasm]

Attachments

Last edited: