Hello, I'm building a fixed wing VTOL bellysitter.

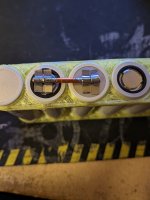

It's going to have 2 6s1p battery packs one in each wing. I'll be using INR-21700-42A. The thing is I may be drawing 30-40 amps from each pack during the take-off and landings.

According to the ampacity of battery strips sheet by Matador I need a 4 to 5 mm^2 of copper or 16 mm^2 or nickel strips. Please correct me if I'm wrong on this.

My Chinese welder is good up to 0.15 mm strips max.

How should I make it work?

Stacking crazy amount (7 to 10) of strips on top of each other sounds bad. Getting a better welder?

I'm really tempted to grab a 120W soldering iron...

Appreciate your help.

It's going to have 2 6s1p battery packs one in each wing. I'll be using INR-21700-42A. The thing is I may be drawing 30-40 amps from each pack during the take-off and landings.

According to the ampacity of battery strips sheet by Matador I need a 4 to 5 mm^2 of copper or 16 mm^2 or nickel strips. Please correct me if I'm wrong on this.

My Chinese welder is good up to 0.15 mm strips max.

How should I make it work?

Stacking crazy amount (7 to 10) of strips on top of each other sounds bad. Getting a better welder?

I'm really tempted to grab a 120W soldering iron...

Appreciate your help.