karlInSanDiego

10 mW

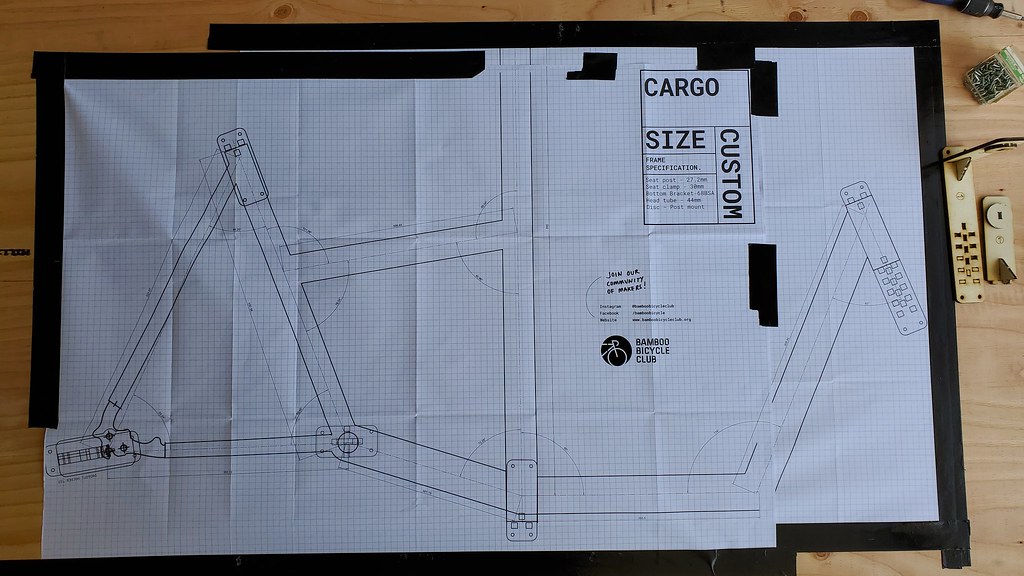

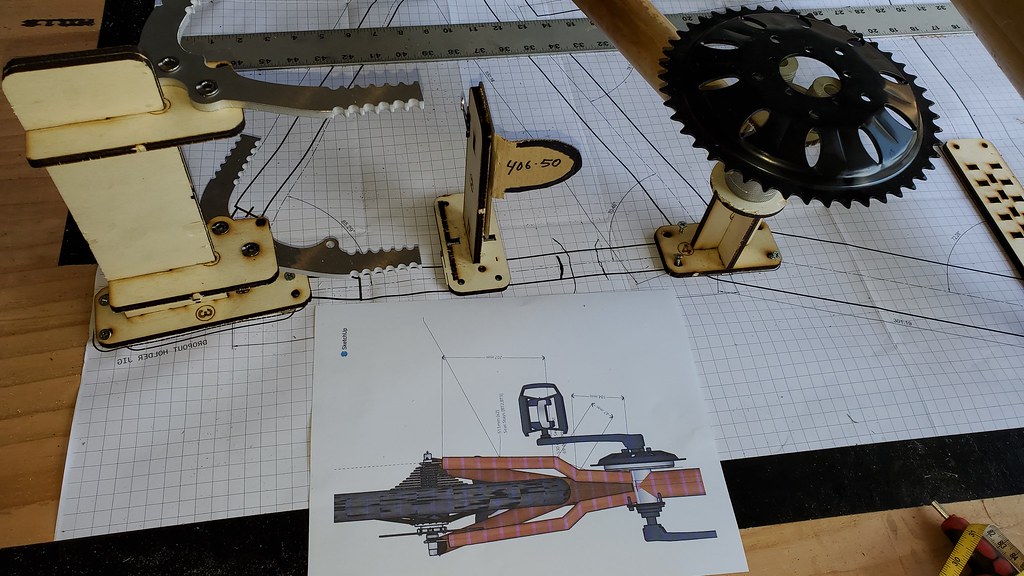

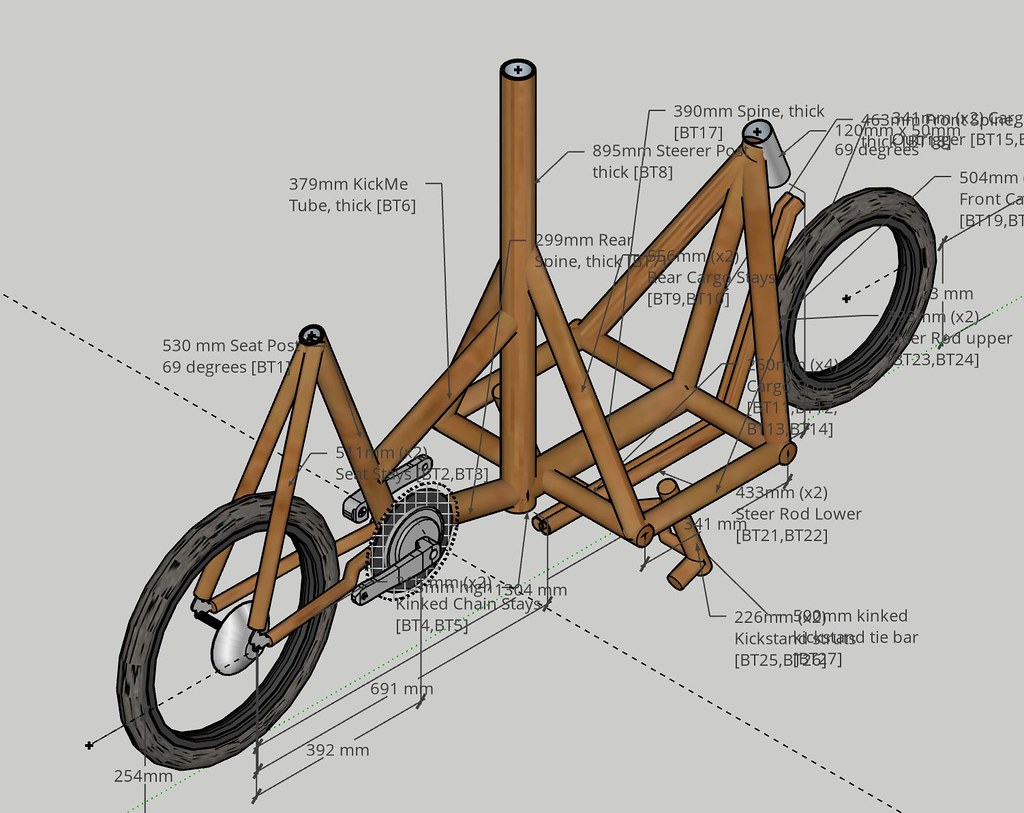

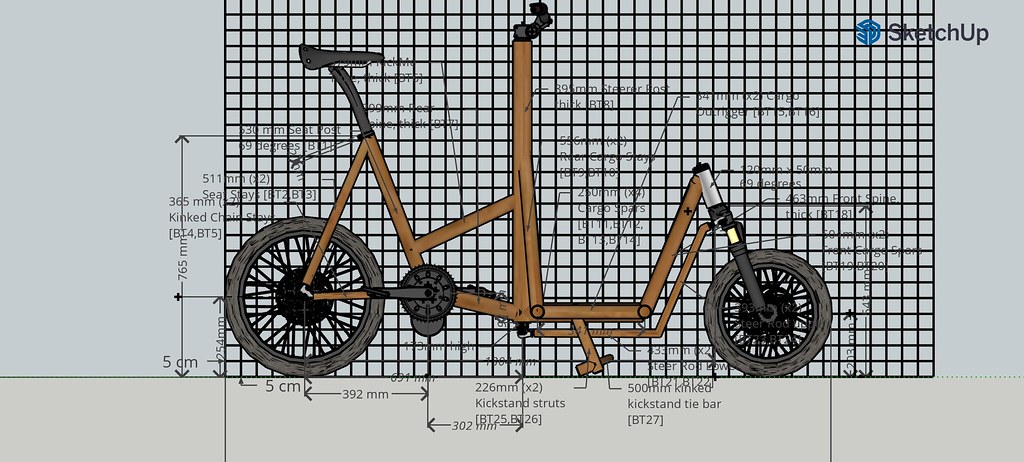

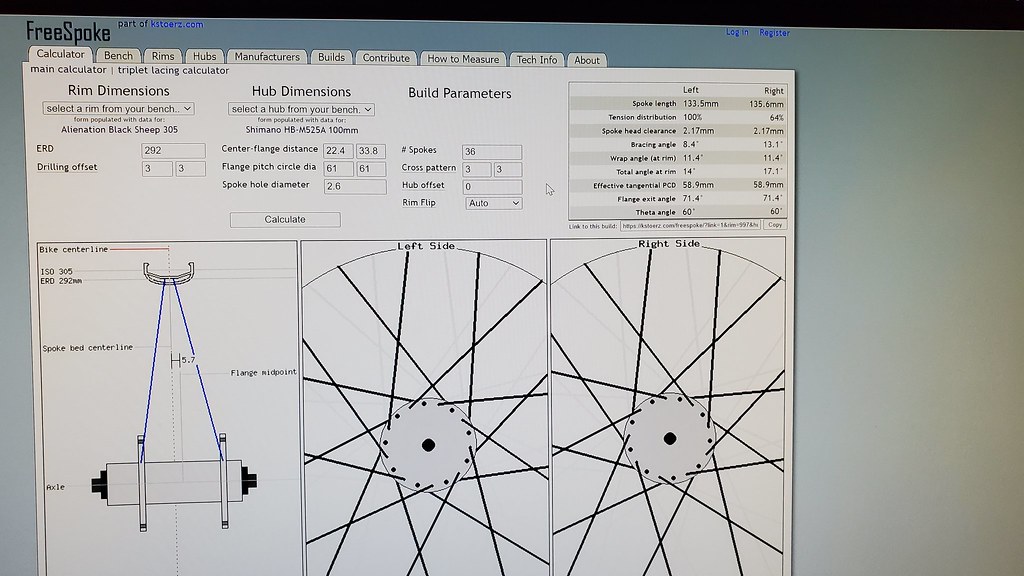

Much thanks to James at the Bamboo Bicycle Club. Here are some shots of my finished Compact Bamboo Long-John Cargo E-Bike. I designed it on SketchUp. It's inspired by a German Muli design. It has a 1000W mid-drive Bafang motor, 2 used 491Wh e-scooter batteries, located in a homemade battery box in the basket base. I learned to weave for this project, and the reed is rattan, so grass like the bamboo frame. It has 9 speeds on a cassette and a 3 speed Sturmey Archer CS-RK3 internal gear hub. I built the wheels using Alienation BMX rims, with 305mm front and 406mm rear. It's running Magura MT5e brakes with 180mm MDR-C rotors and sport pads. Front fork is a SR-Suntour SF18 XCM JR-AIR-SL Lo 20 with air adjustment and lockout. It has a SRAM 20th Anniversery XO rear deraileur from 2007 and SRAM X9 trigger takeoffs from even earlier, which I chose because of their visible gear indicator windows. I added an EggRider v2 display which allows easy motor tuning via bluetooth and includes a range indicator. Saddle is Brooks Cambium C17 Special. Front light is Busch + Müller IQ-XS high beam and the high/low switch integrates with the Magura brake lever. Seat post is a carbon fiber knockoff of the Ergon suspension post. Headset is Viscoset steering damper.

Some bikes deliver a pizza. This bike delivers the pizza oven.

Sized to fit on the trains in San Diego

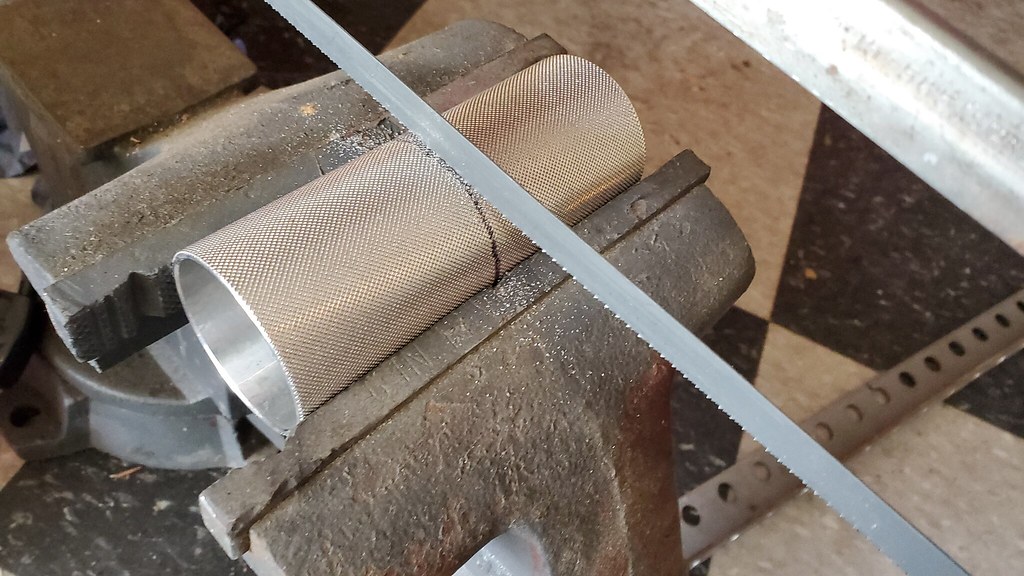

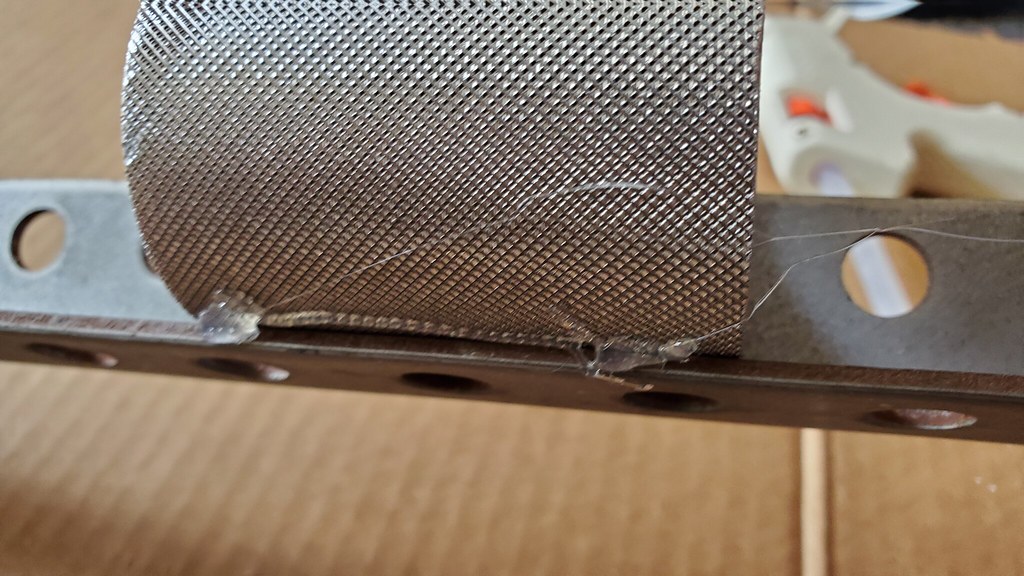

Design and Build

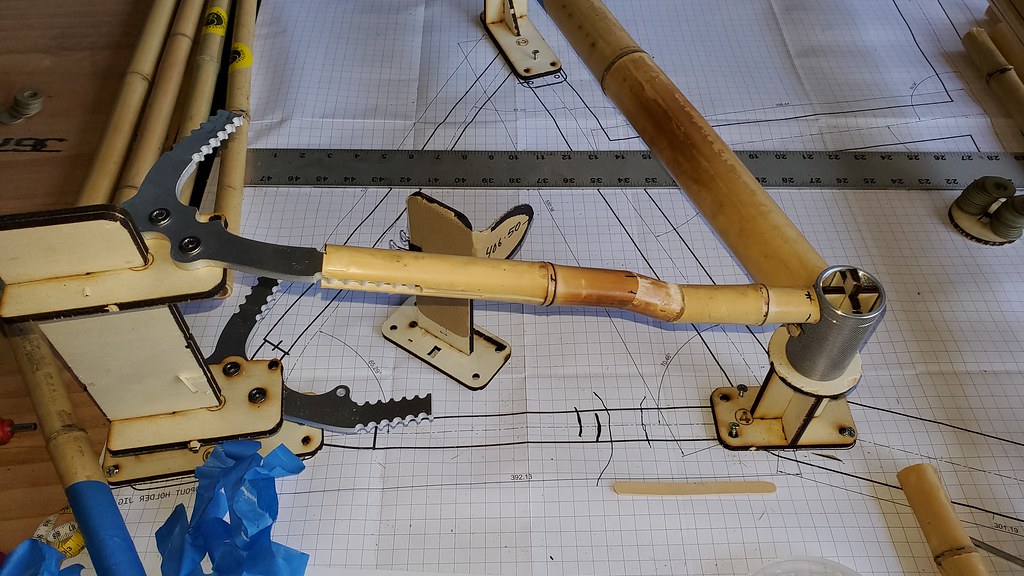

Used fork cut and welded to steel tubing to form custom steerer